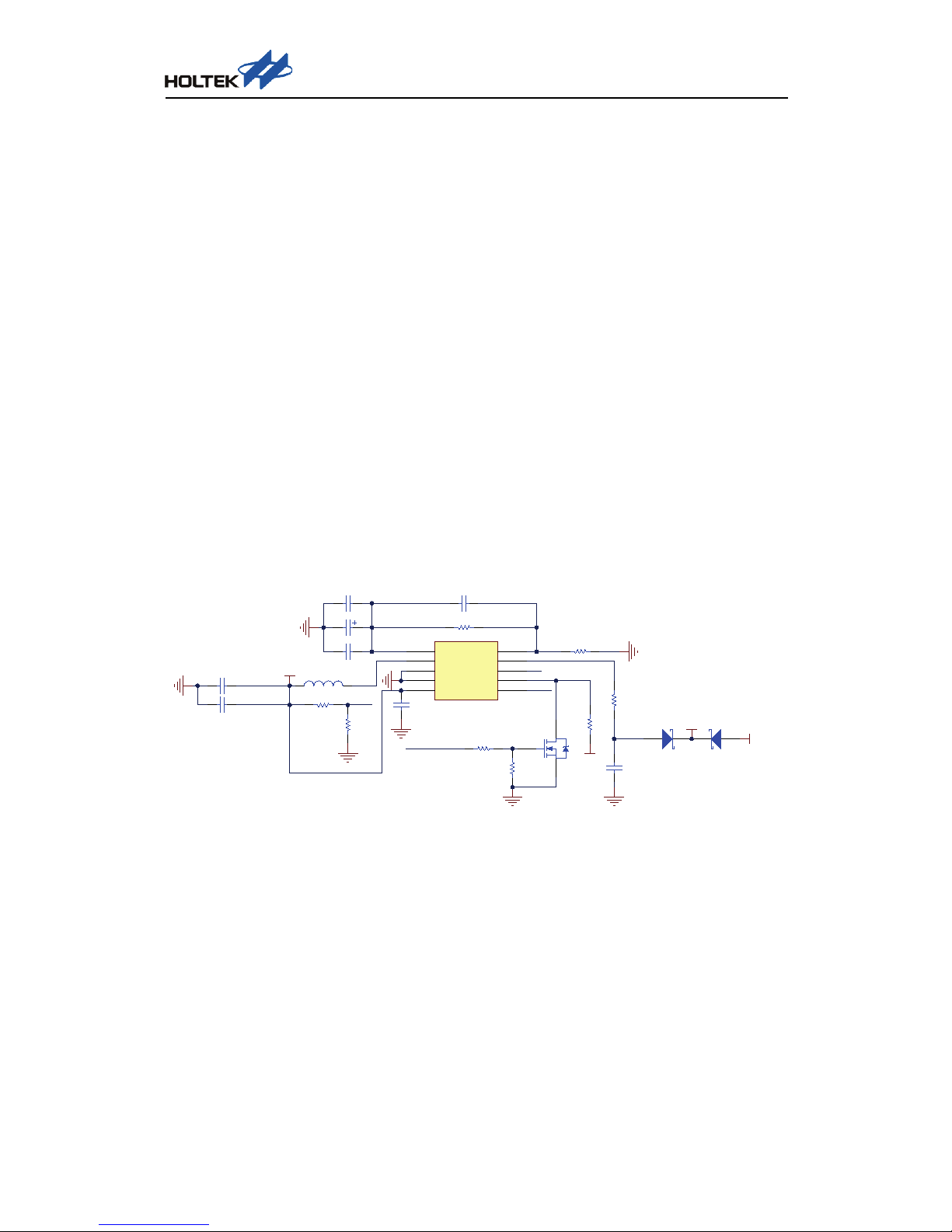

HT1635A/B Wearable Sports Bracelet LED Display Application

2 / 19 AN0393E

HT1635A/HT1635B Features Description

Communication Interface

Based on their interface difference, the HT1635 series falls into two versions, the

HT1635A and the HT1635B. The HT1635A includes a 4-wire serial communication

interface which has four pins, WRB (Write Serial Clock), DATA (Serial Data), RDB (Read

Serial Clock) and CSB (Chip Select). The HT1635B is supplied in the same package type

as the HT1635A and is basically pin compatible with the HT1635A, with the exception

that the HT1635B includes an I2C communication interface which has four different pin

names corresponding to the HT1635A serial interface pins, SCL (Serial Clock), SDA

(Serial Data), A1 (Device Address Data Input Pin) and A0 (Device Address Data Input

Pin), as shown in the table below.

