Table of Contents

1. Notes (Please be sure to read before using)··············································································1

1-1 Installation·····················································································································1

1-2 Connection of Connector··································································································1

1-3 Division of Micro step·······································································································1

1-4 Heat generation of a motor ······························································································· 1

1-5 Electric current value of Micro Step ····················································································1

1-6 Unipolar type motor drive ·································································································1

1-7 Compatibility notice to the customers using SD4030B2.··························································1

2. Specifications ·····················································································································2

3. Connector pin assignment·····································································································3

3-1 CN1·····························································································································3

3-2 CN2·····························································································································3

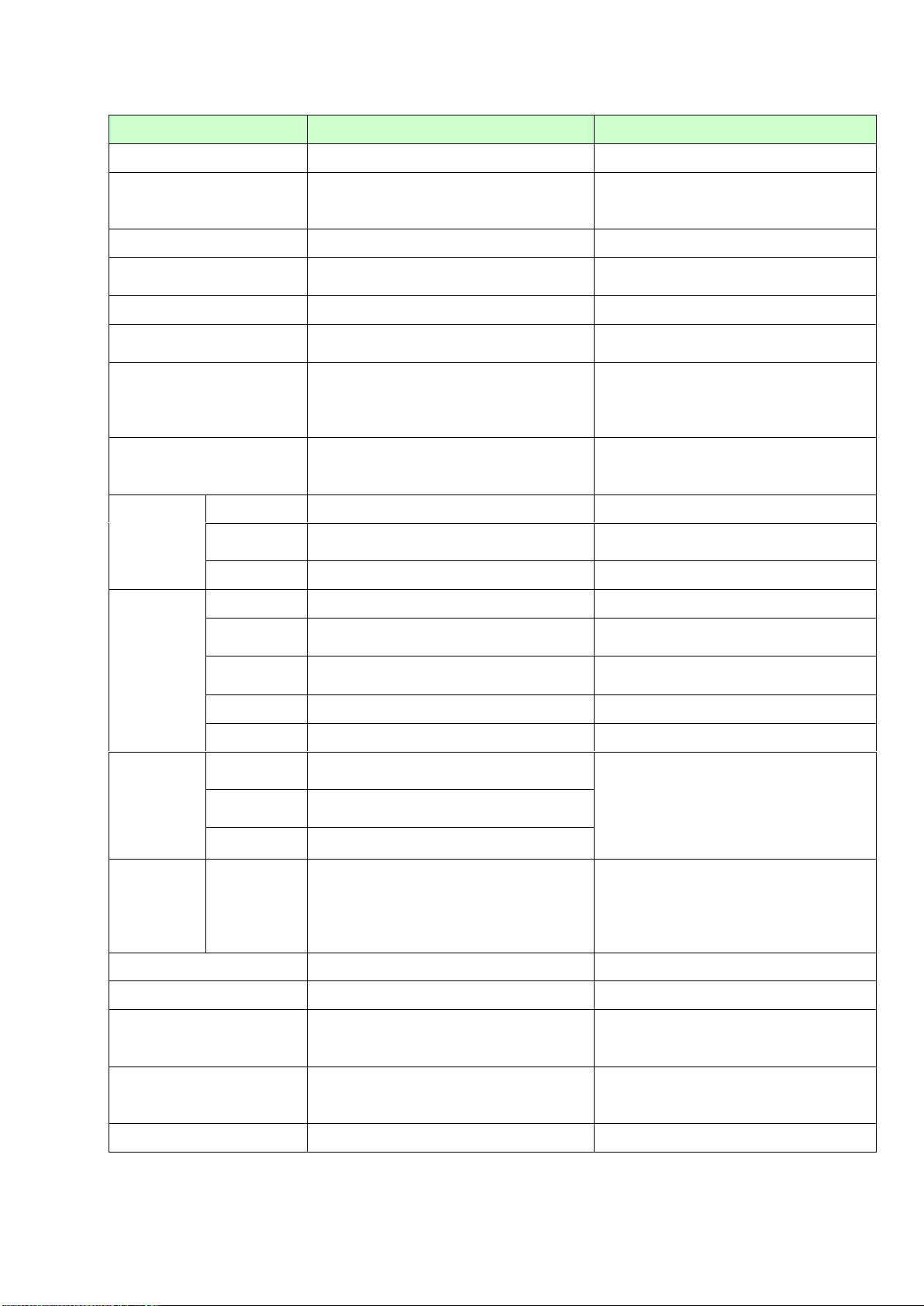

4. I/O circuit diagram················································································································4

4-1 Command pulse or CW pulse (P+, P-), Direction Command or CCW pulse (D+, D-) Input ·············4

4-2 Excitation off (OFF) input··································································································4

