Horstmann ComPass B User manual

4023841-001

June 2011

Instructions for Use

ComPass B

100104-0426 Translation of the German version

Dipl.-Ing. H. Horstmann GmbH

Humboldtstraße 2

42579 Heiligenhaus

www.horstmanngmbh.com

Instructions for Use

ComPass B 4023841-001

2

Dipl.-Ing. H. Horstmann GmbH

Contents

Intended Use1. 4

Description of supply2. 4

Scope of delivery2.1. 4

Display Unit2.2. 4

Current transformers2.3. 4

WEGA 1.2 C and WEGA 2.2 C2.4. 5

HR-interface cable set2.5. 5

Capacitive insulators2.6. 6

Device functions3. 6

Fault detection and fault indication3.1. 6

Fault detection3.1.1. 6

Fault direction3.1.2. 7

Voltage ring buffer3.1.3. 8

Inrush current suppression3.1.4. 8

Fault indication3.1.5. 8

Reset modes3.1.6. 9

Measuring the values in a medium-voltage system 13.2. 0

Operator control 13.3. 0

Front panel 13.3.1. 0

RS485/MODBUS interface 13.3.2. 1

Digital inputs/outputs 13.3.3. 1

Power Supply 13.4. 1

Test mode 13.5. 2

Installation 14. 2

Safty instructions 14.1. 2

Plug-in housing for panel mount 14.2. 2

Installation of current transformers 14.3. 2

General 14.3.1. 2

Installation of single-phase current transformers 14.3.2. 3

Installation of summation current transformers 14.3.3. 3

Electrical connection 14.4. 4

Terminal strips 14.4.1. 4

Assignment of terminal strips 14.4.2. 4

Device conguration and commissioning 15. 5

Device configuration 15.1. 5

Voltage calibration 15.2. 6

Commissioning 15.3. 8

Technical Data 16. 8

Appendix A: Parametrization ComPass B 19-23

Appendix B: Menu Conguration ComPass B 24-29

Instructions for Use

ComPass B 4023841-001

General Information!

Before installing and operating this instrument carefully read and understand the contents of this

manual.

The content of this operating manual reects the current state of the art at the date of printing. We

reserve the right to make technical changes at any time and without prior notice as necessary in the

framework of ongoing developments. .

Safty Note!

Installation, connection and commissioning of the device must be carried out exclusively by

a skilled/qualied electrician observing the following safety rules according to DIN VDE0105:

Make sure that the instrument is only used for the purpose for which it has been designed

as described in the present operating manual.

Abbreviations

Abbreviations Meaning

IE>Earth fault

I>> Short-circuit

IBOperating current

IEEarth fault current

IKShort-circuit current

MV Medium-voltage

CT Current transformer

V> Overcurrent

V< Undervoltage

VNE Neutral point displacement voltage

P Active power

Q Reactive power

S Apparent power

Declaration of Conformity

This instrument is in conformity with the requirements of the EC Electromagnetical Compatibility

(EMC) Directive and the EC Low Voltage (LVD) Directive in the current state of issue.

If required, the -Declaration of Conformity may be obtained from the following address:

Dipl.-Ing. H. Horstmann GmbH, Humboldtstraße 2, 42579 Heiligenhaus

3

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Intended Use1.

The ComPass B is used in medium-voltage distribution networks and combines the functions of a

directional short-circuit and directional earth fault indicator.

It has been developed and designed

to detect short-circuits and earth faults•

to indicate and remotely signal the fault direction (A or B)•

to measure, indicate and remotely signal load current, voltage, power, cos φ and frequency •

of medium-voltage networks

to monitor the load ow direction (A or B)•

The ComPass B is designed for operation in radial, ring and mesh networks.

It can be used in solidly earthed, low-impedance, resonant earthed or isolated neutral systems.

Description of the device2.

Scope of delivery2.1.

A complete set of ComPass B includes:

1 display unit in a plug-in housing for panel mount•

3 single-phase current transformers,•

alternatively: 2 single-phase current transformers and 1 summation current transformer

Integrated voltage detecting system WEGA 1.2 C or WEGA 2.2 C + 1 set of connection•

leads

alternatively: 1 set of HR-interface cable

alternatively: 3 capacitive insulators + 1 set of connection leads.