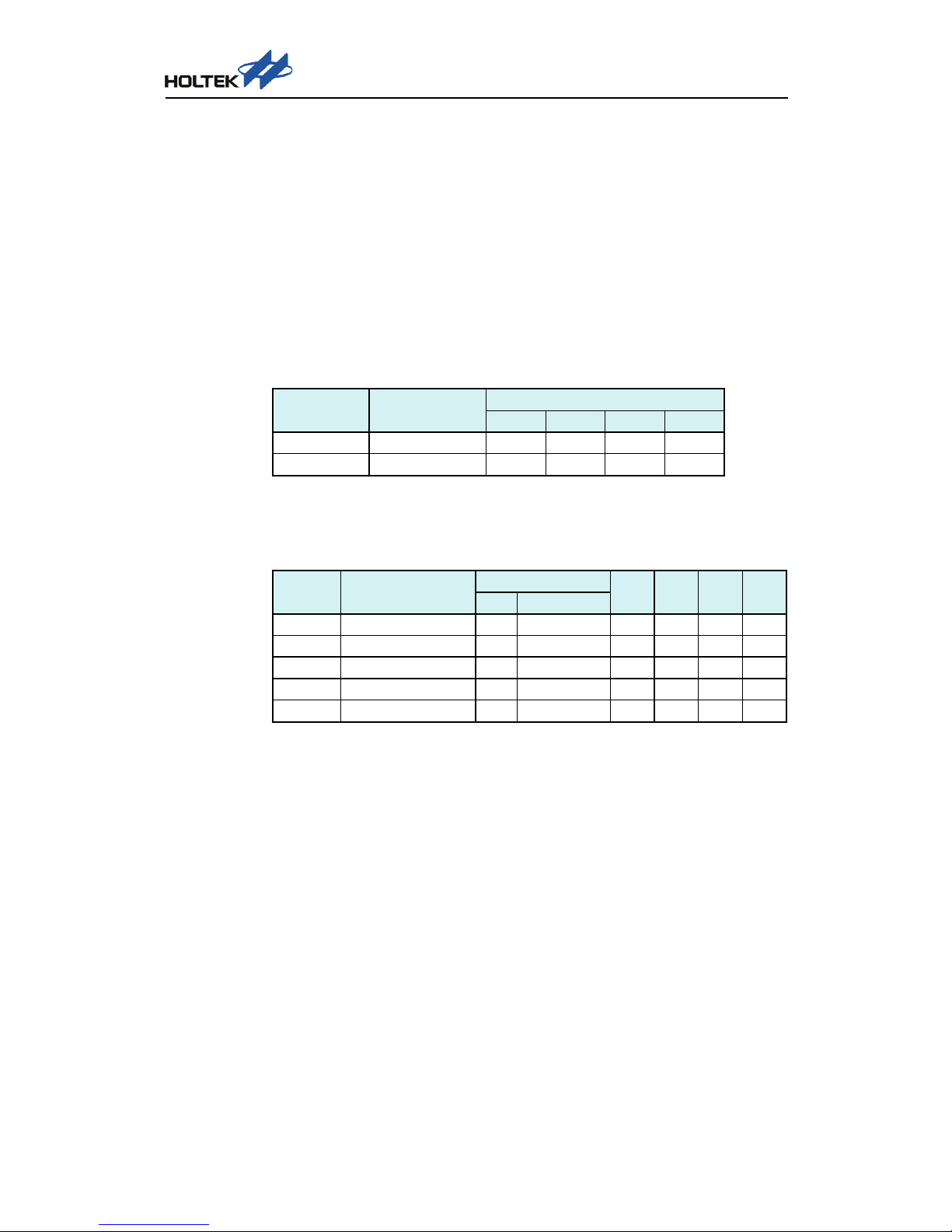

Part Number Interface Type Interface Pin

17 18 19 20

HT1635A 4-wire DATA WRB RDB CSB

HT1635B I2C SDA SCL A1 A0

COM and ROW I/O Driving Capacity

The HT1635A/HT1635B devices have a strong current driving capacity for COM and

ROW I/Os, more associated parameters are described below. VDD=2.4V~5.5V, Ta=25°C.

