1

CONTENTS AGE

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . .1

DOORTYPES ........................2

TOOLSREQUIRED ....................2

HARDWARE PROVIDED . . . . . . . . . . . . . . . .2

BEFOREYOUBEGIN ..................3

COMPLETED INSTALLATION . . . . . . . . . . . .3

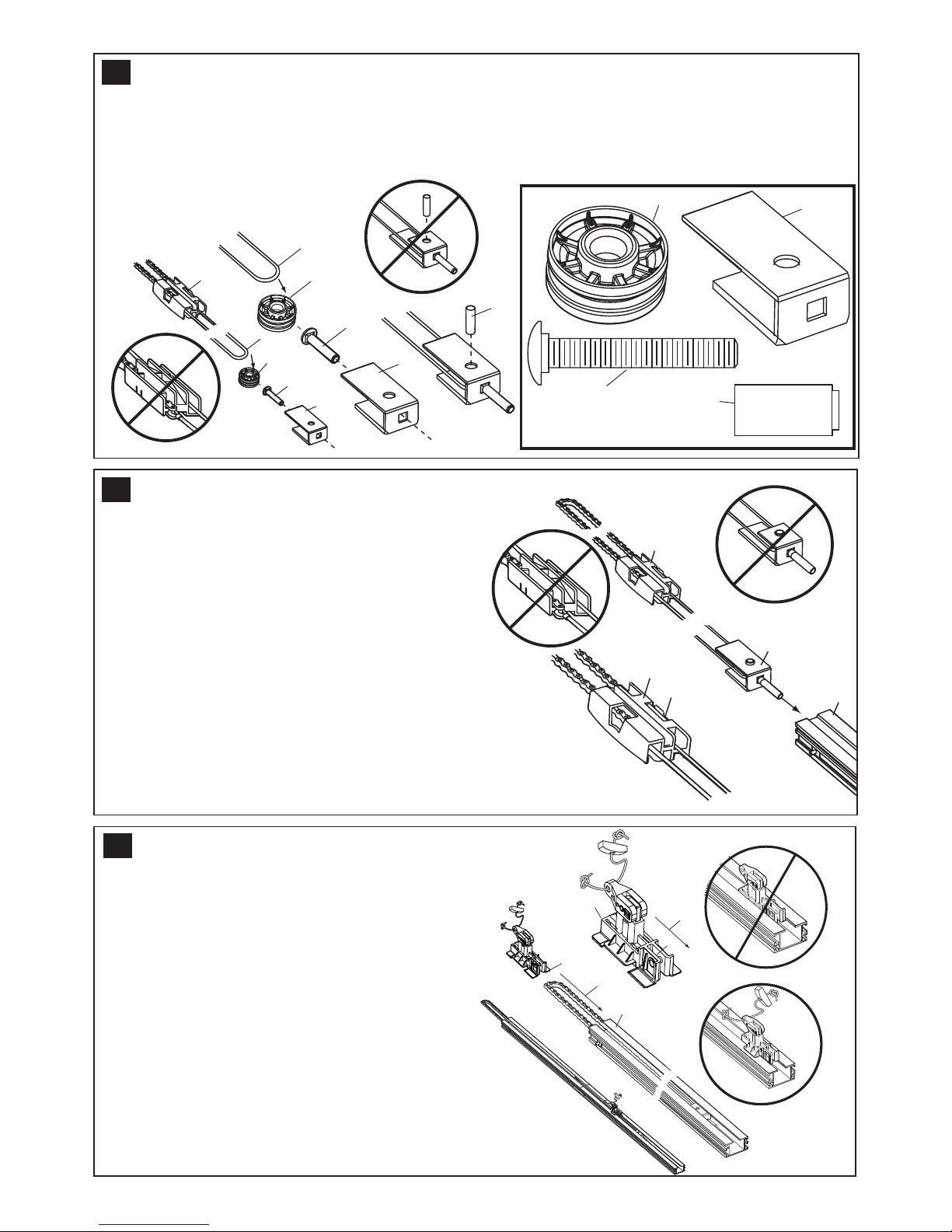

ASSEMBLY .........................3-5

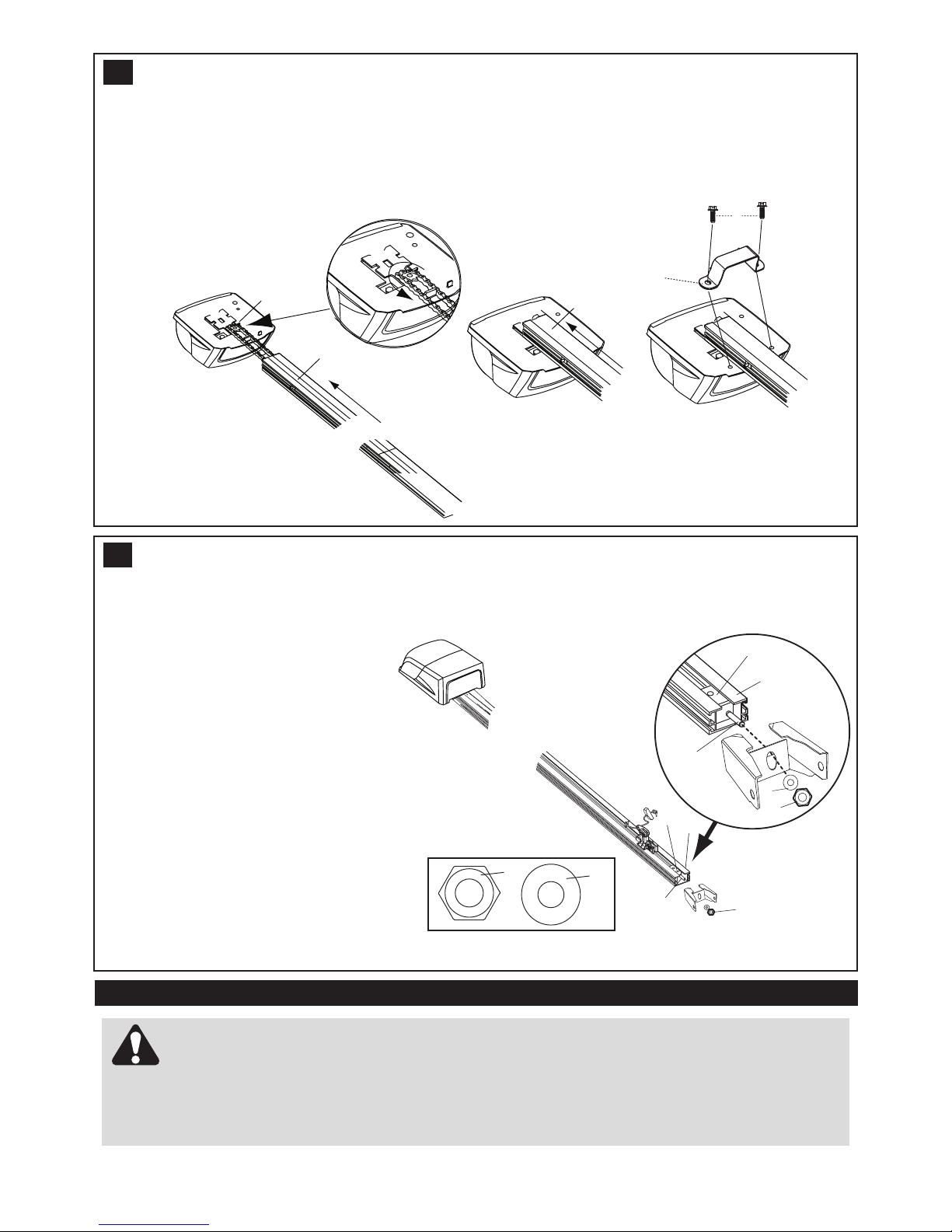

INSTALLATION ......................5-8

CONNECT ELECTRIC POWER . . . . . . . . . .8

AD USTMENT ........................9

INSTALL PROTECTOR SYSTEM . . . . . . . .10

WIRELESS PROGRAMMING . . . . . . . . .11-12

INSTALL DOOR CONTROL . . . . . . . . . . . . .13

ACCESSORIES ......................14

REPLACEMENT PARTS . . . . . . . . . . . . . . .14

OPERATION OF YOUR OPENER . . . . . . . .15

CARE OF YOUR OPENER . . . . . . . . . . . . .15

MAINTAENANCE OF YOUR OPENER . . . 15

TROUBLE SHOOTING . . . . . . . . . . . . . . . .16

SPECIFICATIONS ....................16

WARRANTY .........................17

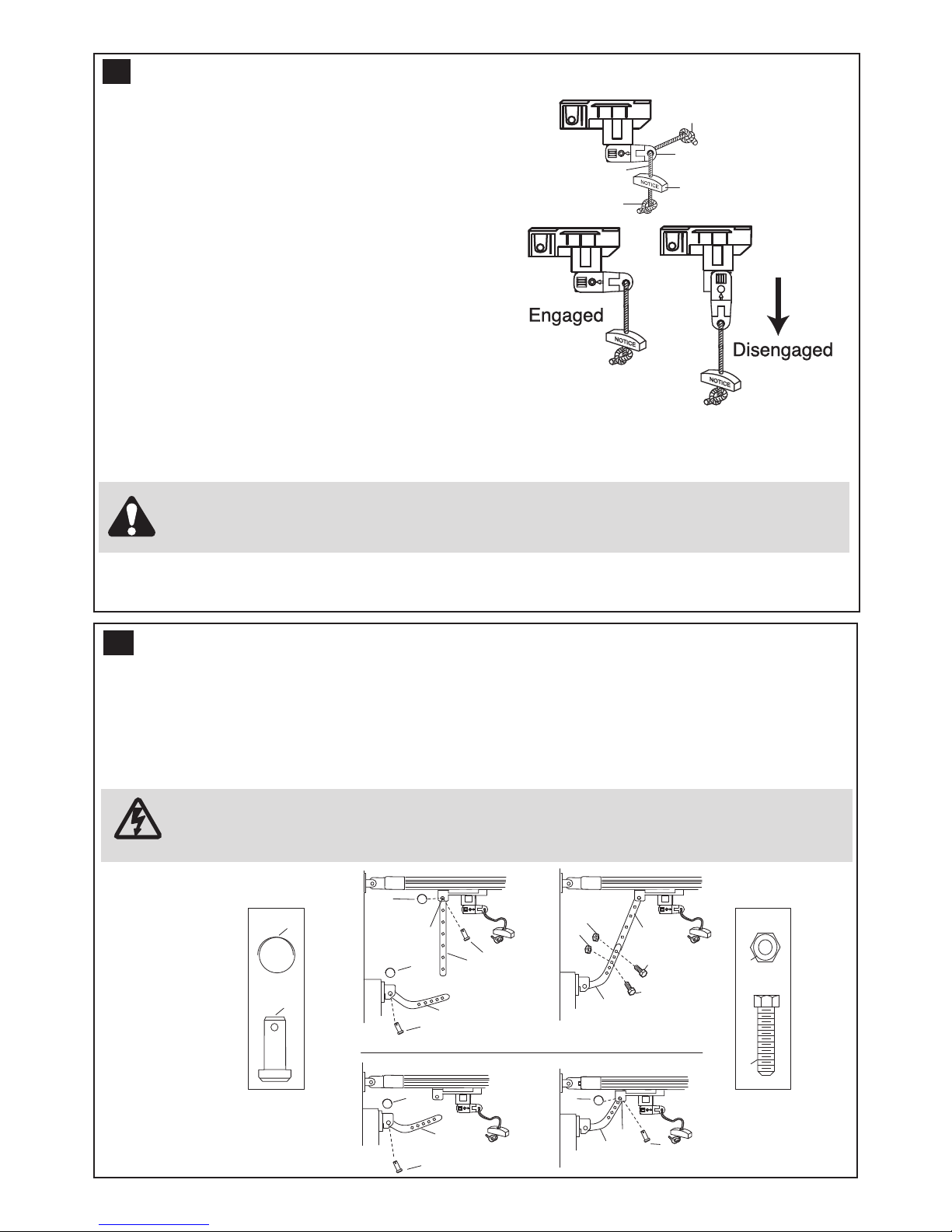

NOTE: If your garage has no service entrance door, a AML1702 outside quick release must be installed.

This accessory allows manual operation of the garage door from outside in case of power failure.

WARNING

• Failure to comply with the following instructions may result in serious personal injury or property damage.

• Read and follow all instructions carefully.

