www.powertoolrepairohio.com

Power Tool Repair

371 West Ave.

Tallmadge, OH 44278

(330) 630-0022

Air Tool Maintenance and Repair

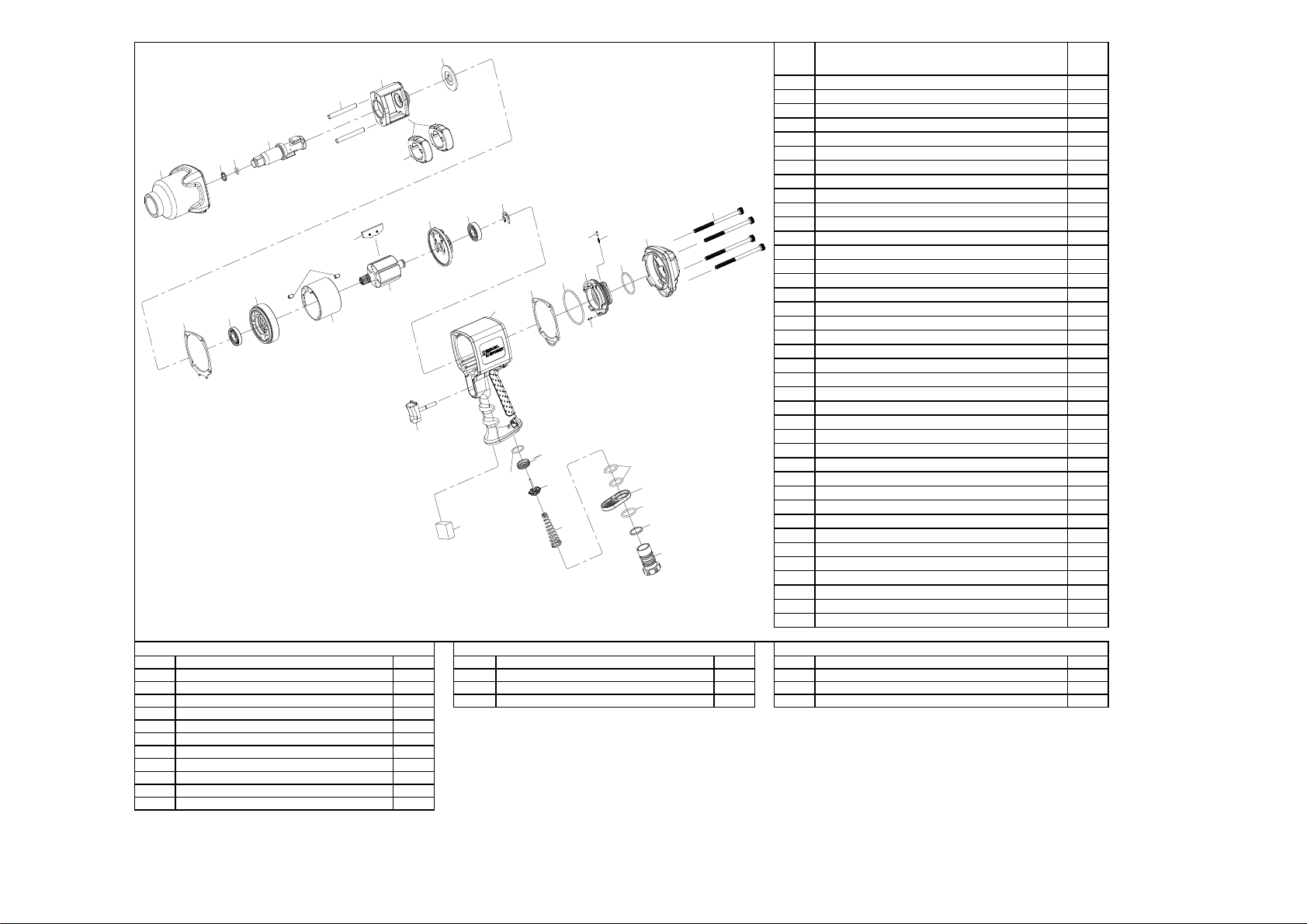

2) Hammer and Anvil

1) Air Motor Rotor Blades

1) Air Motor Rotor Blades

2) Hammer and Anvil

3) Socket Retainer and O-Ring

This tool contains multiple parts that are “normal wear

items”. These parts can all be serviced/replaced by the

user, or the tool may be sent to the Service Center.

