HPS TruWave Active Harmonic Filter Quick Start Instructions

4

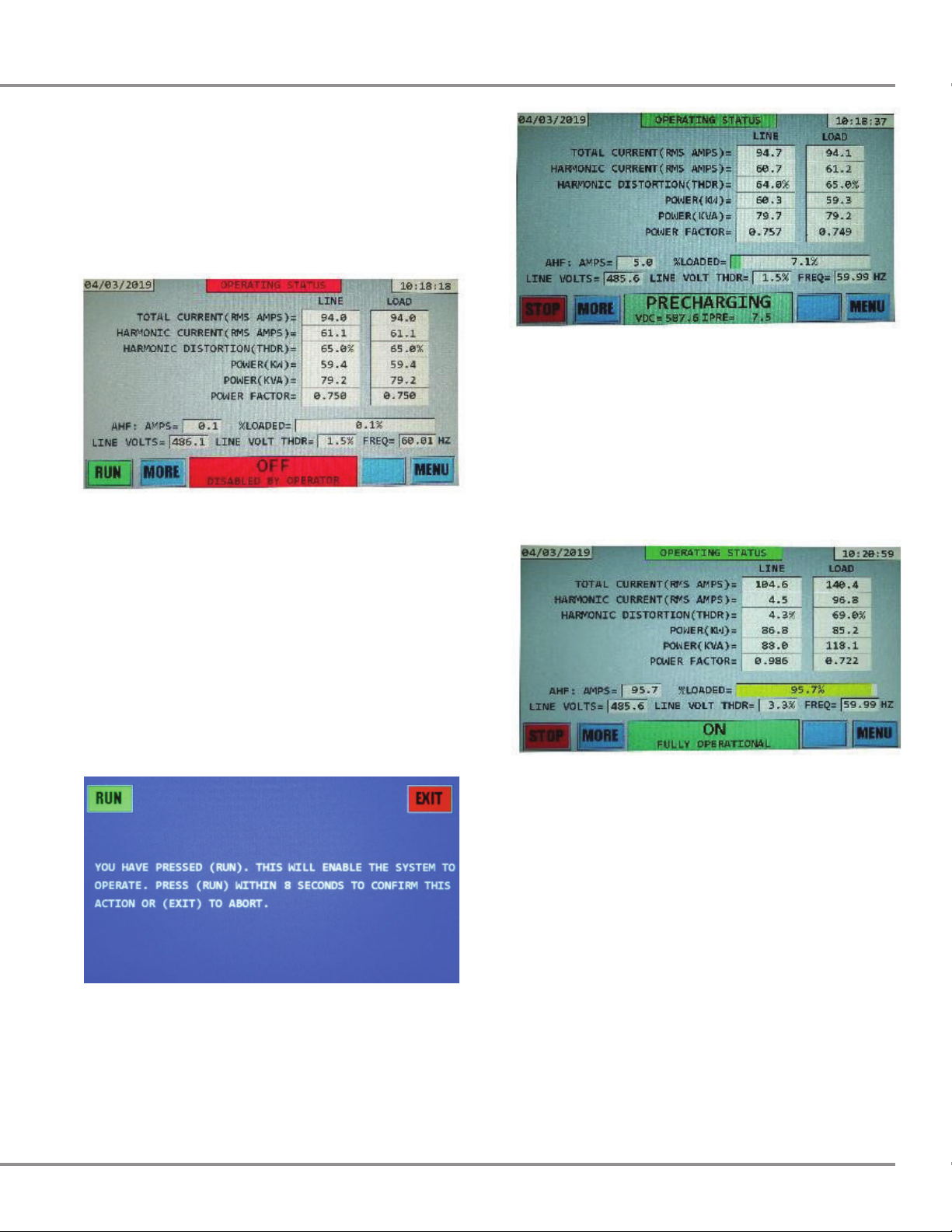

As stated before, your AHF has the capability to

automatically determine if your CTs are placed on the

correct phases and in the correct direction. However,

to do so, there must be some load operating. This load

cannot be too inductive or capacitive in nature – one

or more AC motor drives operating at 20% or greater

than the capacity of the active filter is an excellent load.

