TRUEZONE ARD, EARD, AND ZD SERIES DAMPERS

333-00040—01

Installing the Round (ARD and

EARD) Dampers

1. Insert the crimped end of the ARD or EARD into the

uncrimped end of the rigid round duct and secure with

sheet metal screws (not provided). When using flexible

duct, slip the duct over the end of the ARD or EARD and

secure it with duct straps (not provided).

2. When installing the damper in a horizontal application,

make sure the motor actuator is located on the side or

top of the damper. Do not locate the motor on the bot-

tom of the damper. The damper can be mounted in a

vertical duct.

3. Adjust Range stop position to desired closed positions.

ARD and ZD Dampers are completely closed in position

0. EARD Dampers are completely open in position 0.

Fig. 2. TrueZONE Actuator range stop positions.

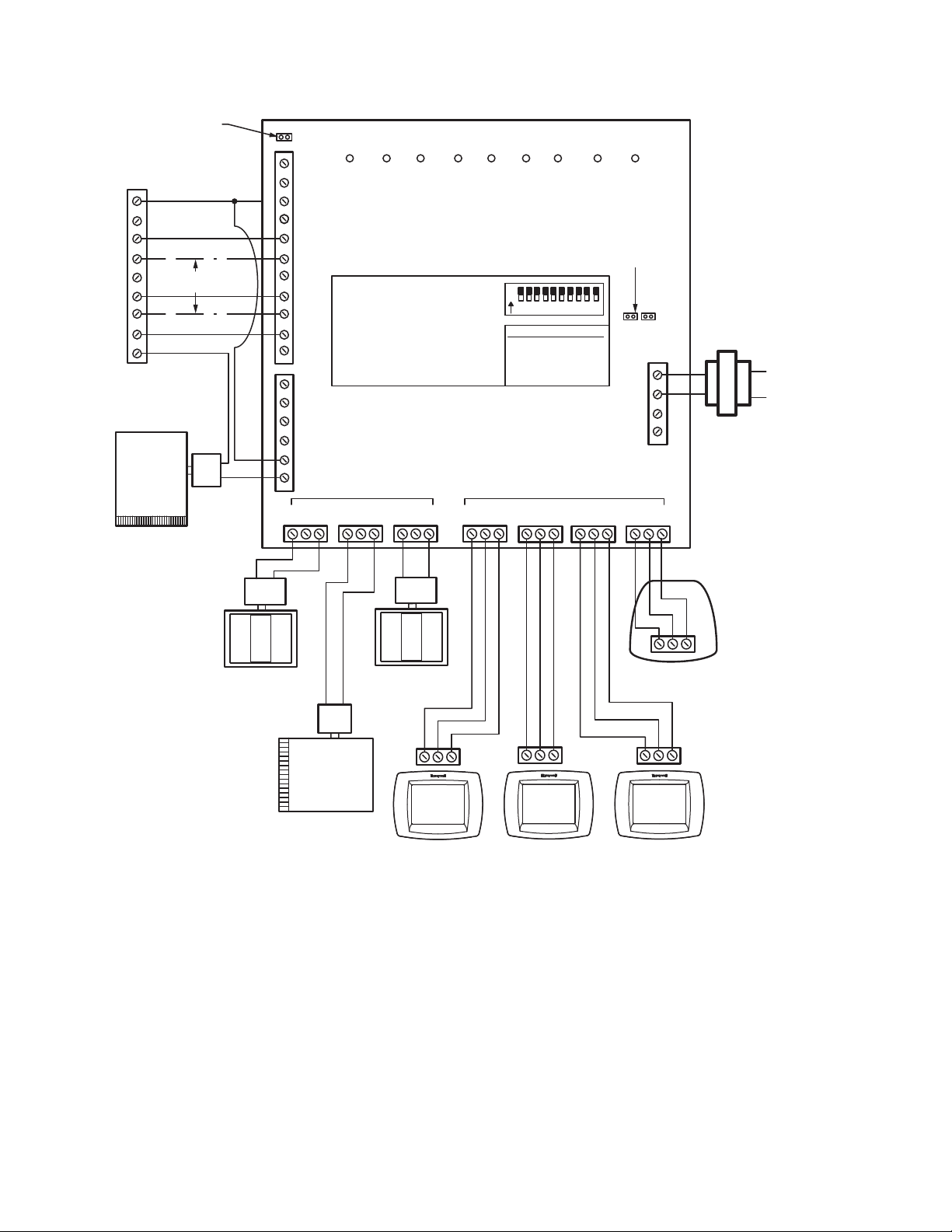

Wiring Multiple Dampers

When the same zone controls two or more dampers, wire the

dampers in parallel to terminals M1 and M6 on the zone

control panel.

INSTALLATION OF ZD DAMPER

When Installing this Product…

1. Read these instructions carefully. Failure to follow these

instructions can damage the product or cause a hazard-

ous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service techni-

cian.

4. All wiring must comply with local electrical codes, ordi-

nances, and regulations.

5. After completing installation, use these instructions to

check out the product operation.

Planning the Installation

Selecting a Location

Select a location for the zone dampers that is at least three

feet from the HVAC unit plenum in the air duct takeoff to the

respective zone and is easily accessible for checkout and

maintenance.

The ZD comes complete and ready for installation. The motor

and linkage are factory-assembled to the damper. The

damper is assembled for installation and wiring to the control

panel.