Tools returned to the Service Center for normal wear

parts will incur service charges. Some of the critical

common wear items include:

Manufacturer’s Limited Warranty

This Kimball Midwest product is warranted to be free from

defects in material and workmanship for one year from the

date of purchase. This Warranty applies only to products

purchased new from Kimball Midwest. This Warranty does not

apply to normal wear and tear or to products which have been

abused, misused, modified, or repaired by someone other than

Kimball Midwest’s Authorized Service Center. If this Kimball

Midwest product proves defective in material or workmanship

within one year after purchase, return it to the Kimball Midwest

Authorized Service Center, transportation prepaid, enclosing

your name and address, proof of date of purchase, and a short

description of the defect. Kimball Midwest will, at its option,

repair or replace the defective product free of charge. Repairs

or replacements are warranted as described above for the

remainder of the original warranty period. Kimball Midwest’s

sole liability and your exclusive remedy under this Warranty is

limited to repair or replacement of the defective product.

(There Are No Other Warranties Expressed Or Implied And

Kimball Midwest Shall Not Be Liable For Incidental,

Consequential, Or Special Damages, Or Any Other

Damages, Costs Or Expenses Excepting Only The Cost Or

Expense Of Repair Or Replacement As Described Above.)

Normal wear items are not manufacturer's defects. Some of the

common normal wear items are contained in the following repair

kits: 84-0351, 84-0352 and 84-0353.

Maintenance– Using filtered, compressed air with

either automatic airline lubrication or frequent manual

lubrication will extend the service life of the Air Motor

Rotor Blades.

Maintenance– The rotating action of the Hammer as it

impacts the Anvil allows the tool to apply force to

fasteners. These components are greased from the

factory. However, this grease will gradually lose its

lubricating capability over time, causing metal-on-metal

wear. Use a 4mm hex key to remove the 4 socket head

cap screws to take off the back cover of the tool. Clean

out and replace the old grease with fresh, high-quality

impact grease.

3) Socket Retainer and O-Ring

Maintenance– The Socket Retainer and O-Ring are located

at the very tip of the Anvil (square drive) of the tool. The

Socket Retainer is a round C-clip, and its underlying O-Ring

allows the clip to expand and contract to securely hold impact

sockets and other square drive accessories onto the tool.

They do not require maintenance, but they can become worn

after frequent use.

Repair – When the free speed of the tool becomes

slower, or the tool begins to vent air without rotating, the

Rotor Blades may be worn or contaminated with sludge

and other debris. Use a 4mm hex key to remove the 4

socket head cap screws to take off the back cover of the

tool and inspect the Air Motor Rotor Blades. If the Rotor

Blades do not slide freely in and out of the slots on the

Air Motor Rotor, they should be replaced. The General

Maintenance Kit (84-0351*) contains new Rotor Blades

and several other related common replacement

components. The Rotor Blades can be easily removed

and replaced by hand. Use a high-quality air tool

conditioning oil to clean the Air Motor Rotor when

installing new Rotor Blades.

Repair – When impact sockets and other square drive

accessories can no longer be securely attached to the tool

without easily falling off, it is time to replace the Socket

Retainer and O-Ring. Use a small metal pick to pry off the old

Socket Retainer and the underlying O-Ring. The Anvil Repair

Kit (84-0353*) contains a new Socket Retainer and O-Ring

(along with a replacement Anvil).

Repair – When the tool begins to skip and/or lose

power during use, it is likely that the Hammer and/or

Anvil have become worn. Remove the 4 socket head

cap screws and the back cover to replace and re-grease

the Hammer and Anvil. If the Hammer and Anvil have

been re-greased and the problem persists, these items

should be replaced. These components easily slide out

of the tool by hand. Ideally, the Hammer and Anvil

should be replaced as a set; however, replacing either

one or the other may restore performance to the tool.

The Hammer Repair Kit (84-0352*) contains a new

Hammer and hammer assembly components. The

Anvil Repair Kit (84-0353*) contains a new Anvil.

*(Please refer to the Exploded Parts Diagram in this manual

for the complete contents of each repair kit.)