3

Honeywell Titan SCBA, 20132

WARNING—CONTINUED

• ONLY grasp the cylinder valve handwheel

to open or close the valve. DO NOT pick up

or carry a cylinder by the handwheel, drop

a cylinder on the handwheel, or bump the

handwheel, as this may cause the cylinder

valve to inadvertently open, which may lead

to the cylinder becoming airborne under the

thrust of air released from the open valve,

causing injury or death. ALWAYS pick up

and carry an air cylinder by the cylinder

body.

• Do not over-torque air cylinder valves.

ALWAYS verify that the hydrostatic test

facility performing your cylinder testing

DOES NOT over-torque the cylinder valves

when they reinstall them.

• Some CBRN agents may not present

immediate effects from exposure, but can

result in delayed impairment, illness, or

death.

• Direct contact with CBRN agents requires

proper handling of the SCBA after each use

and between multiple entries during the

same use.

• Decontamination and disposal procedures

must be followed. If contaminated with

liquid chemical warfare agents, dispose of

the SCBA after decontamination.

• The respirator should not be used

beyond six (6) hours after initial exposure

to chemical warfare agents to avoid the

possibility of agent permeation.

• Prior to using the Titan SCBA for the

fi rst time, you must perform fi t testing as

described in section VI. Do not wear this

respirator if a satisfactory fi t, as determined

by the fi t testing described in section VI,

cannot be obtained.

• You must read, understand, and follow all

warnings, instructions, labels, and Safety

Data Sheets (SDS), etc., for the materials

you are using (e.g., paints, hardeners,

insecticides, varnishes, etc.).

• You must also read, understand, and follow

all warnings, instructions, etc., listed in the

SDS for any contaminants that may be or

are present in the work area.

• FAILURE TO COMPLY WITH THESE

WARNINGS MAY RESULT IN PERSONAL

INJURY, ILLNESS, OR DEATH.

WARNING

Detectable amounts of chemicals known

to the State of California to cause cancer,

birth defects, or reproductive harm may

be found in this product. (This warning

required by California Health and Safety

Code Section 25249.6)

