AN191

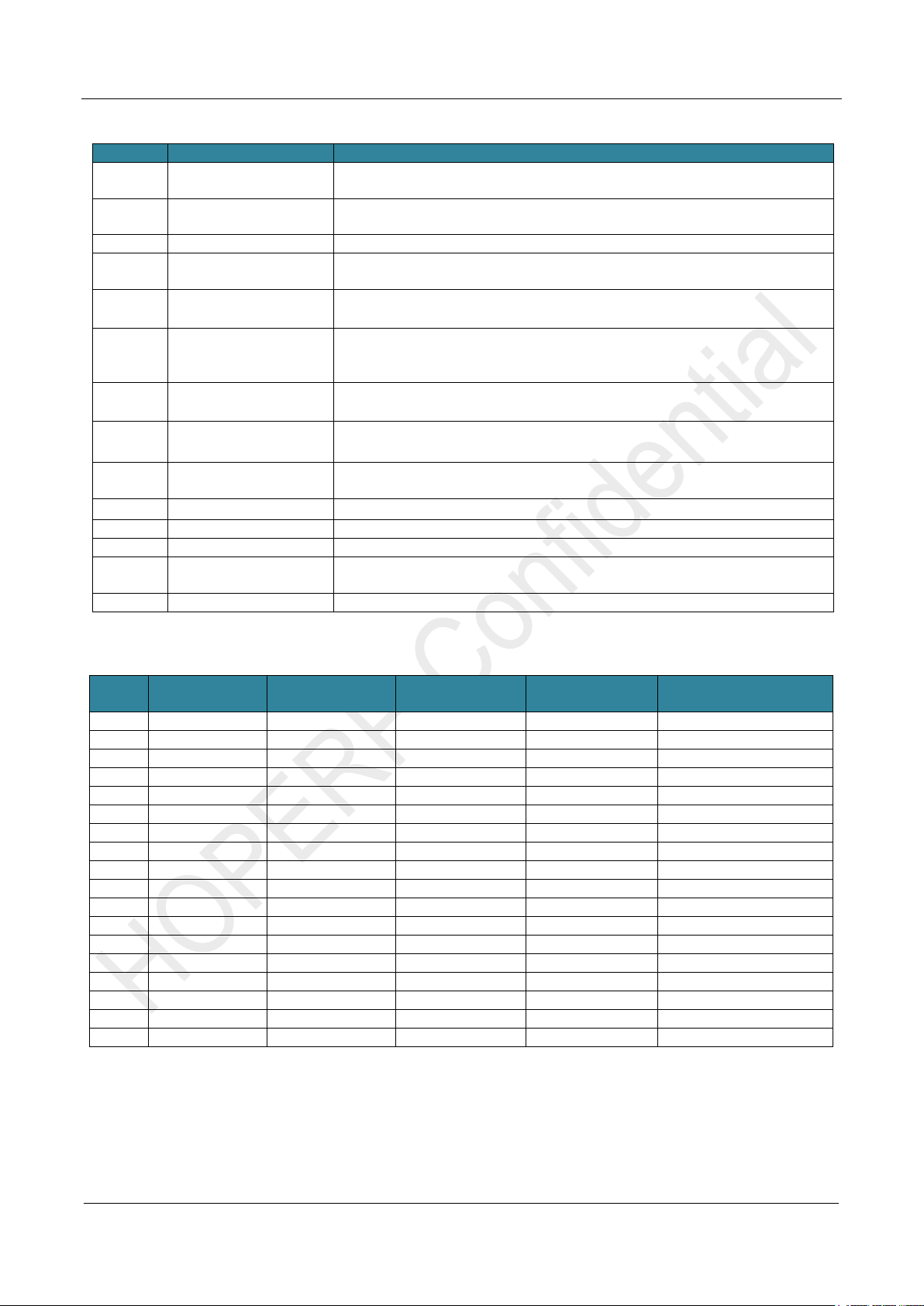

Table of Contents

1Hardware Platform....................................................................................................................................4

1.1 CMT2380F64-EB Introduction.......................................................................................................... 4

1.2 CMT2380F64-QFN48-EB Introduction............................................................................................. 6