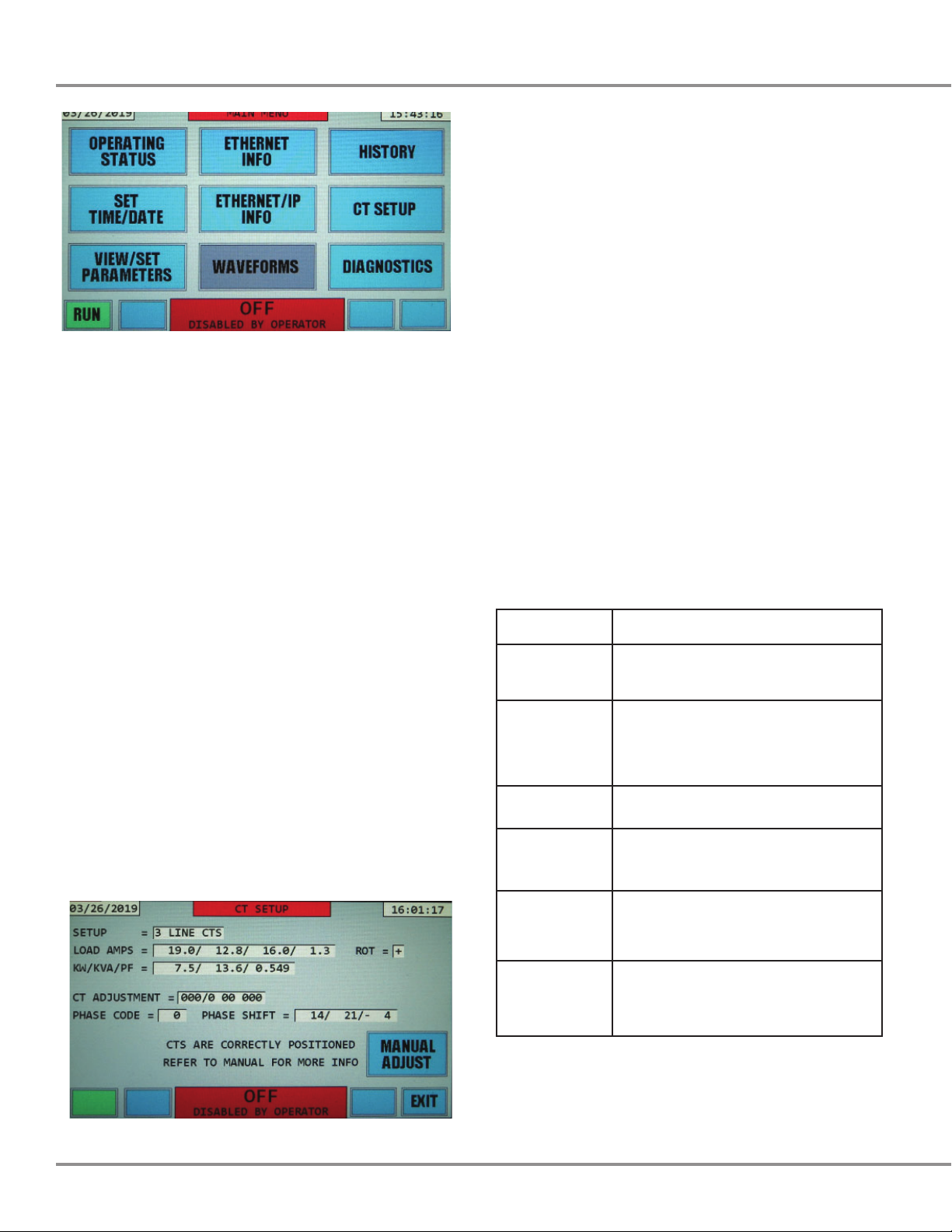

The first number in the 6th line is the “Phase code”.

This value will be “0” if your CTs are installed correctly.

A non-zero code between -28 and 43 indicates the CTs

are not on the correct phases and/or are in the wrong

direction. At this point if you see a value other than zero

you will need to refer to section 4 in the manual, tables

4.2 or 4.3.

If the message on the 7th line is “CTS ARE CORRECTLY

POSITIONED” or “CTS ARE CORRECTLY ADJUSTED”,

your CTs are on the correct phases for proper operation

and you can proceed to the next step.

If you observe any of the other messages in the following

table, refer to Table 4.1 of the manual for information on

how to correct the situation, and specifically go to the

subsection of section 4 shown in the following table for

the particular CT SETUP message displayed.

11. On the CT SETUP display, the 2nd line indicates how

many CTs the system is programmed for (2 or 3), and

whether the system is programmed for LINE or LOAD

side CTs. Verify that the number of CTs indicated and

the position (LINE or LOAD) agrees with the number of

physical CTs and location of those CTs you have wired

into your system. If not, you will need to either correct

your physical wiring to match the AHF configuration

shown, or change the AHF setup parameters. To

change these parameters, press the “MENU” button

on the display, followed by pressing the “VIEW/SET

PARAMETERS” button on the MENU display. Then refer

to sections 5.6, 5.6.2, and 5.6.7 to change the number

of CTs and/or position (Line or Load) of those CTs.

The 3rd line shows how much current is presently being

drawn by the load. The first 3 numbers, separated

by “/” characters are the 3 phases A, B, and C. The

4th number indicates the neutral current.The neutral

current is calculated by the AHF only for systems that

have 3 CTs.

The 4th line shows the present real power in KW and

apparent power in KVA, as well as the power factor of

the load.

The 5th line titled “CT ADJUSTMENT” indicates any

“programmed” adjustment that the AHF has been

set up for to compensate for CTs that are not placed

correctly.

CT SETUP

Message Explanation and Action to Take

LOAD CURRENT

TOO LOW

Insufficient load current to determine if

CTs are placed correctly. Go to subsection

4.1 in the owners’ manual to correct.

LOAD TOO

CAPACITIVE/

INDUCTIVE

Load current is high enough; however,

load is either too capacitive or inductive

to correctly determine if CTs are placed

correctly. Go to subsection 4.1 in the

owners’ manual to correct.

ERRONEOUS

PHASE CODE

Should not see this message. Stop and

contact factory if you do see it.

2 CTS ON A&C.

MUST BE ON A&B

When using 2 CTs, they must be located

on phases A and B. Go to subsection 4.2

in the owners’ manual to correct.

2 CTS ON B&C.

MUST BE ON A&B

When using 2 CTs, they must be located

on phases A and B. Go to subsection 4.2

in the owners’ manual to correct.

FIX CTS OR

ADJUST HERE

CTs are not on the correct phases and/

or are in the wrong direction. Go to

subsection 4.2 in the owners’ manual to

correct.

Your AHF also has the capability to automatically correct

for certain incorrect CT placements, without rewiring or

moving CTs. Refer to section 4.2.3. of the manual in order

to use this feature.