Display Unit2.2.

Plug-in housing for panel-mount: 96 x 48 x 96 mm (W x H x D), recommended cut-out di-•

mensions according to DIN: 92 +0.8 x 45 +0.6 mm

Voltage supply: 24–230 V AC/DC ±10 %•

Current transformers (CT)2.3.

Single-phase, split core cable-type current transformer for cable/bushing diameters ranging•

from 15 to 55 mm (Order No.: 49-6024-xxx).

Split core cable-type current transformerFigure 1:

Closed single-phase bushing-type current transformer for cable diameter of•

79.5 mm (Order No.: 49-6025-xxx).

Closed bushing-type current transformerFigure 2:

4

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Split core summation current transformer for earth fault detection, for cable diameters ran-•

ging from 40 to 105 mm (Order No.: 49-6023-xxx).

Split core summation current transformerFigure 3:

Make sure current transformers are mounted only on fully insulated i. e. touch-safe conductors.

WEGA 1.2 C and WEGA 2.2 C2.4.

The WEGA 1.2 C or the WEGA 2.2 C is designed as a maintenance-free integrated voltage detec-

ting system that serves to detect and indicate the operating condition of medium-voltage installati-

ons according to VDE 0105, Part 1 and Part 100. The instruments comply with the requirements of

the VDE 0682 Part 415 standard (IEC 61243-5) for capacitive voltage detecting systems.

Besides their main function, WEGA 1.2 C and WEGA 2.2 C, respectively, can provide the tapped

capacitive voltage to the ComPass B in order to measure and detect the fault direction and load

ow.

Integrated Voltage Detecting System WEGA 1.2 CFigure 4:

(without relay contacts)

Integrated Voltage Detecting System WEGA 2.2 C (with relay)Figure 5:

HR-interface cable set2.5.

The HR-interface cable set is used to tap the voltage at capacitive measuring points which is re-

quired for the direction decision and the detection of faults and load ow direction. Various types

are available to cope with different requirements (cable length, connectors) of switchgears offered

in the market.

HR-interface cable setFigure 6:

Example for applicationFigure 7:

5

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Capacitive insulators2.6.

In air-insulated switchgear units capacitive insulators are used for voltage coupling to the

ComPass B.

Example for insulatorsFigure 8:

Device functions3.

Fault detection and fault indication3.1.

Fault detection3.1.1.

Figure 9 below represents a schematic illustration of a medium-voltage network. The ComPass B

is or can be installed in any switchgear unit.

The instrument measures permanently the phase voltages and currents taking these values as a

basis for real time calculations of the neutral point displacement voltage VNE and earth fault current

IE.

Based on these values the ComPass B is able to detect faults in medium-voltage networks and also

to determine their characteristics.

Schematic illustration of a MV networkFigure 9:

6

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

The ComPass B works with the following response criteria:

Overcurrent detection for phase currents (I>>) and earth current (I• E>)

Earth current and neutral point displacement voltage (I• E> & VNE>) for resonant earthed/isolated

networks

Overvoltage (V>) and undervoltage (V<)•

The unit allows individual settings of delay times for all of the above mentioned response criteria.

Whenever one or more of the specied response criteria are met, the ComPass B identies the na-

ture of the error and determines the direction of the fault using the sampled values of the affected

voltages and currents.

Fault direction3.1.2.

Short-circuit/earth fault in solidly earthed & low-impedance systems

As for short-circuits and earth fault in solidly earthed and low-impedance systems, the ComPass B

determines the angle between the fault current and the fault voltage of the affected phases to de-

rive the direction of a fault therefrom. If the impedance angle ranges from -45° to +135°, the Com-

Pass B determines a forward fault (↓B direction).

Earth fault in resonant earthed/isolated systems

As for earth faults in resonant earthed/isolated networks, the ComPass B uses the wattmetric me-

thod. Here the direction of a fault is determined by the phase-to-neutral voltage VNE and the earth

fault current IE.

In some cases it is not possible to determine the direction of a fault, especially when the fault is

located close to the switchgear unit the ComPass B is installed into. In such cases the ComPass B

signals an error without directional indication.