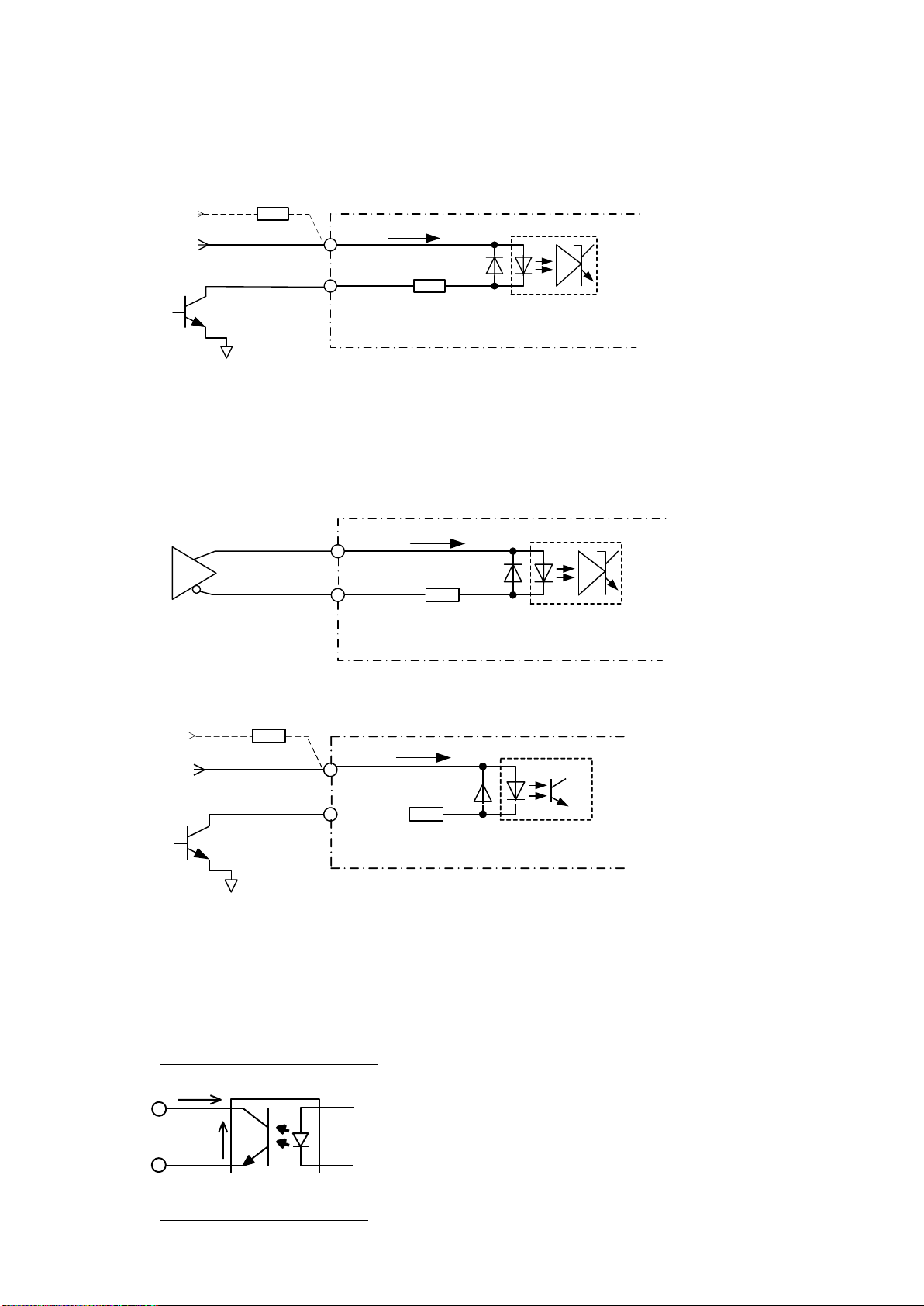

4-3 Alarm (ALM) Output·········································································································4

5. Logic of Command Input pulse·······························································································5

5-1 In case of 1-pulse mode···································································································5

5-2 In case of 2-pulses mode ·································································································5

6. Connection of Motor·············································································································6

6-1 In the case of Bipolar type motor························································································6

6-2 In the case of Unipolar type motor······················································································ 6

7. Setting of switch SW 1··········································································································7

8. Setting of switch SW 3(MIX) ··································································································8

9. Settings of Jumper JP1·········································································································9

10. LED“POW” ····················································································································· 10

11. JOG operation················································································································· 10

12. Setting of potentiometers··································································································· 10

12-1 RUN potentiometer······································································································ 10

12-2 STOP potentiometer·····································································································11

12-3 JOG potentiometer·······································································································11

13. How to adjust the RUN potentiometer precisely······································································ 12

14. Need of a rated output current reduction at a higher power supply voltage area···························· 12

15. Troubleshooting··············································································································· 13

16. Component layout············································································································ 14

17. Dimension······················································································································ 15

18. Difference between SD4030B2 and SD4030B3······································································ 16

18-1 Difference in how to set Mix Decay················································································· 16

18-2 Difference on the maximum frequency of Command pulse ·················································· 16

19. CE Marking····················································································································· 17

20. Caution for ESD damage··································································································· 17