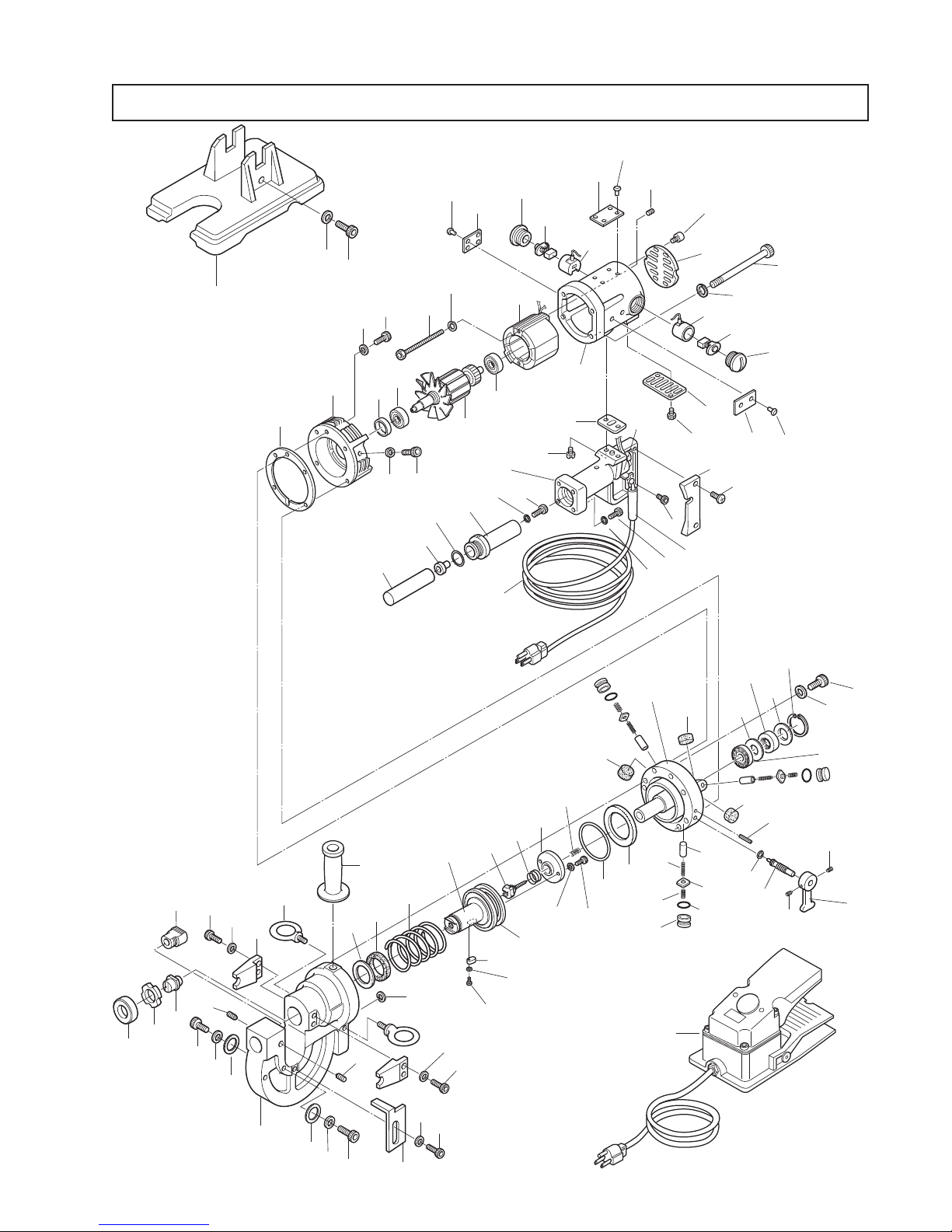

10

NOTE: The internal components of the pump and piston area have very close clearances and are sensitive

to damage from dust, dirt, contamination of the hydraulic uid or improper handling. The disassembly of the

pump housing requires special tools and training, and should be attempted by a qualied repair person. The

improper servicing of electrical components can lead to conditions that could cause serious injury.

