EL-MF877-00 Page 2

Template Revision A

2.0 Tools Required

List the type and size of the tools that would typically be used to disassemble the product to a point where components

and materials requiring selective treatment can be removed.

Tool Description Tool Size (if

applicable)

Torx screwdriver T5, T8 & T10

Crosshead screwdriver Large

Small pliers N/A

3.0 Product Disassembly Process

3.1 List the basic steps that should typically be followed to remove components and materials requiring selective treatment:

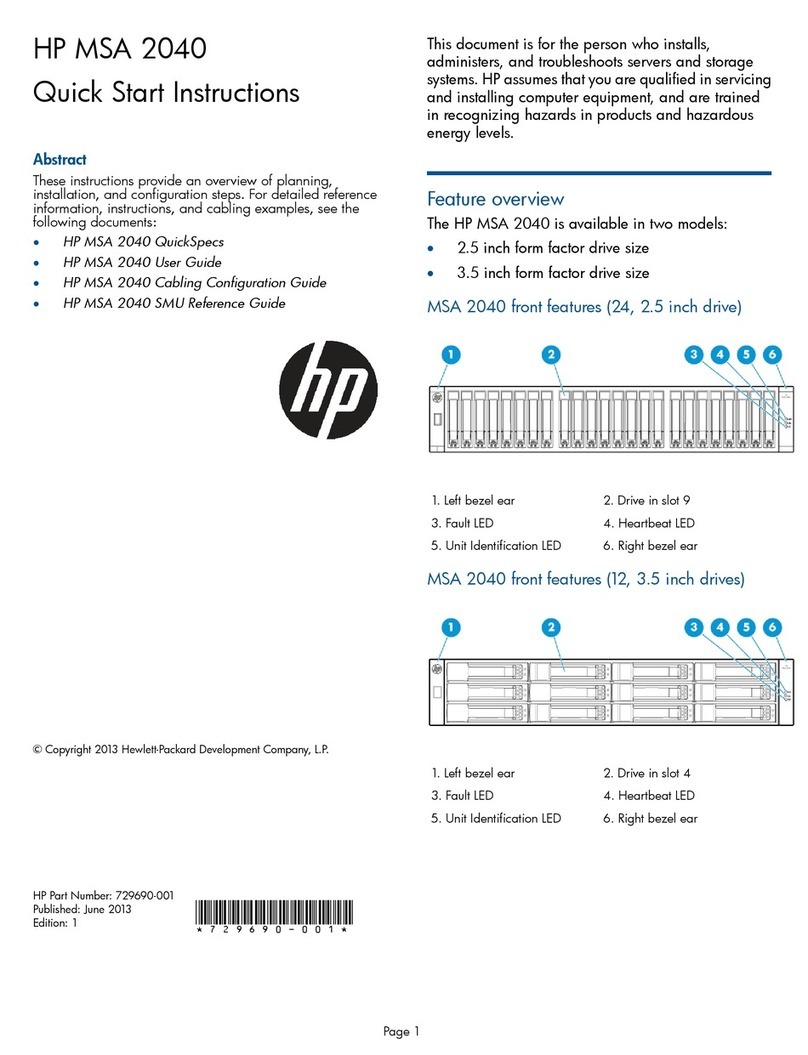

3.1.1 Remove the lid and front bezel. 5 x T-10 screws; 4 x underneath and 1 from the rear and clip off the front bezel.

3.1.2 Remove the mechanism from the enclosure chassis. 2 x T-10 screws at the rear of the mechanism; 4 x T-10

screws at the front of the mechanism –1 x either side of the front panel and 2 x underneath the front panel.

Disconnect the SCSI / SAS, SCSI ID and power cable and slide the mechanism out the front of the chassis.