Selecting Damper Size

To ensure correct operation, be sure to select the correct zone

damper size for the air duct:

IMPORTANT

Be aware that damper sizes are built 5/32 in. smaller

than the listed dimensional sizes.

• If the damper is forced into an undersized air duct, the

excess pressure can jam the damper blades and cause

improper operation.

• When a small percentage of continuous flow is desired in a

zone, even when the damper blades are closed, adjust

motor closed position to be slightly open to maintain

desired air flow.

Selecting Location with Humidifier

Installed

IMPORTANT

Excessive lime or mineral deposits can accumulate

on damper blades and cause improper operation

when spray or atomizing type humidifiers are

installed in the furnace plenum or air supply duct with

the zone dampers.

• Spray or atomizer type humidifiers that are installed in the

furnace plenum or air supply duct are not recommended.

• Evaporative type humidifiers are recommended.

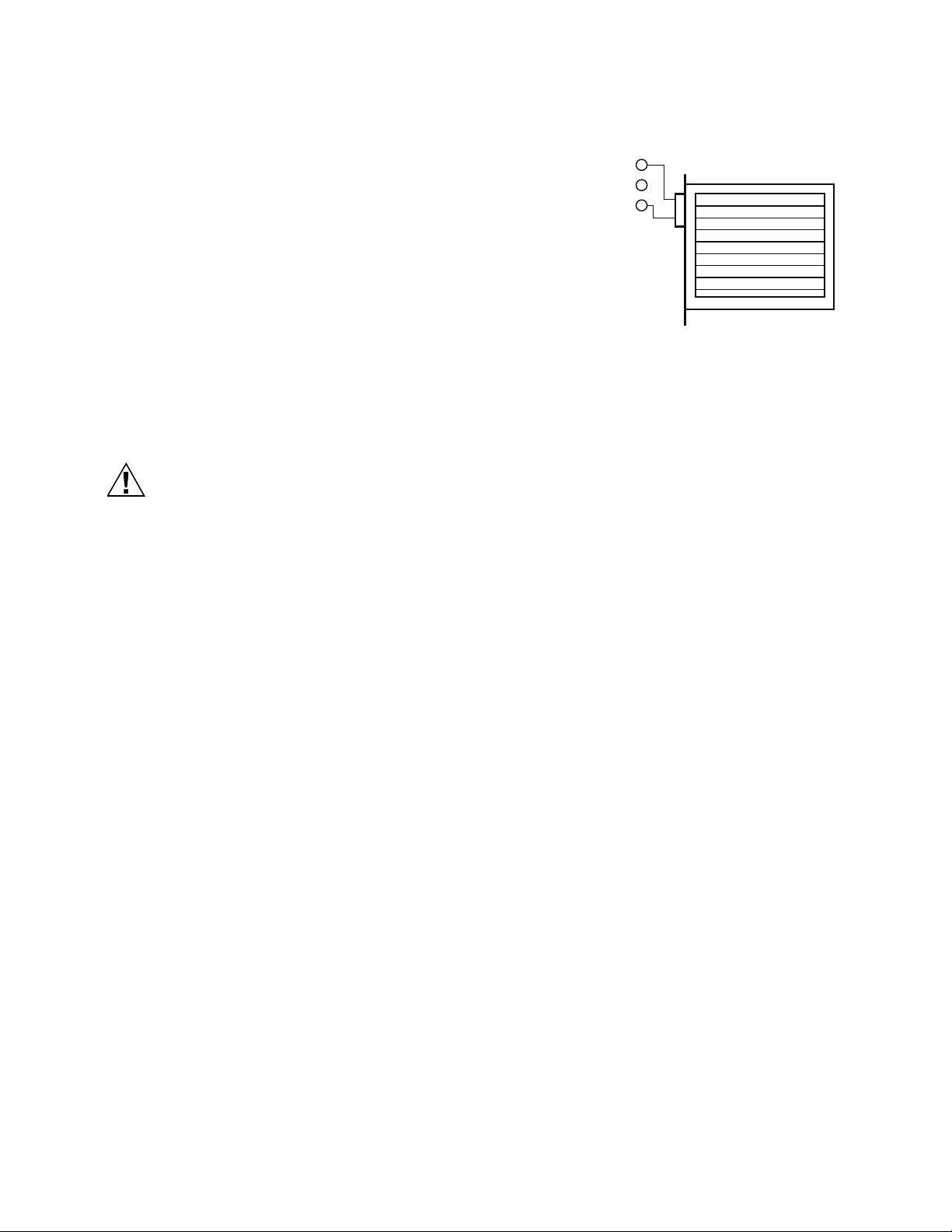

Installing the Damper

IMPORTANT

— Install dampers into a squared air duct.

— Do not weld dampers to the air ducts.

— Do not force dampers into undersized air ducts.

Excess pressure can damage damper blades.

— Be sure high limit setting is less than 200° F (93°C).

— Higher settings can damage the electric actuator.

1. Be sure the ZD is correctly sized to the air duct (see

Selecting Damper Size section).

2. Select a ZD location that is three feet from the furnace

plenum.

3. Cut a 4-in. (102 mm) opening in the accessible side of

the air duct at the location selected; ensure the opening

of the air duct is cut fully from seam to seam.

4. Secure the ZD mounting plate to the air duct with the

self-tapping sheet metal screws provided.

M35187

RANGE STOP

LOCATIONS