Resonant earthed network operation (cos φ)•

In resonant earthed networks, the ComPass B determines the direction of the active power

of the earth fault (VNE x IE x cos φ)

The ComPass B is provided with an integrated dead zone (non-coloured area, see gure

10) for too low levels of earth fault current IE, or for phase angles that are unfavourably loca-

ted between VNE and IE.

Angle diagramFigure 10:

VNE

7

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Isolated network operation (sinφ)•

In networks with isolated neutral, the ComPass B determines the direction of the reactive

power of the earth fault current (VNE × IE × sin φ).

Angle diagramFigure 11:

Voltage ring buffer3.1.3.

If there is a small distance between the location of the fault and the place of installation of the

ComPass B unit, the phase voltages of the affected phases may become too small to be usefull for

the decision of fault direction. For this reason, the Compass B is provided with a ring buffer. The

measured values of all phase voltages are permanently written into this buffer. In case of a fault

these voltages are extrapolated in time in order to obtain information on the phase relation.

Inrush current suppression3.1.4.

The ComPass B uses an inrush current suppression to avoid unintended tripping due to inrush. The

ComPass B can be adjusted such as to detect faults only when the phase voltages were previously

present for a preset time.

G

This function is deactivated in delivery status!

Fault indication3.1.5.

Faults are indicated locally by the multicolour LED and the OLED display, and remotely indicated

via the RS485/MODBUS interface/relays.

Multicolour LED•

The multicolour LED ashes red as long as ComPass B is indicating a fault.

OLED display•

In case of a fault, the OLED display presents a fault message informing on the type and di-

rection of the fault. For indication press any direction on the rocker switch.

VNE

8

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Short-circuit tripping ↓B Figure 12:

(direction of the line "forward")

Short-circuit faultFigure 13:

Earth fault tripping ↓B Figure 14:

(direction of the line "forward")

Occurrence of an earth faultFigure 15:

Relays•

The ComPass B is provided with 4 relays. Each relay can be congured individually, for

example in order to indicate various fault types and directions, e.g. relay 1 for a phase-to-

phase fault in forward direction, and relay 2 for phase-to-phase fault in reverse direction etc.

If a relay is congured for momentary contact it will engage for 1s for every fault assigned

to it, whereas, if it is congured for permanent contact, it will remain engaged as long as

ComPass B is indicating the fault. If a second fault occurs, it will disengage for 1s and then

re-engage.

RS485/MODBUS interface•

ComPass B stores every fault in its internal memory. The last 20 events are stored including

date, time and data of fault direction (A or B). In addition, also the measured values are

stored at the time the fault is generated and 2 s before the fault occurs. The memory can be

read out either via the RS485/MODBUS interface or manually on the OLED-Display.

Reset modes3.1.6.

ComPass B can be congured to stop fault indication:

after expiration of a pre-dened time (between 1 min and 24 h) •

via external input contact•

locally via the rocker switch•

by remote control via the RS485/MODBUS interface•

on restoration of system voltage•

9

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Measuring the values in a medium-voltage system3.2.

The ComPass B permanently senses the voltage, current and frequency values and performs cal-

culated measurements of P, Q, S and cos φ in medium-voltage distribution networks. It also calcu-

lates the mean values (Ø15 min) and the maximum values (24 h/7 days/365 days, slave pointer).

All values can be read locally on the OLED display or transmitted by remote signals via the RS485/

MODBUS interface.

Operator control3.3.

Front panel3.3.1.

ComPass B can be controlled completely from the front panel which consists of the elements

shown in the gure below.

Front panel control of ComPass BFigure 16:

OLED display•

4x21 alphanumerical characters.•

Multilingual plain text menus (German/English/Dutch/Portuguese).•

Multicolour LED•

Green/Yellow/Red.•

Rocker switch (4 directions)•

Activation of OLED display.•

Navigation through plain text menus.•

Display illumination

In normal operation mode, the display on the front panel is switched off. It is illuminated once the

rocker switch is used (press to any direction). If the rocker switch is not used for 60 seconds, the

display illumination is turned off.

Multicolour LED

The multicolour LEDs signal different operating conditions of the ComPass B (see Table 1). In par-

ticular when the OLED display is not illuminated, the LED gives advanced information that can be

investigated in more detail by the user via the OLED display.