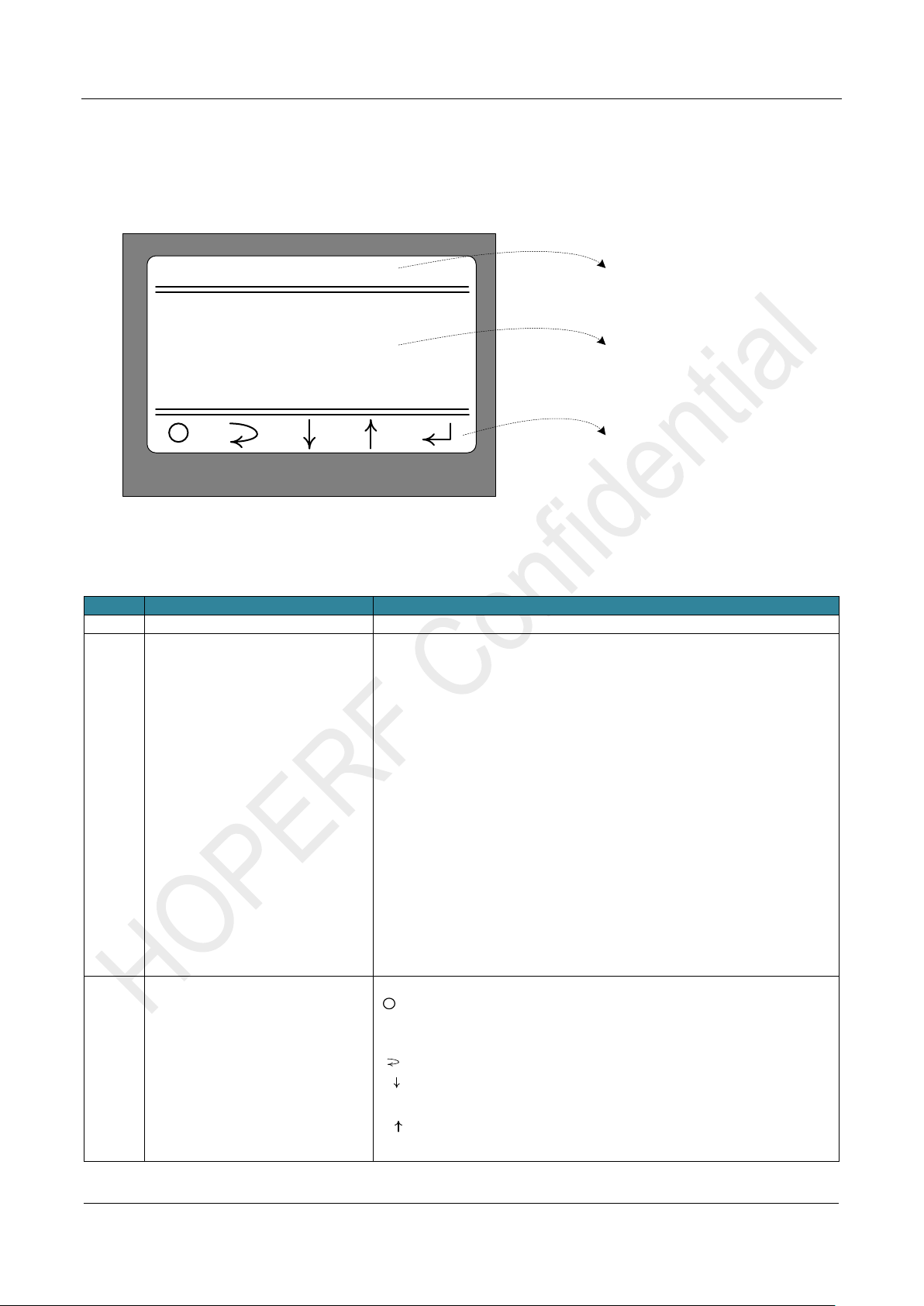

1.3 LCD Shiled Introduction.................................................................................................................... 8

2Introduction for Parameter Setting.........................................................................................................9

2.1 Startup Interface............................................................................................................................... 9

2.2 Main Menu Interface....................................................................................................................... 10

2.3 Modulation Submenu.......................................................................................................................11

2.4 Work Mode Submenu......................................................................................................................11

2.5 Frequencry Band Submenu............................................................................................................ 13

2.6 Data Rate Submenu....................................................................................................................... 13

2.7 Tx Output Power Submenu ............................................................................................................ 14

2.8 Preamble Length Submenu............................................................................................................ 15

2.9 Packet Length Submenu ................................................................................................................ 16

2.10 Coding Format Submenu ............................................................................................................... 17

2.11 CRC Select Submenu .................................................................................................................... 18

2.12 CRC Seed Value Submenu........................................................................................................... 18

2.13 CRC Result Inv Submenu .............................................................................................................. 19

2.14 Packet Structure............................................................................................................................. 19

2.15 Frequencry Space and Frequencry Channel Submenu................................................................. 20

2.16 Gaussian Select Submenu............................................................................................................. 21

2.17 Test Counter Submenu................................................................................................................... 22

2.18 Payload Content Submenu............................................................................................................. 24

2.19 AFC Select Submenu..................................................................................................................... 24

2.20 Dout Disable Submenu................................................................................................................... 25

2.21 Interval Select Submenu ................................................................................................................ 25

3Working Mode Description ................................................................................................................... 26

3.1 Sleep Mode..................................................................................................................................... 26

3.2 CW Tx Mode................................................................................................................................... 28

3.3 Direct Rx Mode............................................................................................................................... 30

3.4 Only Tx Mode ................................................................................................................................. 31

3.5 Only Rx Mode................................................................................................................................. 33

3.6 Tx and Rx Mode ............................................................................................................................. 34

4Supplymentary....................................................................................................................................... 37