Figure 5 Installing a hard disk drive

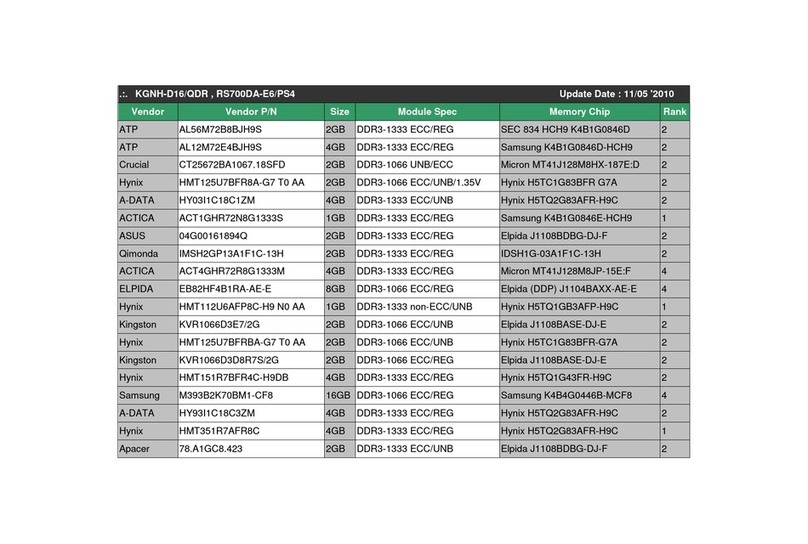

Installing a Memory Module

The following guidelines must be followed when memory modules are being added

or replaced:

• The server has 12 DIMMs slots, six DIMM slots per processor, three DIMM slots

per channel.

• Up to 128GB, using PC3-8500R DDR3 Registered (RDIMM) memory, operating

at 800MHz when fully populated in 12 slots.

• Up to 32GB, using PC3-10600E DDR3 Unbuffered (UDIMM) memory, operating

at 1066MHz when fully populated at 2 DIMMs per channel in 12 slots.

• 4R (Quad-Rank) Registered (RDIMM) memory is supported in DIMM slots 2E

and 5F of both processors.

• Supported congurations:

o One DIMM per processor: 1A for CPU1; 1A for CPU2.

o Two DIMMs per processor: 1A, 4B for CPU1; 1A, 4B for CPU2.

o Four DIMMs per processor: 1A, 4B, 3C, 6D for CPU1; 1A, 4B, 3C, 6D

for CPU2;

oDIMM population order for processor socket 1: 1A, 4B, 3C, 6D, 2E, 5F.

o DIMM population order for processor socket 2: 1A, 4B, 3C, 6D, 2E, 5F.

Figure 6 DIMM slot population sequence

CAUTION: DIMMs can be damaged by improper handling. Always

use an anti-static wrist strap and grounding mat, and discharge static

electricity before touching DIMMs.

To install a memory module:

1. Align the notch on the bottom edge of the module with the keyed surface of the

DIMM slot and then press the module fully into the slot.

2. Firmly press the holding clips inward to secure the memory module in place.

Figure 7 Installing a memory module

DIMM slots are structured to ensure proper installation. If you insert a DIMM but

it does not t easily into the slot, you may have inserted it incorrectly. Reverse the

orientation of the DIMM and insert it again.

Installing a Processor

The server supports AMD 4100 Series Processors High Wattage 75W (6 Core and

4 Core), 50W (6 Core), and Low Wattage 32W (6 Core).

NOTE: If one processor is being installed, it should be installed in the socket closest

to the SR5690 chipset.

To install the processor:

1. Open the processor retaining latch and the processor socket retaining bracket.

Figure 8 Open the processor socket

IMPORTANT: Be sure the processor remains inside the processor

installation tool.

2. If the processor has separated from the installation tool, carefully reinsert the

processor in the tool.

Figure 9 Installing a processor in the installation tool

3. Align the processor installation tool with the socket and install the processor.

Figure 10 Installing a processor

4. Press down rmly until the processor installation tool clicks and separates from

the processor, and then remove the processor installation tool.

Figure 11 Removing the processor installation tool

5. Close the processor socket retaining bracket and the processor retaining latch.

Figure 12 Closing the processor socket

For processor removal, reverse the above installation procedures.

To install the heatsink:

CAUTION: Be sure that the heat sink sits squarely on the processor, or

overheating and damage to the processor may occur.

CAUTION: Heatsink screws should be tightened and loosened in opposite

sequence. Do not overtighten the screws as this can damage the system

board, connectors, or screws. A maximum torque of 6-8 in-lb is set for the

system.

1. Position the heatsink on the processor backplate.

2. Tighten the rst screw about three quarters in, then tighten the second screw

completely.

3. Completely tighten the rst screw.

Figure 13 Installing the heatsink

IMPORTANT: If the heat sink has been removed for any reason, it is

critical that you apply more thermal interface material to the integrated

heat spreader on the processor to ensure proper thermal bonding

between the processor and the heat sink. Clean the contact surface of

both the processor and heat sink with an alcohol pad, then re-apply an

HP-approved thermal interface material before reinstalling the processor.

Use a pattern of five dots when applying the thermal interface material—

one dot in the center, and one dot at each corner.

Additional Documentation

For additional documentation, refer to HP ProLiant SL335s G7 Server Documentation

CD. You can also access additional information and documentation from the HP

external website, either by connecting directly or through the Documentation CD.

Documentation Feedback

HP is committed to providing documentation that meets your needs. To help us improve

the documentation, send any errors, suggestions, or comments to Documentation

Feedback (mailto:docsfeedback@hp.com). Include the document title and part number,

version number, or the URL when submitting your feedback.