ST 400

16

AT ALL TIMES

• Use the machine only for the purpose for which it has

been designed, and in accordance with the instructions

in this operators manual.

• Ensure that only responsible, properly instructed people

operate this machinery. Inexperienced operators will

require training, followed initially by careful supervision.

• Children are not permitted to operate this machinery.

• Keep children well clear and appropriately supervised

when connecting/disconnecting the tractor, operating or

maintaining this machinery.

• Donotwearclothes that areloosefittingorwithdrawstring

ties which can catch in moving parts.

• Wear appropriate protective clothing and equipment.

Boots are a minimum, however if your tractor is not fitted

with a controlled environment cab you may also need

protection from prolonged exposure either to noise, dust

or sunlight.

• Interpret ‘Left’ and ‘Right’ as if seated in the operators

seat and facing forward.

BEFORE OPERATION

• Read and understand this manual.

• The tractor to be connected to the machine:

- Must be the tractor that the machine has been

commissioned to operate with. Check that it has been

correctly maintained and has not been re-configured

(for example front weights removed etc) which may

reduce stability and control.

- Consult the Tractor Manufacturers Manual for

instructionson mountingimplements and safeworking

methods.

- Isrecommended to befitted with aRollOver Protection

System (ROPS).

- Must be one the operator is familiar with.

• Priorto startingthetractor ensurethe PTO isdisengaged

and the tractor is in neutral.

• Do not allow anyone to stand between the tractor and

machine while backing the tractor up to attach it.

- Quick hitch systems are recommended for both Safety

and convenience.

- Before attempting to connect the universal drive shaft

to the tractor, lower the machine to the ground, stop

the tractor, apply the park brake and remove the key.

