2BTS-Series | Version 3.06

Imprint

Product identification

Belt and disc sander Item number

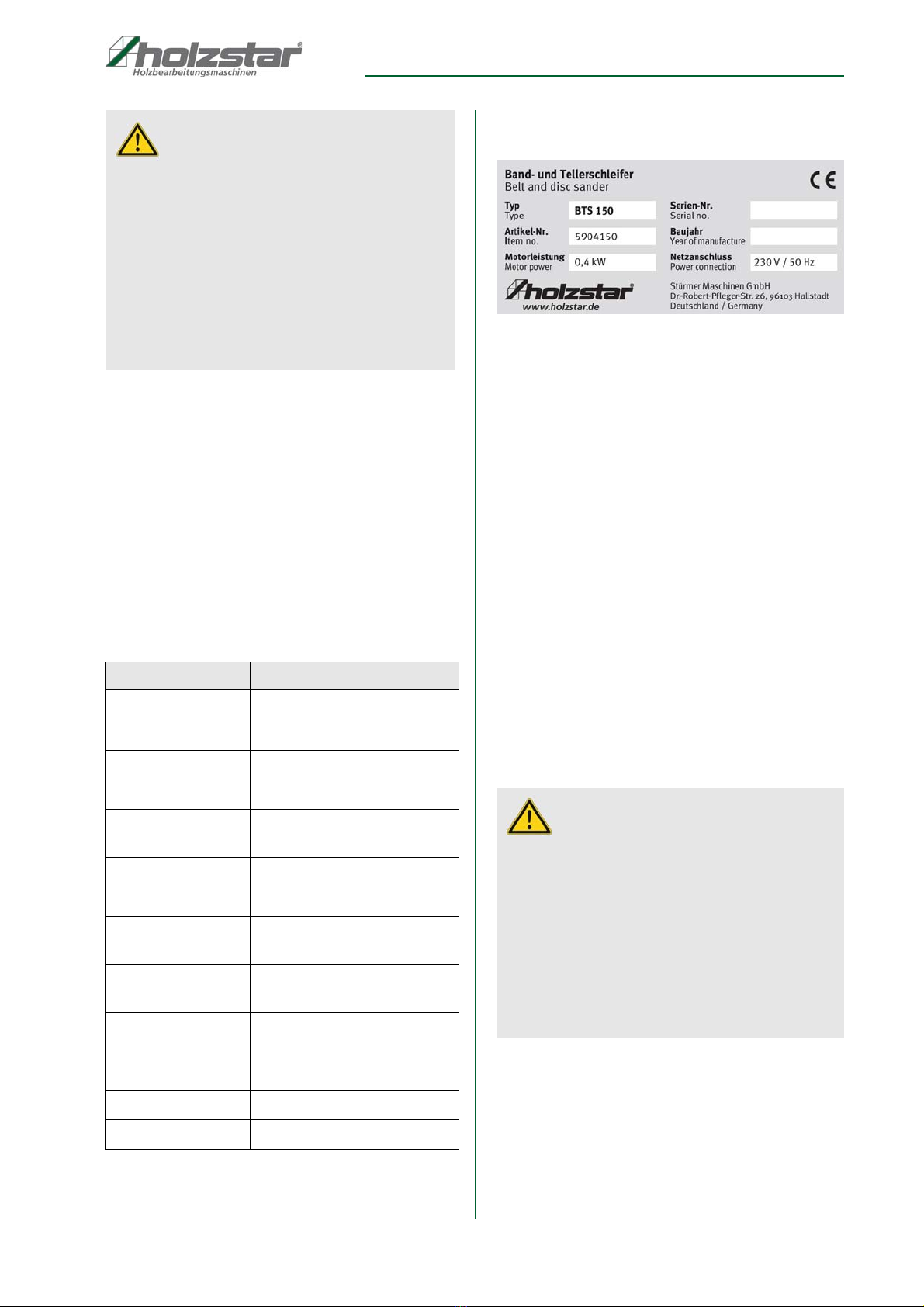

BTS 150 5904150

BTS 250 5904250

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555-55

Internet: www.holzstar.de

Indications regarding the operating instructions

Original Instruction

Edition: 04.03.2021

Version: 3.06

Language: English

Author: FL

Indications regarding the copyright

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions is the sole

property of the company Stürmer Maschinen GmbH.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Contents

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Qualification of personnel ................................... 5