ANY ATTEMPT BY UNAUTHORIZED PERSONNEL TO SERVICE THE INTERNAL COMPONENTS OF

THE PUMP AREA WILL VOID THE WARRANTY.

Inordertoinsuresmootheroperationandlongerlifeofyour

holepuncher,thefollowingmaintenanceshouldbedone

periodically,basedonuse.

1. Keepthemachineclean.Itisespeciallyimportantto

keeptheslidingportionofthepunchpistonfreefrommetal

chips,scale,dirt,dustorotherdebris.Tocleanthepunch

piston,turnontheswitchtomovethepunchpistonalmost

tothebottomofitsstroke.Ifnecessary,cyclethepunch

severaltimestodeterminewherethebottomofthestroke

is,andtocorrectlypositionthepunchpiston.

Unplugthepowercord.Wipeanydebrisfromtheex-

posedpartofthepunchpiston.

2. Regularlytightenallfastenersandreplaceany

worn components.

3. Checkpowercord,ifcrackedorfrayed,returnthe

machinetoanauthorizedrepaircenterfor

replacement.

4. Checkoillevel,carefullyusingtheprocedurebelow.

ADDING OIL

4. Carefullyopentheoilportbyremovingthesocket

headcapscrew.

5. Usingthesmallsqueezebottlesuppliedwiththe

HolePuncher,carefullyaddhydraulicoiltocompletely

llthereservoir.RocktheHolePuncherbackandforth

slightlyseveraltimestofreeanytrappedairbubbles,

thenaddadditionaloilifnecessary.

6. Replacethecapscrewandwipeupanyexcessoil.

7. CycletheHolePuncherseveraltimeswiththe

ManualreturnValveopen,andagainwiththevalve

closed,toworkanytrappedairoutofthesystem,

thenrepeattheaboveprocedure,makingsurethatthe

punchpistonisalmostatthebottomofthestroke

beforeremovingthecapscrewfromtheoilport.

8. Addadditionaloilasnecessary.Iftheunitwas

extremelylowonoil,itmaybenecessarytorepeat

theprocedureseveraltimes.

MAINTENANCE

HELPFUL HINTS FOR HOLE PUNCHING

Eachofthepunchesisprovidedwithasharppointatits

center.Iftheholelocationsarecenterpunched,thepoint

ontheendofthepunchmaybeusedto"nd"thecenter

punchedspot.

Also,foraccurateandeasypositioningofthepunchtoa

holelocation,theswitchcanbeintermittentlypulsedon

andofftojogthepunchdowntotheworksurface.

Ifthepositionisnotsatisfactory,openthemanualreturn

valvetoretractthepunchforanotherattempt.This

operationcanalsobeperformedwiththemanualreturn

valve"cracked"openslightlytopreventfullpunching

pressurefrombeingdeveloped.Inthismanner,the

punchcanbeeasilybroughtrightdowntothesurface

withoutbeginningtopunchthehole.Ifthelocationis

satisfactory,closethevalveandnishtheoperation.

Useofthecorrecthydraulicoilisessential.Approvedoils

areShell"TELLUSOil"andExxon"TERESSTIC"(Part

No.75377).Grade#32viscositymustbeused.Checkthe

unitspecications.Makesurethattheworkareaandall

equipmentarecleansothatnodirt,dustorotherforeign

materialcangetintothehydraulicoilorpumparea.