OLED Display

Multicolour LED

Rocker switch

10

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

LED Meaning

green ComPass B is powered from external supply (permanent light)•

No error (permanent light)•

yellow Test mode (single ashing LED) and device error (double ashing LED; •

contact after-sales service)

red Fault in the MV system (LED ashes)•

No indication, external supply not connected.•

No error present.•

Indication of operating conditions by multicolour LEDTable 1:

Rocker switch

The rocker switch is used for navigating the plain text menus on the display.

Up: Scroll up in a menu.1.

Change (increase) a parameter.

Down: Scroll down in a menu.2.

Change (reduce) a parameter.

Left: Leave menu (abort).3.

Jump to main menu.

Right: Call submenu.4.

Save a changed parameter.

1.

4.

3.

2.

Execute a command.

Rocker switchFigure 17:

RS485/MODBUS interface3.3.2.

The RS485/MODBUS interface is used for remote control, remote readout and remote parameteri-

zing of ComPass B.

The ComPass B uses a 2-wire interface according to the RS485 standard with no line termination

in the ComPass B.

The ComPass B is a MODBUS Remote Terminal Unit (RTU) Slave.

Digital inputs/outputs3.3.3.

The ComPass B is provided with 4 digital (relay) outputs and one digital input. Each relay output

can be assigned with individual functionality either via the front panel control or the RS485/MOD-

BUS interface.

Power Supply3.4.

The ComPass B is powered by an external 24-230 V AC/DC ±10 % supply. An incorporated lithium

cell provides the energy in case of lack of external voltage supply, so the readout of all saved data

is ensured in case of a fault.

If external power supply stops, the ComPass B will stop short-circuit and earth fault detection as

well as MV network monitoring and communication via the RS485/MODBUS interface. It is ensured

that the relays are energized, even in case of a fault.

11

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Test mode3.5.

The ComPass B features a built-in test mode. This mode can be activated via the

front panel control•

RS485/MODBUS interface•

external input contact•

During test mode, the ComPass B controls both its electronics and its software. The yellow light of

the multicolour LED starts ashing to indicate the test mode.

If an error is detected on the device, the multicolour LED ashes yellow, either in a double or triple

ash mode which depends on the type of error. Further information on the error can be gathered

either from the front panel control or via the RS485/MODBUS interface (see section 3.1.5).

Installation4.

Safety instructions4.1.

Make sure that the ComPass B is only used for the purpose described in the present opera-•

ting manual.

When installing the device, the “ve safety rules” as dened by the DIN VDE 0105 standard •

and the accident prevention rules as per BGV A3 “Electrical Installations and Equipment”

must be complied with.

Make sure that current transformers are mounted and dismounted and cabling work is exe-•

cuted only in a de-energized condition on the disconnected and earthed medium-voltage

switchgear.

If current transformers remain in the switchgear without being connected to the indicator,•

the leads must be applied to suitable insulated terminals ensuring that such leads are short-

circuited.

Plug-in housing for panel mount4.2.

Insert the plug-in housing into a prepared DIN size cut-out of 92+0.8 mm x 45+0.6 mm on the front of

the switchgear panel and lock it by means of 4 integrated spring clips with self-retaining feature.

Provide a minimum installation depth of 95 mm with connected leads.

If you need to dismount the device, remove the front frame and front plate pushing the retainer

spring clips towards the centre of the device (Order No. of Disassembly Clip: 040401-0008).

Installation of current transformers (CTs)4.3.

General4.3.1.

The CTs are split-core types (allow also for subsequent mounting) and are mounted on insu-•

lated conductors.