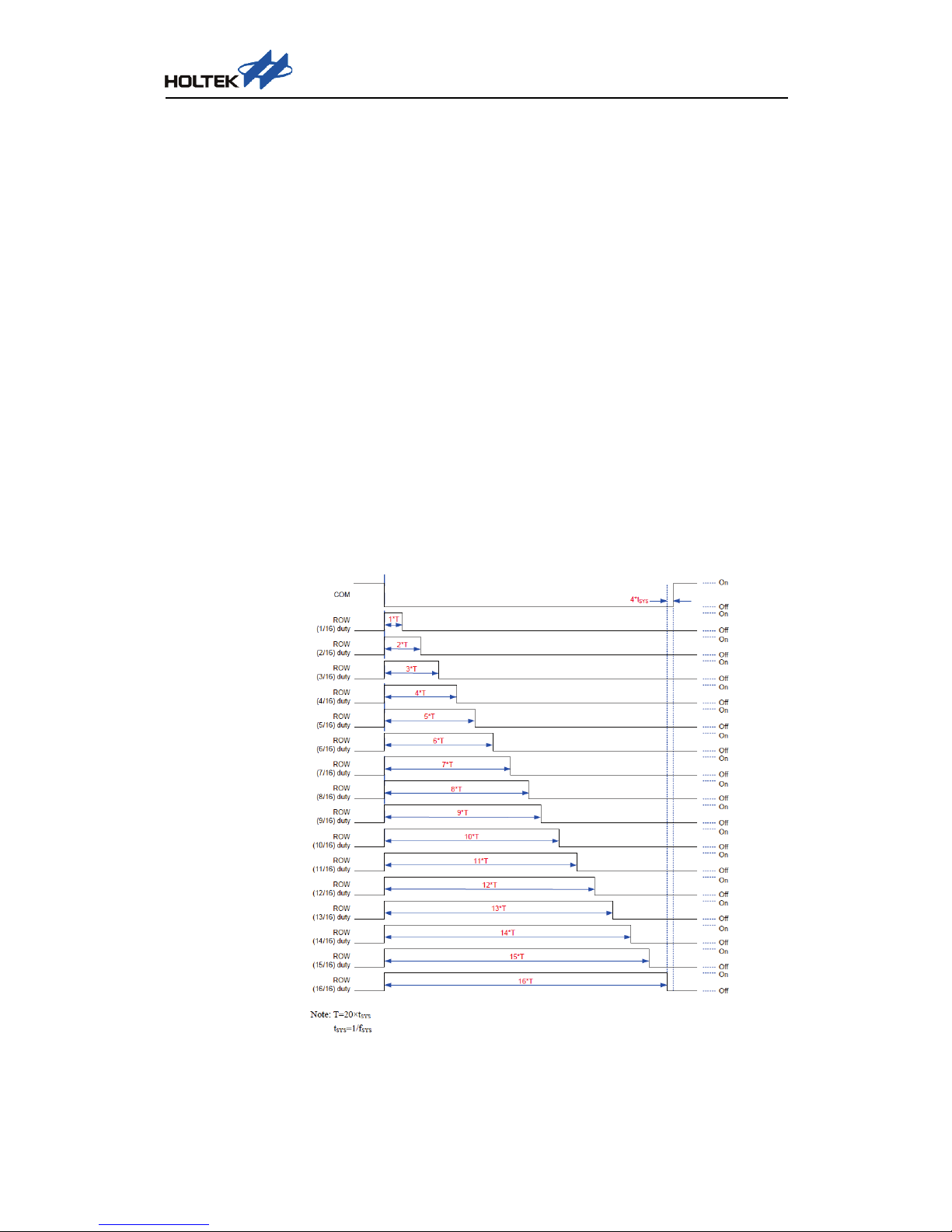

Symbol Parameter Test Conditions Min. Typ. Max. Unit

VDD Conditions

VDD Operating Voltage – – 2.4 5.0 5.5 V

IOL2 ROW Sink Current 5V VOL=0.5V 10 13 – mA

IOH2 ROW Source Current 5V VOH=4.5V -50 -70 – mA

IOL3 COM Sink Current 5V VOL=0.5V 250 400 – mA

IOH3 COM Source Current 5V VOH=4.5V -45 -60 – mA

As shown in the above table, the HT1635A/HT1635B devices support a large COM I/O

sink current with a typical value of 400mA, which coupled with the typical -70mA of ROW

I/O source current makes the devices more suitable for driving common cathode LED

matrixes. The current flowing through the LED is associated with the operating voltage

and the LED forward voltage, VF. In some applications, users can use a direct drive

method, which means LED anodes are connected to ROW I/Os and LED cathodes are

connected to COM I/Os without requiring any current limiting resistor.

It should be noted that the HT1635A/HT1635B pins LEDVDD and VDD, LEDVSS and

VSS are internally bonded together respectively, which means that driver power pins,

LEDVDD and LEDVSS, and logic power pins, VDD and VSS, are not separated.