• The garage door opener is designed and tested to offer safe service provided it is installed and

operated in strict accordance with the instructions in this manual.

These safety alert symbols mean WARNING : A possible risk to personal safety or

property damage exists.

START BY READING THESE IMP RTANT SAFETY INSTRUCTI NS

The Protector SystemTM must be used for all

installations where the closing force as meas-

ured on the bottom of the door is over 400N

(40kgf). Excessive force will interfere with the prop-

er operation of the Safety Reverse System or dam-

age the garage door.

After installation, ensure that the parts of the

door do not extend over public footpaths or

roads.

Install the wireless wall control (or any additional

wall control) in a location where the garage door

is visible, at a height of at least 1.5m and out of

the reach of children. Do not allow children to

operate push button(s) or transmitter(s). Serious

personal injury from a closing garage door may

result from misuse of the opener.

Permanently fasten the Warning Labels in

Prominent Places, adjacent to Wall Controls and

manual release mechanisms as a reminder of safe

operating procedures.

Activate opener only when the door is in full

view, free of obstructions and the opener is

properly adjusted. No one should enter or leave

the garage while the door is in motion.

Do not allow children to play near the door, or

door controls.

Disconnect electric power to the garage door

opener before making repairs or removing cov-

ers.

KEEP THESE INSTRUCTI NS

Keep garage door balanced.Do not let the

garage door opener compensate for a binding or

sticking garage door. Sticking, binding or unbal-

anced doors must be repaired before installing this

opener.

Do not wear rings, watches or loose clothing

while installing or servicing a garage door opener.

Frequently examine the door installation, in par-

ticular cable, springs and mountings for signs of

wear, damage or imbalance. Do not use if repair or

adjustment is needed since springs and hardware

are under extreme tension and a fault can cause

serious personal injury.

To avoid serious personal injury from entangle-

ment, remove all ropes, chains and locks con-

nected to the garage door before installing the

door opener.

Installation and wiring must be in compliance with

your local building and electrical codes.

The safety reverse system test is very impor-

tant. Your garage door MUST reverse on contact

with a 40mm obstacle placed on the floor. Failure to

properly adjust the opener may result in serious

personal injury from a closing garage door. Repeat

the test once a month and make any necessary

adjustments.

This opener should not be installed in a damp

or wet space exposed to weather.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervi-

sion or instruction concerning use of the appliance

by a person responsible for their safety.