Preface / Table of Contents

Thank you for having selected our “AIRMAN” product.

Keep this manual at hand to refer to it always when necessary.

When this manual is missing or damaged, order it from our office nearby or distributor. Make sure

that the manual is included with the machine when it is handed over to another user.

The contents of this manual may differ from the machine because of design changes. If anything is

unclear, please contact our office or your nearest dealer for clarification.

For details of handling, maintenance and safety of the engine, see the Engine Operation Manual.

―Table of Contents ―

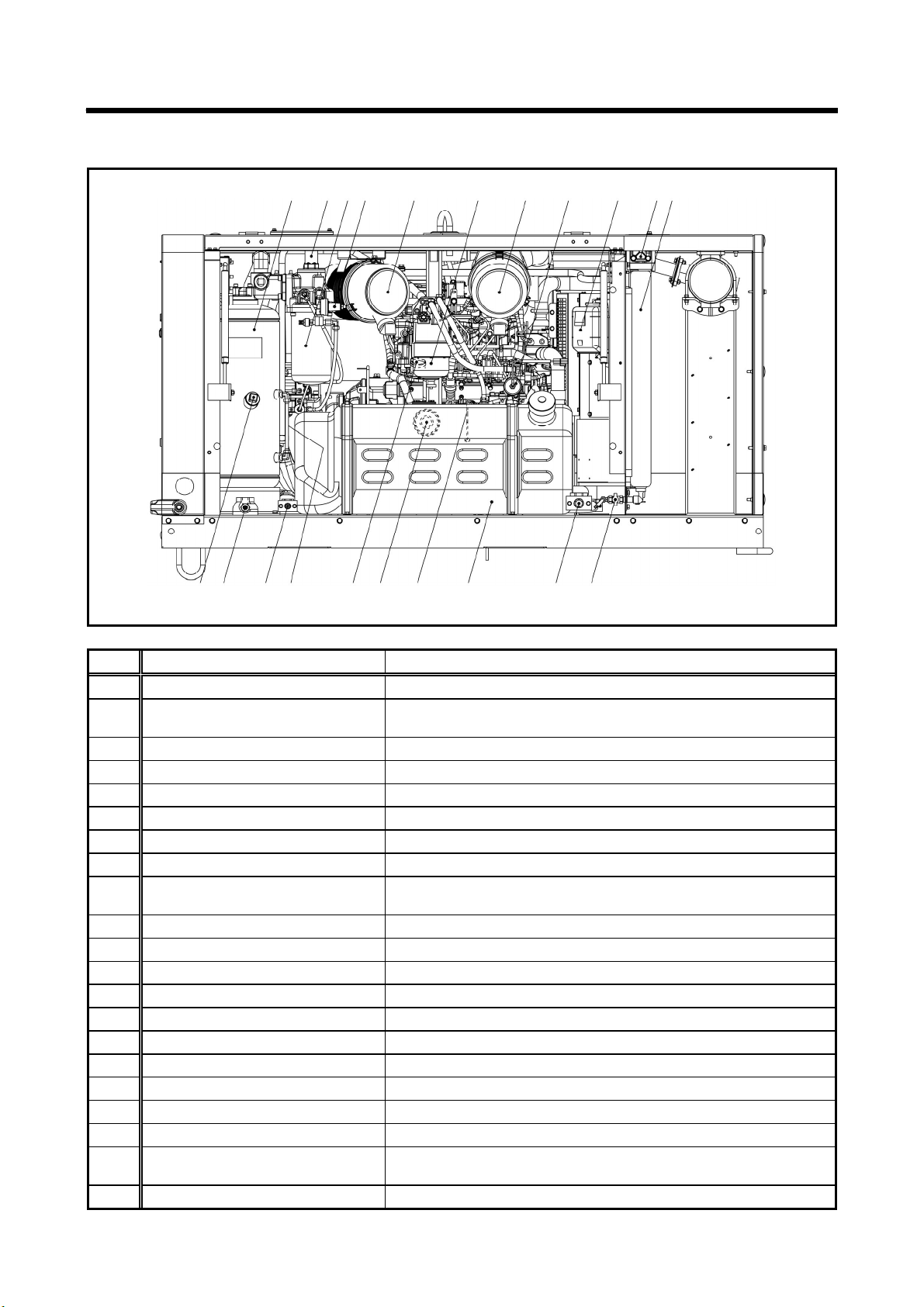

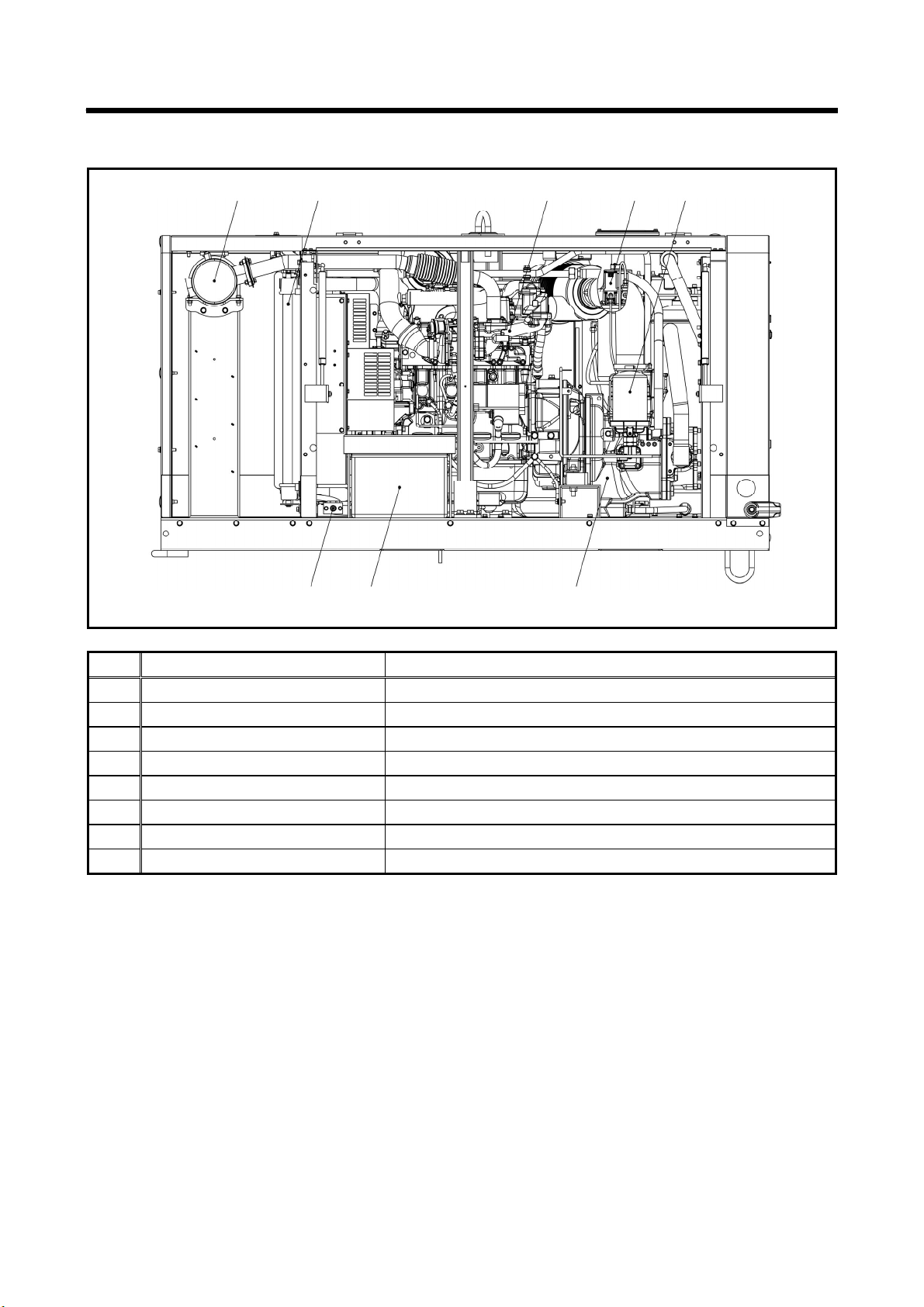

1. Part Names --------------------------------------------------------------------------------------- 1-1

1.1 Internal Components and Part Names ---------------------------------------------------------------------- 1-1

2. Installation ---------------------------------------------------------------------------------------- 2-1

2.1 Transportation ---------------------------------------------------------------------------------------------------- 2-1

2.2 Towing the Machine --------------------------------------------------------------------------------------------- 2-2

2.3 Installation conditions ------------------------------------------------------------------------------------------- 2-3

3. Operation ----------------------------------------------------------------------------------------- 3-1

3.1 Instrument Panel ------------------------------------------------------------------------------------------------- 3-1

3.2 Lubricating oil・Coolant・Fuel ------------------------------------------------------------------------------- 3-2

3.3 Check before starting unit -------------------------------------------------------------------------------------- 3-4

3.4 Operating Procedure -------------------------------------------------------------------------------------------- 3-11

4. Failure cause and measures --------------------------------------------------------------- 4-1

4.1 Indicator lamp and Warning / Emergency display -------------------------------------------------------- 4-1

4.2 Troubleshooting -------------------------------------------------------------------------------------------------- 4-3

5. Periodic Inspection/Maintenance --------------------------------------------------------- 5-1

5.1 Important Items as Periodic Inspection and Maintenance or after Maintenance ----------------- 5-1

5.2 Inspection on Separator Receiver Tank -------------------------------------------------------------------- 5-2

5.3 Periodic Inspection List ----------------------------------------------------------------------------------------- 5-3