2.4 Personal protective equipment ........................... 5

2.5 Safety signs on the Machine............................... 6

2.6 Regulations for safety and accident prevention.. 6

3 Intended Use ........................................... 6

4 Technical Data ....................................... 7

4.1 Type plate........................................................... 7

5 Transport, packaging, storage............... 7

5.1 Delivery and transport......................................... 7

5.2 Packaging ........................................................... 8

5.3 Storage ............................................................... 8

6 Scope of delivery and Accessories ...... 8

6.1 Scope of delivery ................................................ 8

6.2 Accessories ........................................................ 8

7 Description of the device ....................... 9

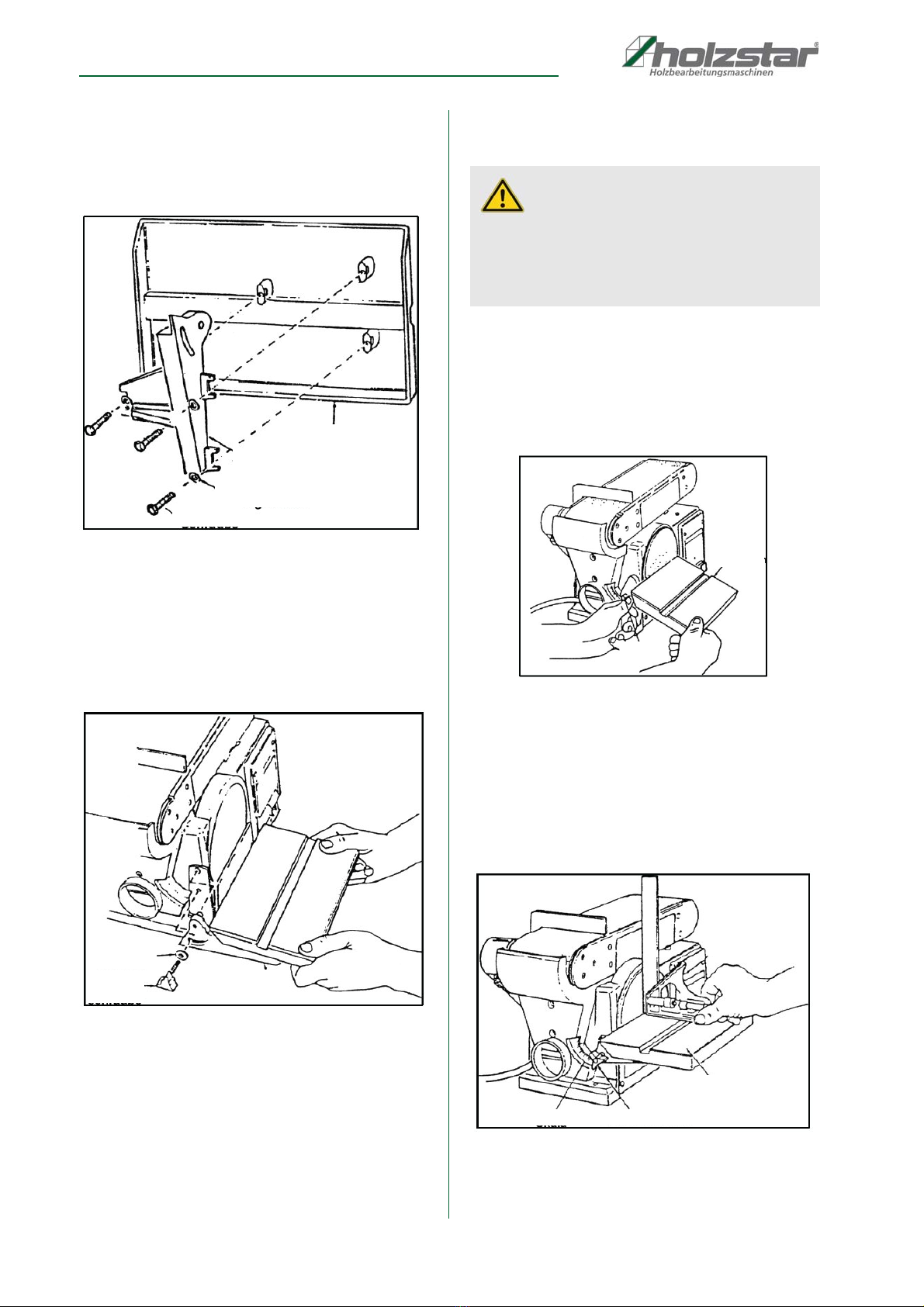

8 Assembly ................................................. 9

8.1 Safety stop.......................................................... 9

8.2 Working table.................................................... 10

9 Settings .................................................. 10

9.1 Pivoting worktable............................................. 10

9.2 Align the working table...................................... 10

9.3 Vertical grinding................................................ 11

9.4 Worktable in vertical grinding position .............. 11

9.5 Grinding wheel change ..................................... 11

9.6 Belt change....................................................... 11

