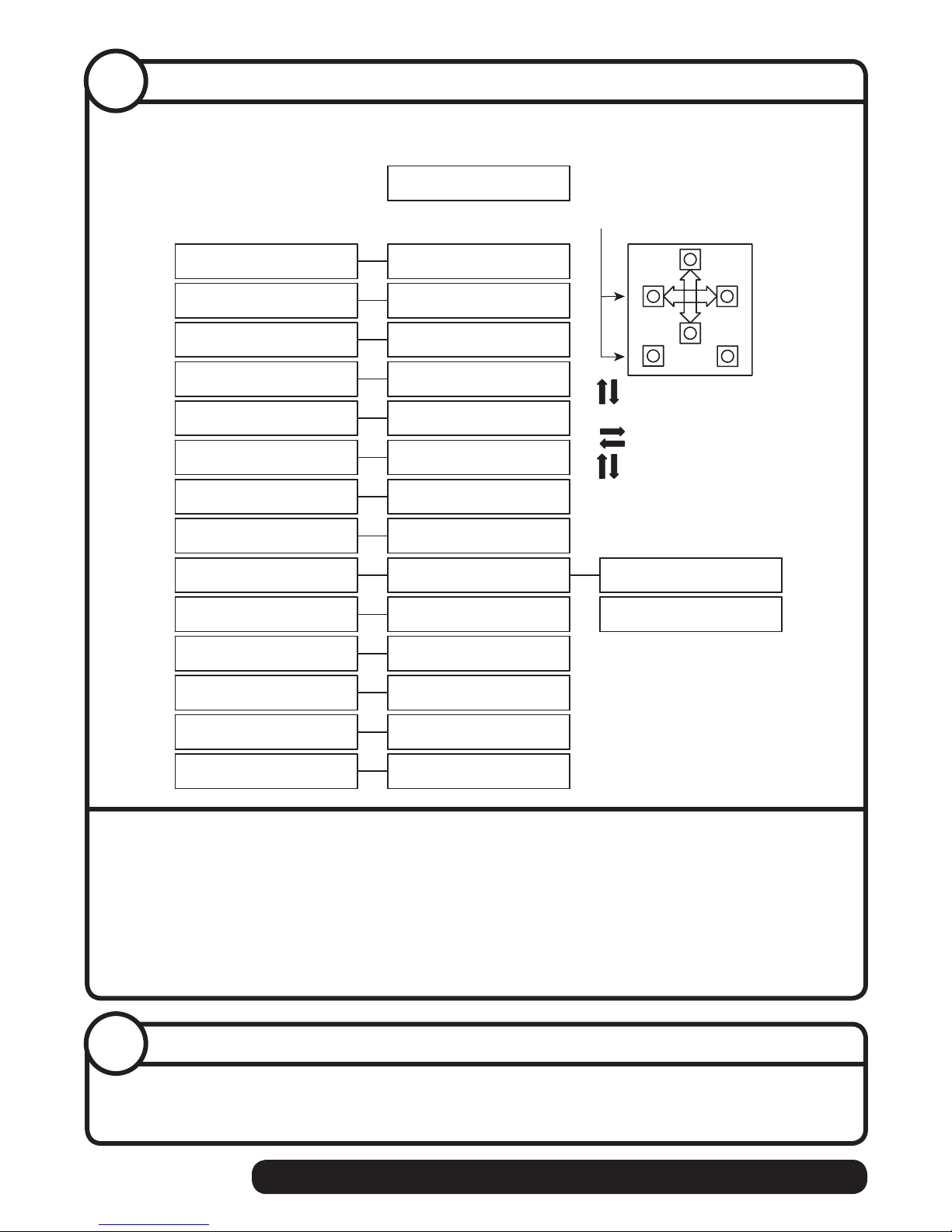

5

HARMONY and Symphony Plus • RIDE Technology self-contained

➍

H_C1400A/W

H_C1000A/W

NEMA

6-20

NEMA

6-15

➋➌

➊

➍

H_E1000A/W‡

1' (0,3m)

1/4" (6,4mm)

H_E1400A/W‡

requires 15A circuit,

1.50 mm2wire

requires 20A circuit,

4.00 mm2wire

Prepare the installation site. 2

Site preparation

Electrical ➊

• H_C1000(A/W)HS 208-230/60/1-15 amps • H_C1400(A/W)HS 208-230/60/1-20 amps

• H_E1000(A/W)HS 230/50/1-15 amps‡• H_E1400(A/W)HS 230/50/1-20 amps‡

(H_E1000A/W requires 15A circuit, 1.50 mm2wire) (H_E1400A/W requires 20A circuit, 4.00 mm2wire)

‡ Plug must be provided by end user & must conform to standard EN 60 335-2-24 of the end destination.

Potable water supply ➋

• 10-70 psi (69-483kpa)

• 45 to 90 F (7 to 32 C)

• Follett recommends the use of an in-line water ltration system (#00130286)

Condenser water supply for water-cooled systems ➌

• 10 psi min.; 150 psi max. (69kpa min.; 1034kpa max.)

• 45 to 90 F (7 to 32 C)

• 1.5 gallons per minute (5.68 liters per minute)

Drain ➍

• The drain line from the ice machine must have at least 1/4" per foot pitch (6,4mm/0,3m)

2.1

Provide drainage, water supply and electrical power to within 6 feet (2m)

of ice machine in accordance with local and national codes. Outdoor

installation is not recommended and will void warranty.

Installation site requirements

2.1