HOMMY ENTERPRISE (XINHUI) CO., LTD.

http://www.hommy.com 5-32

MATTERS NEEDING ATTENTION

●Matters needing attention before using ice cream machine:

1. The machine is subject to shocks in the transport process, the best first place 24 hours before use.

2. Different machine has different ability to adapt to different types of environmental temperature, and

must be avoid direct sunlight and away from the heat source.

3. The material temperature after pouring into the hopper is suggested to cool down to 2℃-4℃before

making ice cream, so conducive to the material preservation and the taste improvement.

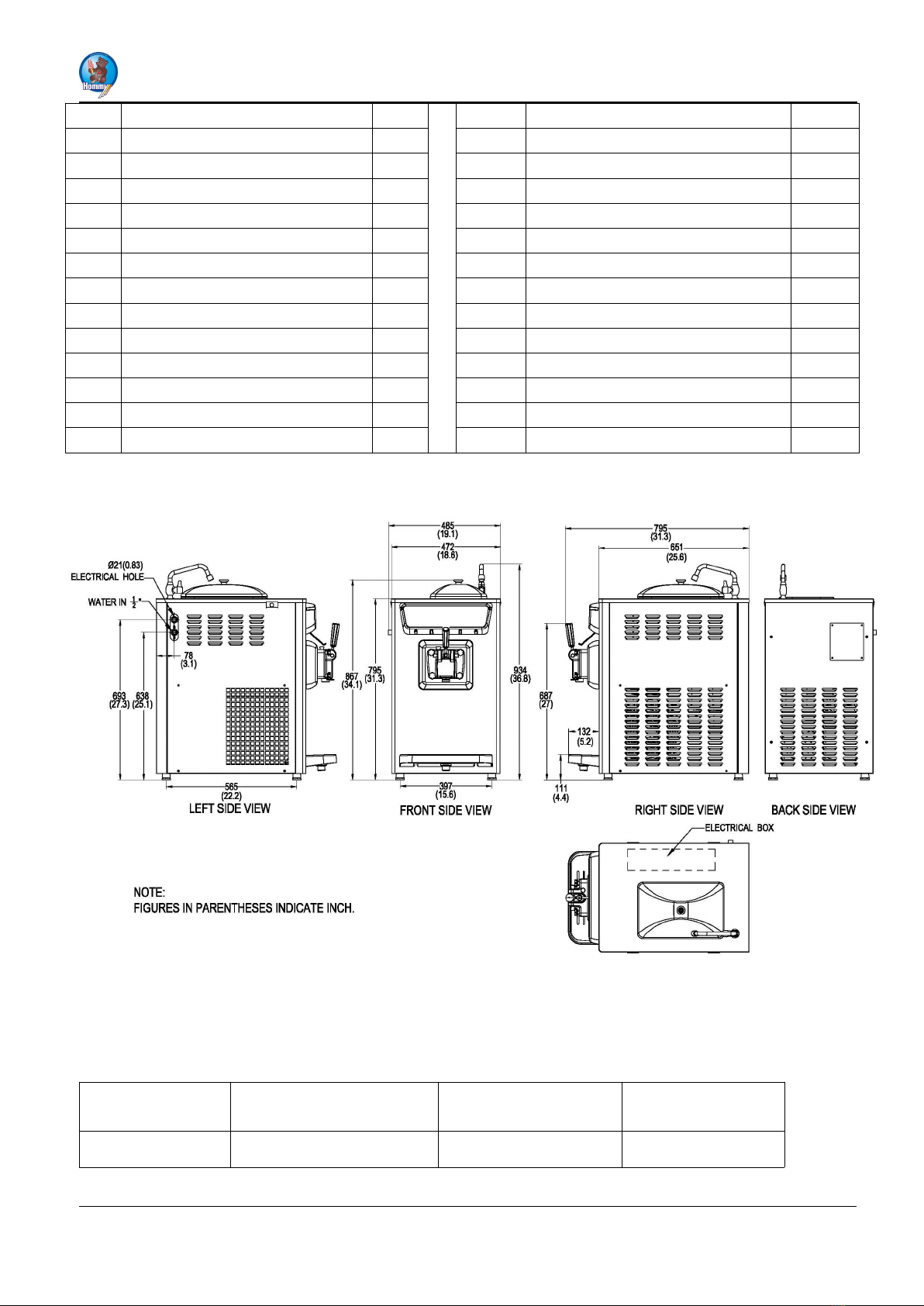

4. The machine should choose a place with good ventilation, and place on a level surface..

5. The rotation direction of the stirring shaft should be in clockwise.

6. The air inlet on the machine (left / right / rear plate) must keep with good ventilation.

7. The dust on the condenser to be cleaned regularly, the best cleaning once every month.

8. Matters needing attention for air-cooled machine: There are 50 cm above the space in which air flows

into the machine should be on the side of machine, the bottom of the machine can not have other objects

block, in order to ensure the machine cooling.

9. When the freezing cylinder has no material or lack of material, the machine can not enter the

refrigeration function.

10. The machine is not used for a long time, please unplug the power line or the external power switch off.

●Matters needing attention for the power line:

a) Machine shell must be grounded.

b) When the use of a supply voltage is 200V~240V, the cross-sectional area is not less than 4mm2 power

line, to ensure that the current adequacy. Because of the large starting current, so the total capacity of

outside power supply line load power requirements.

c) When the use of three-phase is 380V/50HZ power supply, the cross-sectional area is not less than

2.5mm2 power line, to ensure that the current adequacy. Because of the large starting current, so the

total capacity of outside power supply line.