7www.htc-oorsystems.com

HTC D60

V 1.0

2. Introduction

2.1 General information

Together with HTC's oor grinders, HTC's dust extractor is designed to create as dust-free environ-

ment as possible in conjunction with the dry grinding of stone and concrete oors. The dust sucked

up is collected in, for example, a bag system.

Read the manual carefully so that you know how to use and maintain the dust extractor before using

it. Contact your local retailer for further information. For contact information, see Contact Information

at the start of the manual.

2.2 Liability

Even though every effort has been made to make this manual as complete and accurate as possi-

ble, we bear no responsibility for incorrect or missing information. HTC reserves the right to change

descriptions in this manual without giving prior notice.

This manual is protected by the Copyright Act and no part of it may be copied or used in any other

way without the written approval of HTC.

2.3 Manual

In addition to general functions, this manual contains information on areas of use and care of the dust

extractor.

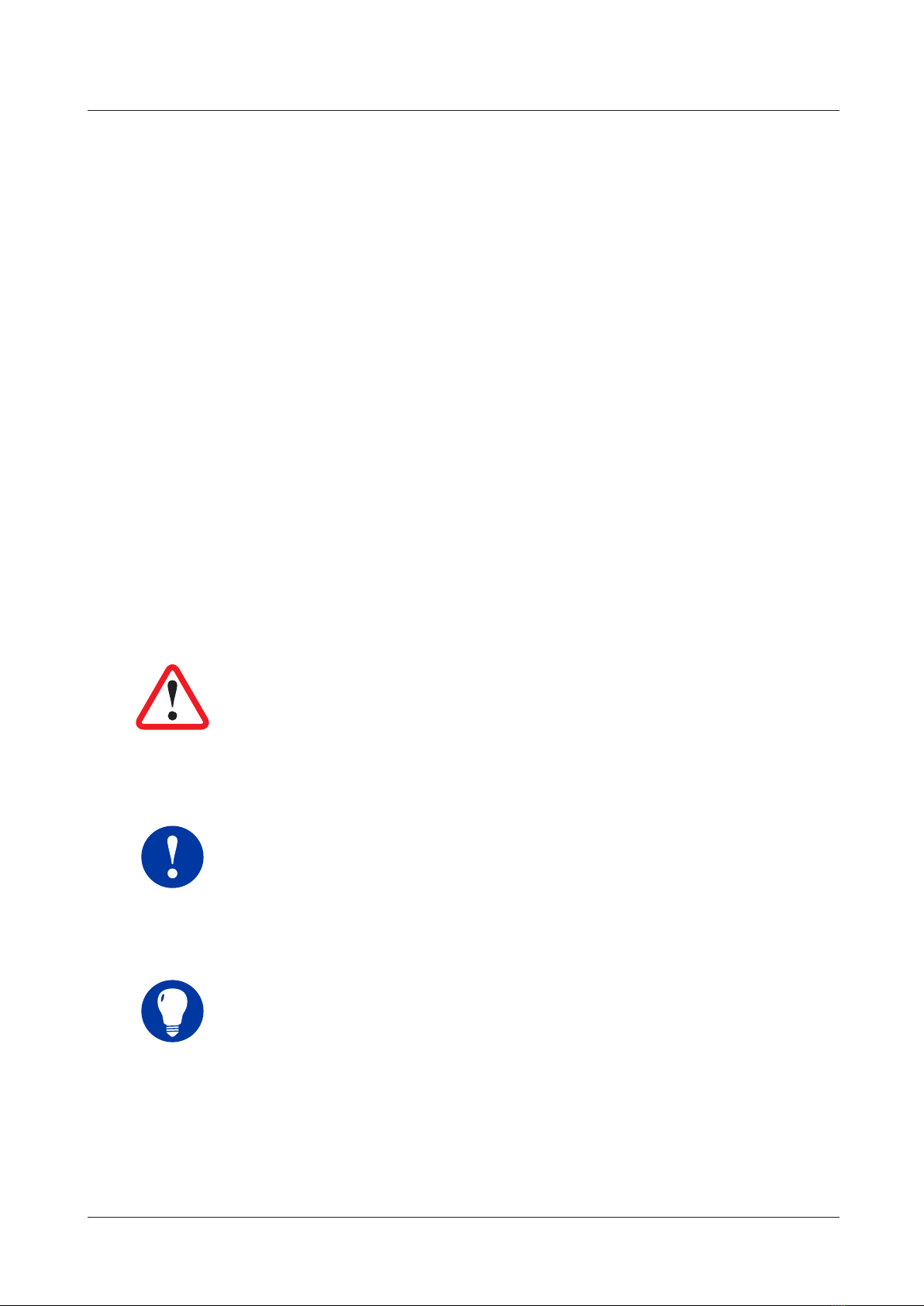

Safety Instructions – Explanation of Symbols

The following symbols are used in the document to indicate where special attention is needed.

Warning!

This symbol means Warning! and indicates a risk of personal injury or material

damage in the event of incorrect use of the dust extractor. If you see this symbol

next to a section of text, you must be particularly careful when reading through

the text and not carry out any stages of which you are unsure. This is for your own

and other users’ safety and to avoid damage to the dust extractor.

Note!

This symbol means Note! and indicates a potential risk of material damage in

the event of incorrect use of the dust extractor. If you see this symbol next to a

section of text, you must be particularly careful when reading through the text and

must not carry out any stages of which you are unsure. This is to avoid damage to

the dust extractor.

Tip!

This symbol means Tip! You can get tips and advice on ways to make operating

your dust extractor easier, and ways to avoid wear. When you see this symbol you

should read the accompanying text to facilitate your work and prolong the service

life of the dust extractor.