4B

A

Specications HTO-100 HTO-150 HTO-200 HTO-250 HTO-300

Salt Used - Per Regeneration 6.0 lbs 9.0 lbs 12.0 lbs 15.0 lbs 18.0 lbs

Water Used - Regeneration 86.4 gal 148 gal 162.4 gal 216.0 gal 224.8 gal

Hardness Removal - Grains 25,000 37,500 50,000 67,500 75,000

Tank #1 Carbon Quantity (ft3) 1.0 ft 1.50 ft 2.0 ft 2.5 ft 3.0 ft

Tank #2 Resin Quantity (ft3) 1.0 ft 1.50 ft 2.0 ft 2.5 ft 3.0 ft

Tank Size 9x48 10x54 12x52 13x54 14x65

Tank Jacket / Media Loaded Yes Yes No No No

BrineTank (Inches)

BTR 18.1 x 34.5

BTS 15.0x34.7

BTR 18.1 x 34.5

BTS 15.0x34.7 20.3 x 37.4 20.3 x 37.4 23.0 x 40.5

Salt Storage Capacity

BTS 240 lbs BTR

270 lbs

BTS 240 lbs BTR

270 lbs 350 lbs 350 lbs 420 lbs

Flow Rate @ 15 psi Pressure Drop 7.2 gpm 7.4 gpm 9.0 gpm 9.2 gpm 9.2 gpm

Flow Rate @ 25 psi Pressure Drop 10.0 gpm 10.1 gpm 11.9 gpm 12.1 gpm 12.1 gpm

BackWash Flow Rate 4.0 gpm 5.0 gpm 7.0 gpm 8.0 gpm 10.0 gpm

ShippingWeight 154 lbs 171 lbs 214 lbs 225 lbs 232 lbs

RegenerationType Up Flow

Plumbing Connections 89 Model 1”Straight NPT. 785 Model 3/4”900Elbows & 1”Straight NPT

ResinType Aquane 8% cation exchange resin

CarbonType Catalytic Carbon

Electrical Requirements Input 120V 60 Hz - Output 12V 650mA

WaterTemperature 40°F and 110°F (4°C - 43°C)

Water Pressure Min. 30 - Max. 125 psi

SPECIFICATION

Working Temperature:This unit must be

operated at temperatures between 40°F and

110°F (4°C - 43°C).

Working Pressure:This water softener

must be operated on pressures

between 30 psi to 125 psi. If the water

pressure is higher than 125 PSI, use a

pressure reducing valve in the water supply

line to the softener.

Voltage = 120V / 60 Hz

Pipe Size = 3/4” and 1”

• At the stated service flow rates, the

pressure drop through these devices will

not exceed 15 psig.

• The manufacturer reserves the right

to make product improvements which

may deviate from the specifications

and descriptions stated herein, without

obligation to change previously

manufactured products or to note the

change.

* Do not use water that is microbiologically

unsafe without adequate disinfection

before or after the system.

Peak flow rates intended for intermittent

use only (10 minutes or less) and are for

residential applications only. Do not use

peak flow rate for commercial applications

or for a continuous rate when treated

water supplies are geothermal heat pump,

swimming pool, etc.

For satisfactory operation, the pumping rate

of the well system must equal or exceed

indicated backwash flow rate.

All units come with plastic bypass

Maximum Iron = 1.5 ppm

Maximum Hydrogen Sulde = 0.0 ppm

Maximum Manganese = .75 ppm

pH = 6.5 to 8.5

Models A (Inches) B (Inches)

HTO-100 58 9

HTO-150 64 10

HTO-200 62 12

HTO-250 64 13

HTO-300 75 14

SYSTEM DIMENSIONS

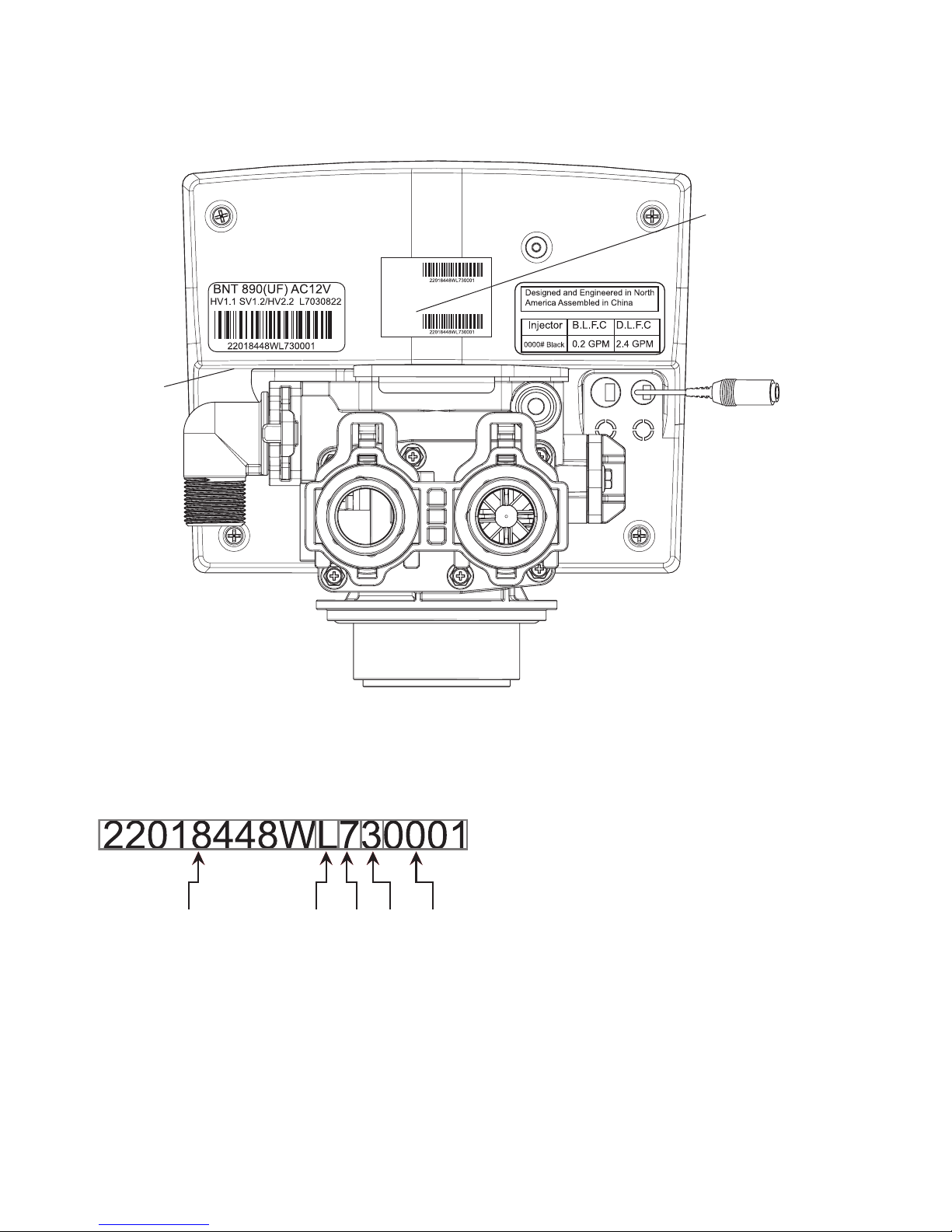

All units are factory programmed to the below specifications. Alteration should only be done by a factory trained technician or after consultation with one of our technical

representatives if you have any questions please call 877-288-9888.