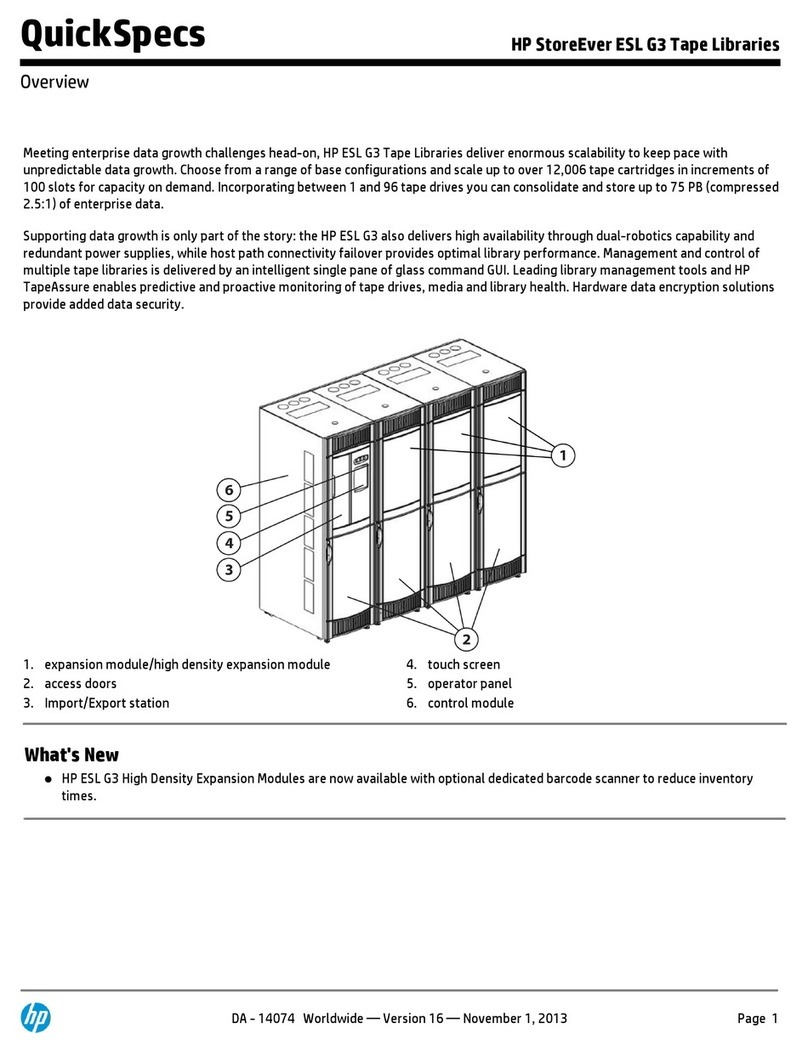

3.1.3 Remove the SCSI I/O PCA at the rear of the enclosure (SCSI enclosure only). Use a pair of small pliers to

unscrew the 4 x securing nuts at the rear of the enclosure –see image 1 below. The I/O SCSI PCA is > 10 square

cm’s and requires selective treatment. See images 1 & 2 below.

3.1.4 Disconnect the SCSI ribbon cable from the I/O PCA. Ribbon cable containsbrominated flame retardant and

requires selective treatment. See image 2 below.

3.1.5 Remove the SAS cable assembly (SAS enclosure only). Remove 2 x T-10 screws from the rear of the enclosure.

Remove 4 xsize ‘1’ crosshead screws to remove the clamp from the SAS PCA. The PCA is > 10 square cm’s –

see image 3.

3.1.6 Remove the Power Supply Unit (PSU) from the enclosure chassis. Remove 2 x T-10 screws fromthe rear –above

/ below AC inlet filter, and 1 x T-10 screw from front side of chassis. Remove 2 xcrosshead screws -one from the

front, one from the rear and slide the lid back towards the rear of the PSU –see image 4.

3.1.7 Remove the PSU and the on/ off PCA from their enclosure. PSU PCA is secured by 5 crosshead screws. 1 x

crosshead securing the on / off PCA. The PSU PCA is > 10 square cm’s. It also contains 5 x electrolytic

capacitors. The on / off PCA is > 10 square cm’s. See image 5.

3.1.8 Mechanism disassembly: remove the two wing brackets; remove the front panel (clip fit –two clips top, two

bottom), and remove the lid and the base. You will need to cut the 4 xtamper-proof tapes, top and bottom to clip off

the lid and the base.

3.1.9 Remove the main PCA. Disconnect all FFC / FPC connectors and 1 x cable connector. The main PCA is > 10

square cm’s. See image 6. When the PCA is removed, remove the PCA shield. Located underneath the main

PCAand secured by 2 x T-10 screws –see image 6.

3.1.10 Remove the CMWP PCA. Slide the cartridge assembly 2 cm back into the mechanism. Remove 5 x T-5 screws

securing the PCA and remove from mech. CMWP PCA is > 10 square cm’s –see image 7.

3.1.11 Remove the 2 x reel motor PCAs. Remove the tape reel. 3 x T-10 screws and cut the tape. Once removed,

remove 3 x T-8 screws securing the front reel motor PCA and 3 xT-8 screws securing the rear reel motor PCA.

Both reel motor PCAs are > 10 square cm’s.See image 8.

3.2 Optional Graphic. If the disassembly process is complex, insert a graphic illustration below to identify the items

contained inthe product that require selective treatment (with descriptions and arrows identifying locations).