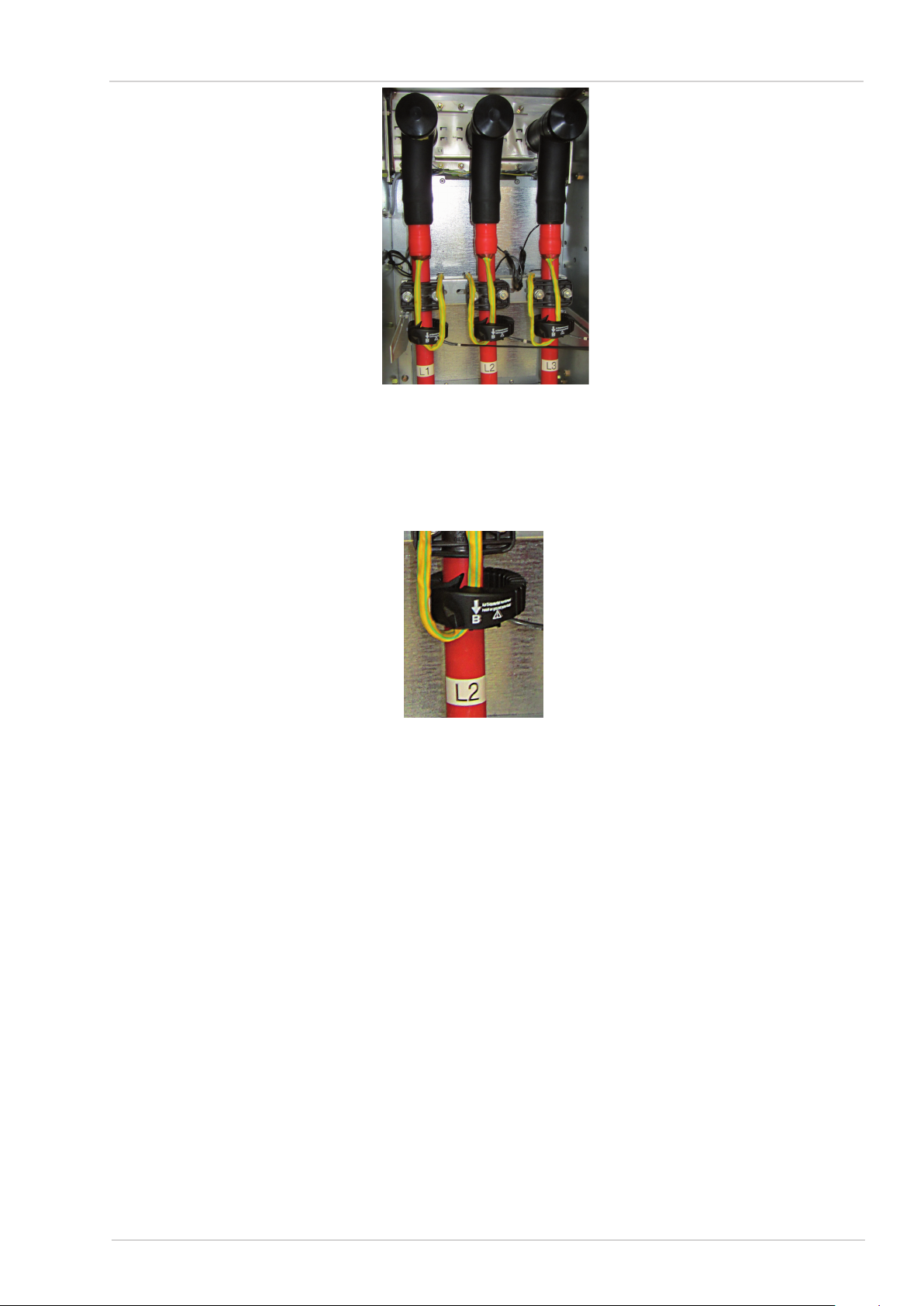

Ensure shielding of each conductor is repassed through the yoke of the CT to compensate•

any shield currents (see illustration 18). On connecting the wires to the ComPass B mind

the allocation of the cable lead colours (brown/blue) to the terminals (marking br/bl) and the

respective L1, L2, L3 phases.

G

Make sure current transformers are mounted only on fully insulated i. e. touch-safe conduc-

tors.

12

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Installation of current transformersFigure 18:

Installation of single-phase current transformers4.3.2.

