Hoover SteamVac F5835-900 Operating instructions

Other Hoover Vacuum Cleaner manuals

Hoover

Hoover HandVac User manual

Hoover

Hoover HSV600C Installation guide

Hoover

Hoover SH40080 User manual

Hoover

Hoover FH50 User manual

Hoover

Hoover FD22G User manual

Hoover

Hoover Synua Plus SY51 User manual

Hoover

Hoover HGO320H 011 User manual

Hoover

Hoover ROYAL User manual

Hoover

Hoover Freejet User manual

Hoover

Hoover SM156DPN User manual

Hoover

Hoover Floormate FL700 User manual

Hoover

Hoover Rogue 970 User manual

Hoover

Hoover ONEPWR Blade+ User manual

Hoover

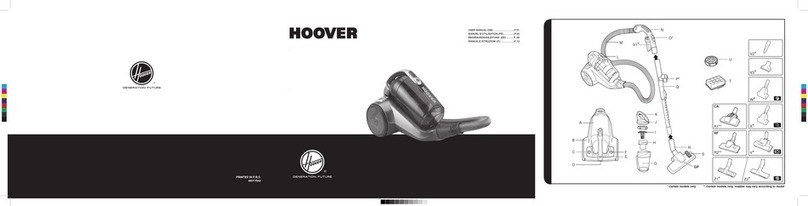

Hoover VAPORLITE User manual

Hoover

Hoover VAPORLITE PRO User manual

Hoover

Hoover Tranquility User manual

Hoover

Hoover CL-EVERYDAY Series User manual

Hoover

Hoover 5014 pets User manual

Hoover

Hoover MAXLIFE TOTAL HOME PET User manual

Hoover

Hoover RC71 User manual