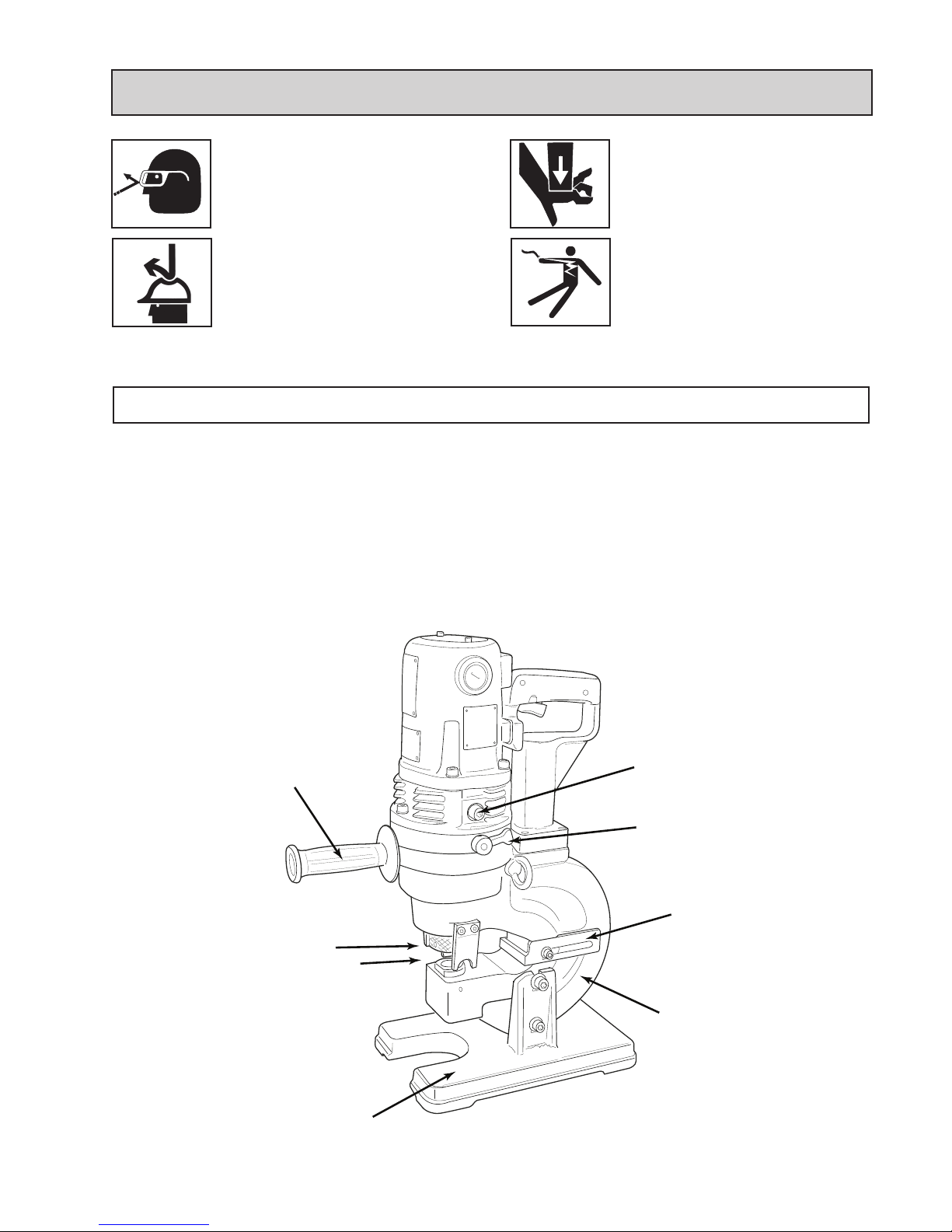

1. Locatethesocketheadcapscrewthatplugstheoilport.

Itisjustabovethemanualreturnleverontherighthand

sideoftheHolePuncher.

2. LaytheHolePuncheronitsleftsidesothattheoilport

is facing up.

3. Turnontheswitchtomovethepunchpistonalmost

tothebottomofitsstroke.Ifnecessary,cyclethepunch

severaltimestodeterminewherethebottomofthestroke

is,andtocorrectlypositionthepunchpiston.Inthisposi-

tion,themaximumamountofoilhasbeendrawnfromthe

pumpandthecorrectllcanbeobtained.

WARNING! Failure to check punch retaining nut periodically during use, can result in

personal injury or damage to your unit.