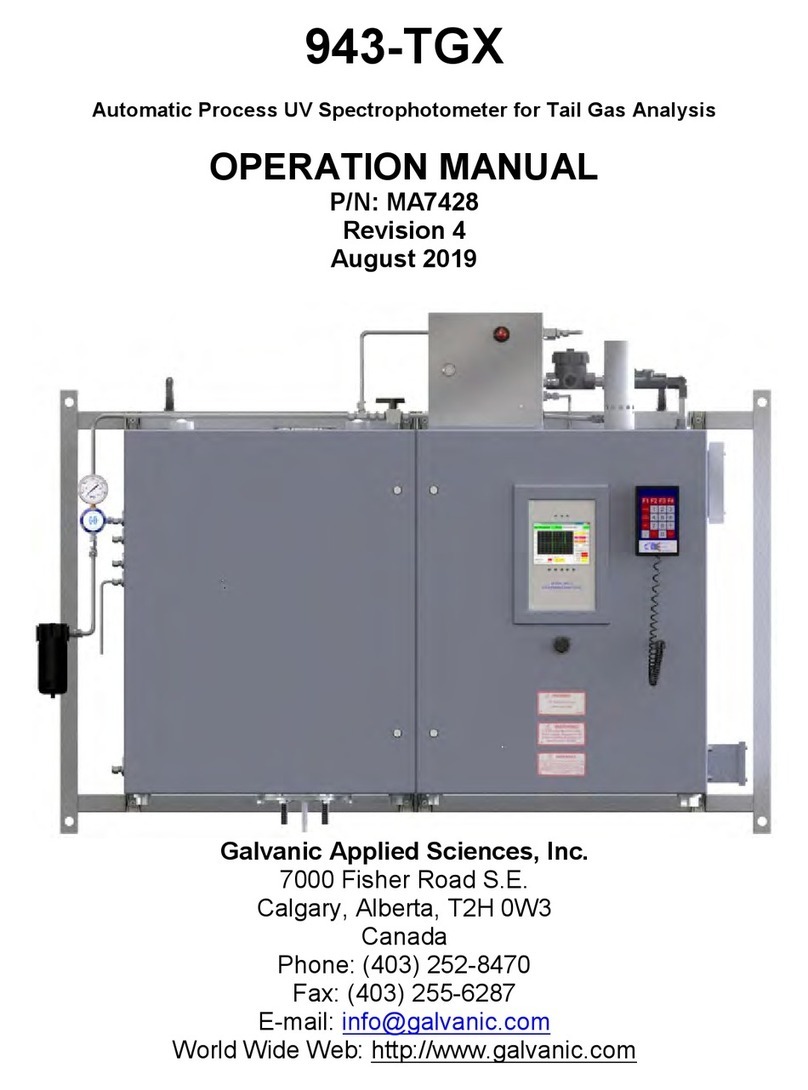

Install each CT as to ensure that the arrow and the "↓B" show towards the bottom of the switchgear.

Direction indication "↓B"Figure 19:

Installation of summation current transformers4.3.3.

Wrap the CT around all 3 conductors and install it such that the arrow and the "↓B" show towards

the bottom.

13

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Electrical connection4.4.

Terminal strips4.4.1.

The terminal strips are located in the rear wall of the instrument. If provided on the side of the

switchgear, perform electrical connection according to the following terminal reference list (See also

circuit diagram on the top side of the instrument, numerical arrangement from right to left). Use fer-

rules of L=6 mm, max. 0.75 mm2 .The maximum permissible tightening torque is 0.4 Nm.

Assignment of terminal strips4.4.2.

Circuit diagram on top side of the instrumentFigure 20:

CT/Digital I/O/Supply Voltage

Terminal No Designation Assignment Direction

1 I1 br CT Phase 1 (brown) Input

2 I1 bl CT Phase 1 (blue) Input

3 I2 br CT Phase 2 (brown) Input

4 I2 bl CT Phase 2 (blue) Input

5 I3 br CT Phase 3 (brown) Input

6 I3 bl CT Phase 3 (blue) Input

7Earth Input/Output

8 Input External input Input

9 Input External input Input

10 K1 Relay 1 Output

11 K2 Relay 2 Output

12 K3 Relay 3 Output

13 K4 Relay 4 Output

14 | Common contact for all relays Output

15 24-230 V ~/+ 24-230 V AC/DC ~/+ Input

16 24-230 V ~/- 24-230 V AC/DC ~/- Input

Terminal assignment of CT/Digital I/O/Supply VoltageTable 2:

14

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

G

Important note for the connection of the external input (see Table 2)

For activation of the functions use potential-free contacts, e. g. coupling relays or tra-•

cers.