9.7 Sanding belt barrel............................................ 12

10 Operation of the machine................... 12

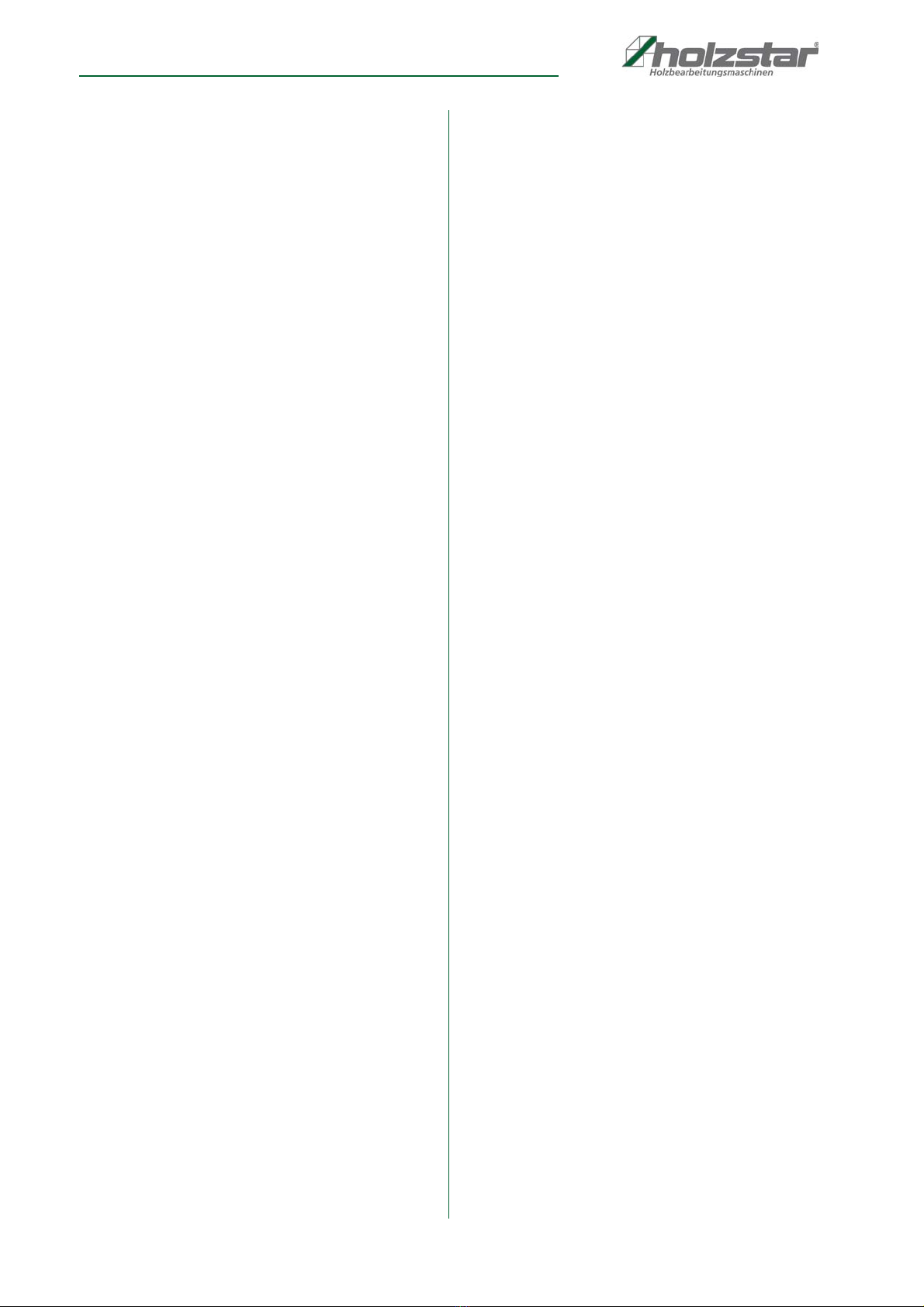

10.1 Surface grinding on the sanding belt ............. 12

10.2 Edge grinding in vertical grinding position ..... 13

10.3 Grinding bent workpieces .............................. 13

10.4 Grinding round parts on the grinding wheel... 13

10.5 Grinding ends on the grinding wheel ............ 13

10.6 Connecting piece for extraction system......... 14

11 Notes for the grinding process.......... 14

12 Care, maintenance and repair............ 14

12.1 Cleaning......................................................... 14

12.2 Maintenance .................................................. 15

13 Troubleshooting.................................. 16

14 Disposal instructions / recycling

facilities................................................ 16

14.1 Decommission ............................................... 16

14.2 Disposal of new equipment packaging .......... 16

14.3 Disposal of electrical appliances.................... 17

14.4 Disposal of lubricants..................................... 17

14.5 Disposal via municipal collection points......... 17

15 Spare parts .......................................... 17

15.1 Ordering spare parts...................................... 17

16 Spare Parts Drawings ......................... 18

16.1 Spare Parts Drawing BTS 150....................... 18

16.2 Spare parts Drawing BTS 250 ....................... 19

17 EC-Declaration of Conformity............ 20