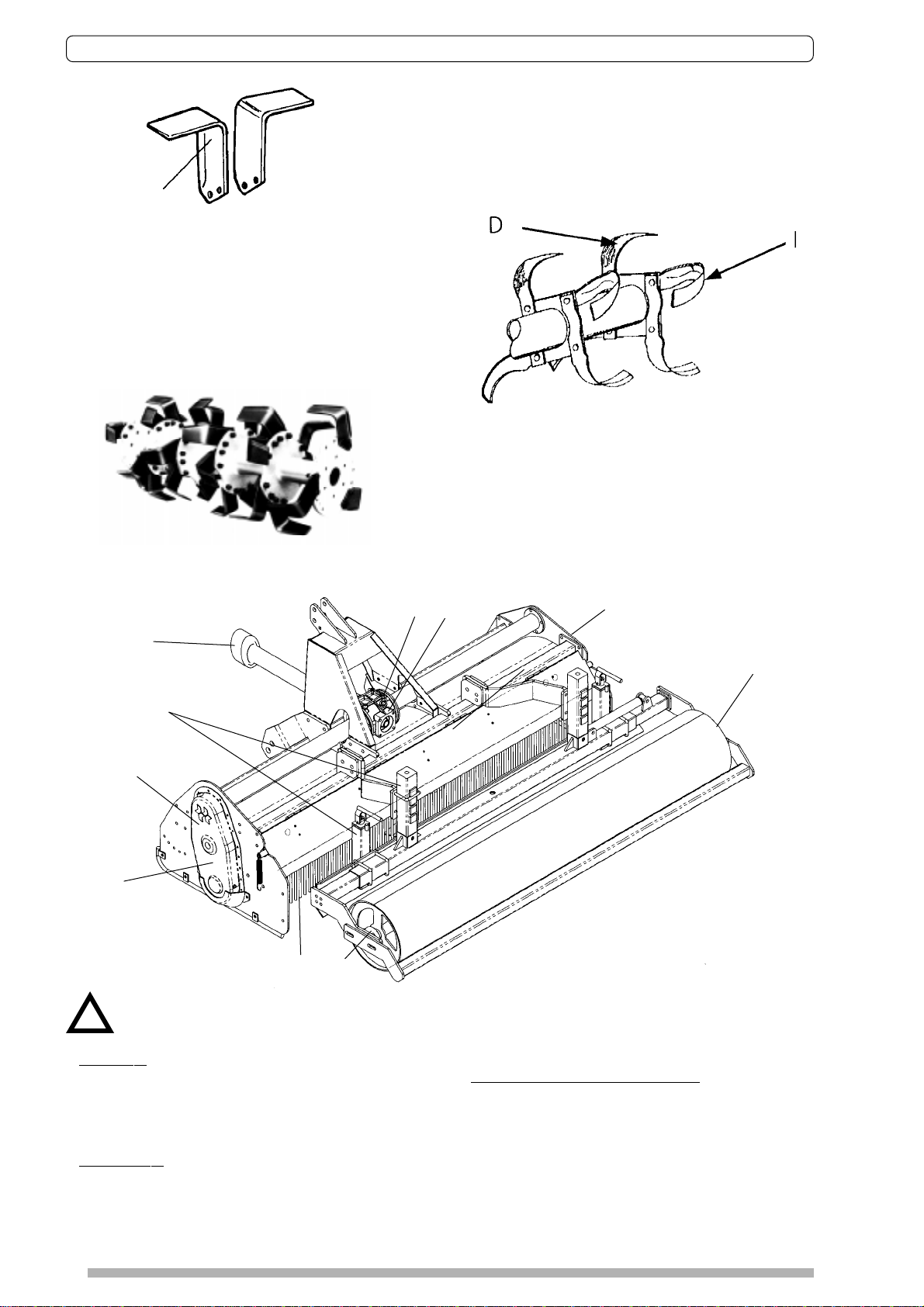

• Visually inspect the machine and check:

- Hitch pins and drive shaft are secure.

- No components are excessively worn, cracked or

otherwise defective and all bolts are tight.

- Guards, covers, warning labels and safety devices are

all correctly fitted and operative.

- Maintenance as per schedule has been carried out.

- No tools or other unsecured items have been left on

the Rotavator.

• Practice operation of the tractor and machine

combination.

- Take sufficient time to become completely familiar with

all controls, particularly those required to bring both

tractor and machine to an emergency stop if so

required.

- Progressslowlyinitially and checkstability, steering and

braking are satisfactory.

• Ensure the work area is clear, especially of children or

animals.

• Inspect the work area for hidden obstructions which may

constitute a hazard.

DURING OPERATION

• Ensure the work area is clear, especially of children or

animals.

• Do not attempt to start the tractor or engage the PTO

until correctly seated in the driver’s seat.

• Never leave the tractor running unattended.

• Donot allowpassengers on themachine. [Oronthe trac-

tor unless approved seating is available.]

• Never attempt to make adjustments or perform

maintenance functions while the machine is operating.

• Observe all safe driving procedures:

- Reduce speed when working on sloping ground or

during sharp turns.

- Donotattempt to workonsteeplysloping ground where

there is a risk of the tractor overturning.

- Do not attempt to work near the edge of drop-offs or

banks.

- Avoid sudden starts and stops.

• After striking an obstacle, stop the tractor and implement

and inspect it for damage. Repair as necessary before

continuing.

• Disengage the PTO when transporting the implement or

when not in use.

• When halting operation, even temporarily, lower the

machine to the ground, stop the tractor, apply the park

brake and remove the key.

• Allow the machine sufficient time to cool down before

performing any maintenance, or changing gears in the

Selectaspeed gearbox. [Oil and other transmission

components may be hot enough to inflict burns.]

• Note:

- By virtue of its mode of operation it is not possible to

totally enclose a machine with guards.

- Contact with the blades while operating can result in

severe injury or death.

- Do not allow anybody (operators, maintenance

personnel,bystandersor especiallychildren) anywhere

nearthe blades whilsttheimplement is operating. Note

that children will often be attracted to placing objects

into the blades if you leave it running - this machine is

not a toy.

- Be aware that machine blades will not only cut, but

drag limbs etc. into further danger.

- Ensurethat allshielding isin placebefore operating. If

guardsareremoved formaintenance work,ensurethey

are replaced correctly upon completion. Repair or

replace any damaged guards.

- NEVER place hands or feet under the machine, nor

endeavour to make any repairs or adjustments while

the blades are rotating; they are capable of inflicting

serious injury.

- NEVERtouchthe bladesor attempttofree any jammed

obstacle while the tractor engine is running.The clutch

may be slipping and removal of any obstruction may

allow the blades to rotate, the result possibly being

serious injury.