Use separate potential-free contacts for each indication device.•

If the functions of several devices shall be operated in parallel, the triggering disconnec-•

ting elements (relay outputs, coupling relays etc.) are to be operated in parallel.

Operational earth or other "GND" potentials are inappropriate as common reference po-•

tential.

Use a momentary contact for triggering (momentary time 1-5s), but not a permanent•

contact.

MV interface

Terminal No. Designation Assignment Direction

1Earth Input/Output

2 U1 Voltage/Phase 1 Input

3 U2 Voltage/Phase 2 Input

4 U3 Voltage/Phase 3 Input

Terminal assignment of MV interfaceTable 3:

RS485/MODBUS interface

Terminal No. Designation Assignment Direction

1 COM Common Input/Output

2 RES Reserved Reserve

3 RES Reserved Reserve

4 RES Reserved Reserve

5 B D1/RS485 "B" Input

6 A D0/RS485 "A" Input

Terminal assignment of RS485/MODBUS interfaceTable 4:

Device conguration and commissioning5.

Device configuration5.1.

ComPass B is delivered with a standard factory setting (see Appendix A) which, in most cases,

meets all requirements. Some parameters (see Table 5) however need to be set and checked indi-

vidually which can be carried out either via the front panel control or the RS485/MODBUS interface.

G

Any alteration in the conguration should be carried out while assuring that the ComPass B is

supplied by an external supply, otherwise parameter storage may fail.

15

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Short-circuit trip current → Settings I>>

Short-circuit current delay time → Settings tI>>

Earth fault trip current → Settings IE>

Earth fault delay time → Settings tIE>

Time reset → Settings tReset

Language → Settings Language

Short-circuit current transformer → Settings CT

Earth fault current transformer → Settings SUM-CT

Frequency → Settings Frequency

Rated voltage → Settings VNom

Neutral earthing → Settings NeutralPt

Relay type → Settings Type

Relay mode → Settings Mode

Parameter setting in the ComPass BTable 5:

Voltage calibration5.2.

Step 1:

G

Voltage calibration is required after ComPass B has been installed in the switch-gear and the

switch-gear has been energised.

Below voltage calibration is carried out using the example of a 11 kV network.

Step 2:

Voltage calibration is possible only, if medium voltage is applied to the switch-gear. The bushings of

the switchgear or the capacitive insulators on the primary side must be connected to a three-phase

medium voltage.

G

If there is no precise reference voltage available, ComPass B must be calibrated using the

network voltage with the impending power supply. In this case, continue with step 4.

Setting the medium-voltage parameterStep 3:

Example: 11 kV system

Un= 11 kV resp.

ULE = Un/√3 = 6,35 kV

Software for the determination of data settings (example).Figure 21:

16

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

ComPass B menu settings for voltage calibrationStep 4:

Select menu:

Settings →↓ Expert Mode →↓ Grid parameter

- Set frequency to 50 Hz

- Set VNom to 11.0 kV (Voltage used in this example !)

Select menu:

Settings →↓ Expert Mode →↓ V-Calibration

Set VCAL_LL to 11000V.

Note: VCAL_LE entry is changed automatically.

G

Alternatively, set VCAL_LE parameter whereupon

VCAL_LL is changed automatically.

Select entry „Start calibration“ and push rocker switch to the

right.

If the following security prompt appears, V-AutoCal?

=> Select “Yes”.

Note: Presence of calibration voltage of 11 kV/6.35 kV is requi-

red!

Indication on the display during the calibration process.

Indication on the display after calibration has been completed.

Correction values are stored.

Push rocker switch to the left!

Step 5:

Indication:

- Voltage is calibrated.

- Date of calibration.

- Calibration valid for medium-voltage range.

Verification if calibration has been successfully completed:

Applied calibration voltage shall be identical with the voltage va-

lue indicated on the display (to be found in the menu under mea-

surement results).

17

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Commissioning5.3.

The ComPass B is ready for operation after the following works have been completed: “Installation”

according to section 4, “Device conguration” according to section 5.1 and “Voltage calibration” ac-

cording to section 5.2.

Technical Data6.