5.4 Replacement Parts Schedule --------------------------------------------------------------------------------- 5-5

5.5 Maintenance Items ----------------------------------------------------------------------------------------------- 5-6

6. Storage and Disposal ------------------------------------------------------------------------- 6-1

6.1 Preparation for Long-term Storage -------------------------------------------------------------------------- 6-1

6.2 Disposal of Product ---------------------------------------------------------------------------------------------- 6-1

7. Specifications ----------------------------------------------------------------------------------- 7-1

7.1 Specifications ----------------------------------------------------------------------------------------------------- 7-1

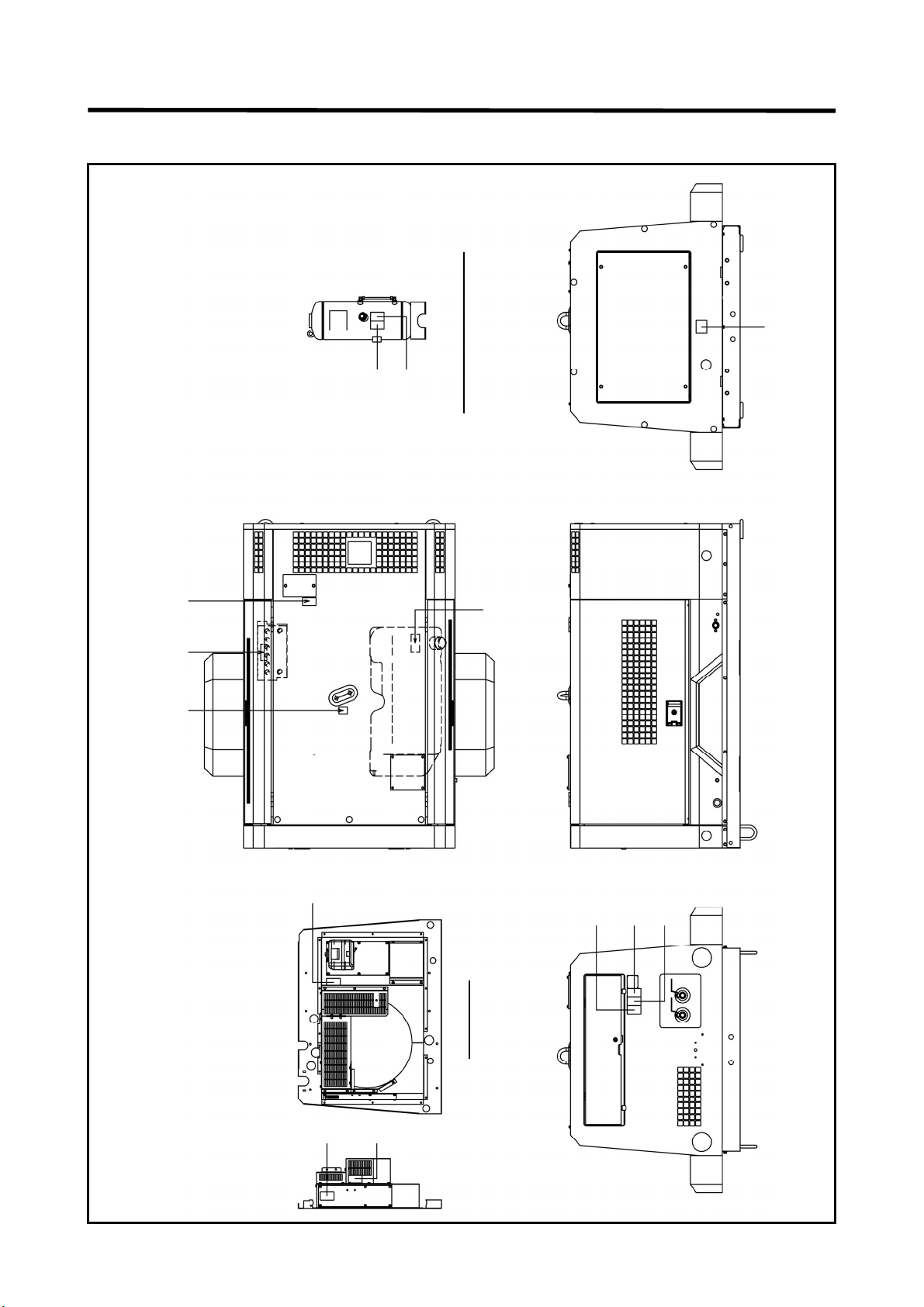

7.2 Exterior drawing -------------------------------------------------------------------------------------------------- 7-2

7.3 Wiring Diagram --------------------------------------------------------------------------------------------------- 7-4

7.4 Piping Diagram --------------------------------------------------------------------------------------------------- 7-5