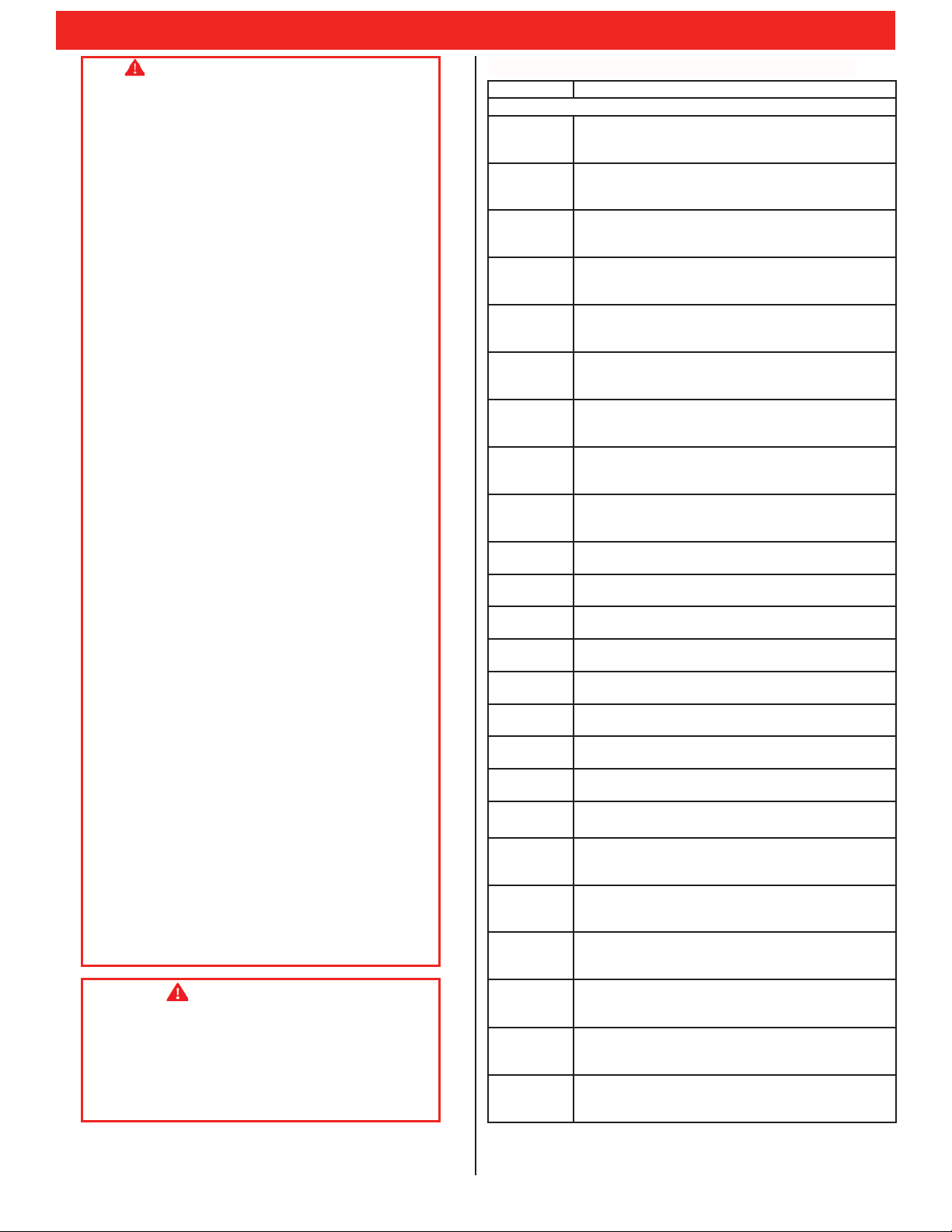

Part No. Description

FACEPIECES

282053 FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, SMALL BLACK NOSE CUP, SILICONE

HEADSTRAP

282012 FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, MEDIUM BLACK NOSE CUP, SILICONE

HEADSTRAP

282013 FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, LARGE BLACK NOSE CUP, SILICONE

HEADSTRAP

282041 FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, SMALL BLACK NOSE CUP, SILICONE

HEADSTRAP

282022 FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, MEDIUM BLACK NOSE CUP, SILICONE

HEADSTRAP

282023 FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, LARGE BLACK NOSE CUP, SILICONE

HEADSTRAP

282043 FACEPIECE—TWENTY/20+, CBRN, LARGE,

BLACK, SMALL BLACK NOSE CUP, SILICONE

HEADSTRAP

282032 FACEPIECE—TWENTY/20+, CBRN, LARGE,

BLACK, MEDIUM BLACK NOSE CUP, SILICONE

HEADSTRAP

282033 FACEPIECE—TWENTY/20+, CBRN, LARGE,

BLACK, LARGE BLACK NOSE CUP, SILICONE

HEADSTRAP

282048 FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, SMALL BLACK NOSE CUP, HEADNET

282016 FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, MEDIUM BLACK NOSE CUP, HEADNET

282017 FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, LARGE BLACK NOSE CUP, HEADNET

282050 FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, SMALL BLACK NOSE CUP, HEADNET

282026 FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, MEDIUM BLACK NOSE CUP, HEADNET

282027 FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, LARGE BLACK NOSE CUP, HEADNET

282052 FACEPIECE—TWENTY/20+, CBRN, LARGE,

BLACK, SMALL BLACK NOSE CUP, HEADNET

282036 FACEPIECE—TWENTY/20+, CBRN, LARGE,

BLACK, MEDIUM BLACK NOSE CUP, HEADNET

282037 FACEPIECE—TWENTY/20+, CBRN, LARGE,

BLACK, LARGE BLACK NOSE CUP, HEADNET

282053T FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, SMALL BLACK NOSE CUP, W/TEMPLE

INSERTS, SILICONE HEADSTRAP

282012T FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, MEDIUM BLACK NOSE CUP, W/TEMPLE

INSERTS, SILICONE HEADSTRAP

282013T FACEPIECE—TWENTY/20+, CBRN, SMALL,

BLACK, LRG BLACK NOSE CUP, W/TEMPLE

INSERTS, SILICONE HEADSTRAP

III. PARTS LIST

282041T FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, SMALL BLACK NOSE CUP, W/TEMPLE

INSERTS, SILICONE HEADSTRAP

282022T FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, MEDIUM BLACK NOSE CUP, W/TEMPLE

INSERTS, SILICONE HEADSTRAP

282023T FACEPIECE—TWENTY/20+, CBRN, MEDIUM,

BLACK, LARGE BLACK NOSE CUP, W/TEMPLE

INSERTS, SILICONE HEADSTRAP