Mechanical data

Plug-in housing for panel mount 96 x 48 x 96 mm (W x H x D)

DIN-cutout dimensions in the switchgear 92+0.8 x 45+0.6 mm

Weight of display unit 240 g

Degree of protection IP40

Electrical data

Power supply Internal supply: 3.6 V lithium cell, with 20-year shelf life

>1000 h total ashing time of the LED

>1000 activations of the display

External supply: 24-230 V AC/DC ±10 %

Power consumption <1 W (DC supply)

<1.5 VA (AC supply)

MV network parameters

Rated voltage 1–36 kV

Frequency 50 Hz/60 Hz

Load current (single-phase) 0–630 A

Short-circuit trip current 50–2000 A

Short-circuit response delay 40 ms < t < 60 sec

Earth fault trip current 20–1000 A (low-impedance/solidly earthed system)

5–200 A (isolated/resonant earthed system)

Earth fault response delay 40 ms < t < 60 sec

Reset options by automatic reset (1 min to 24 h), or

via external contact, or

by means of the rocker switch on the front side, or

on restoration of voltage/current, or

via RS485/MODBUS interface

Current measurement accuracy:

0 A – 630 A 3 % (Resolution 1A)

630 A – 1500 A 5 %

1500 A – 2000 A 10 %

Voltage measurement accuracy: ≤ 10 % (automatic calibration)

≤ 1 % (when using reference voltage for voltage

calibration)

18

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

External input for connection of a potential-free contact,

congurable function

Digital outputs 4 relays

NC/NO

Permanent contact/momentary contact (1 s)

Contact capacity: 230 V AC/1 A/62.5 VA max.

220 V DC/1 A/60 W max.

Breakdown voltage: 1.5 kV, 1 minute

Current transformers (CT) 3 pcs. single-phase CT (L1, L2, L3)

alternatively: 2 pcs. single-phase CT +

1 pc. summation CT

Environmental Conditions

Operating temperature -30° C... +70° C

19

Dipl.-Ing. H. Horstmann GmbH

Instructions for Use

ComPass B 4023841-001

Settings Assignment Asjustment Default Customer

setting

Basic setting

I>> Short-circuit trip current 50-2000 A 400 A

tI>> Short-circuit response delay 40 ms-60 s 80 ms

IE> Earth fault trip current 1-1000 A (<10 A nur

mit SUM-CT)

200 A

tIE> Earth fault response delay 40 ms-60 s 160 ms

tReset Time reset of the fault indica-

tion and relays

1 min – 1440 min

(24 h)

240 min (4 h)

Expert mode

Language Deutsch

English

Nederlands

Portugues

English

Sensor

Current transformer

(CT)

CT = short-circuit current

transformer

----------------

49-6023-00X

49-6024-00X

49-6025-00X

49-6024-00x

SUM-CT = earth fault current

transformer

------------

49-6023-00X

----------------

Grid parameter

Frequency 50/60 Hz 50 Hz

VNom Nominal voltage 1-36 kV 10.0 kV

Neutral earthing low-impedance earthed

temporary low impedance

earthes

isolated earthed

Resonant earthed

Low-ohmic

KNOSPE

Isolated

Resonant earthed

Low-ohmic

Relais (Each relay has the following conguration options. The standard congurations are available Relay 1 to Relay 4

at the end of this section.)

Type Relay basic setting NO = Normaly Open

NC = Normaly

Closed

Normaly Open

(NO)

Mode Relay basic setting Momentary

Permanent

Momentary

Function

I>> Relay responds to short-

circuit (non-directional)

On

Off

Adjustable for

each relay

I>> A Relay responds to short-

circuit direction A

On

Off

Adjustable for

each relay

I>> B Relay responds to short-

circuit direction B

On

Off

Adjustable for

each relay

Appendix A: Parameterization ComPass B

For unambiguous assignment of the device transfer your serial number (see sticker top panel):

S.No. ........................

20

Dipl.-Ing. H. Horstmann GmbH

Table of contents

Popular Measuring Instrument manuals by other brands

Galvanic Applied Sciences

Galvanic Applied Sciences 943-TGX Operation manual

Hanna

Hanna HI 991300 instruction manual

Endress+Hauser

Endress+Hauser Proline Prosonic Flow 92F Safety instructions

Circutor

Circutor CVM-E3-MINI instruction manual

Airflow

Airflow Silent+ Mini Orange instruction manual

RX only

RX only stryker user guide