lp-220 Rev. 000 Rel. 007 Date 2.12.18

5

C. Terminology

Solar terminology diers from region to region. To avoid confusion,

please note the following:

Supply – The plumbing line running from the outlet of the collector

to the tank.

Return – The plumbing line running from the tank (or heat

exchanger) to the inlet of the collector. This line incorporates the

circulation pump.

Insulation - Solar radiation level, expressed in kWh/m2/day or Btu/

ft2/day.

D. Possible System Designs

1. Open Loop Systems

An open loop system has potable water circulating through

the solar collectors. Open loop systems are recommended for

hot or warm climates that rarely freeze. For rare incidents when

ambient temperature drops below freezing, the controller can

be programmed to provide freeze protection by circulating warm

water from the tank through the solar collectors.

For open loop systems, the normal operating pressure should be

less than 72.5 psi. This operating pressure is provided via use of

a pressure limiting/reduction valve on the main supply line. An

expansion tank is required in open loop systems.

An open loop system may allow the solar collectors to stagnate to

prevent overheating of the storage tank. In the event of component

failure, the pressure relief valve must be able to release the

increased pressure, and should be rated to meet the maximum

possible pressure output of the solar collector(s). Please see Part 3

for sections regarding overheating.

2. Closed Loop Systems

A closed loop system uses non-potable heat transfer uid (HTF)

and must be pressurized to less than 72.5 psi. Closed loop systems

require an expansion tank to accommodate HTF expansion. The

system should be designed to minimize stagnation after tank

temperature has been met; extensive stagnation may increase pH

levels and glycol deterioration.

The expansion tank and plumbing must be properly sized so that

the safety pressure relief valve will not activate except in the event

of component failure or extreme conditions. The pressure release

must be set at no more than 113 psi. (There may be exceptions in

engineered designs for tall buildings.)

3. Drain Back Systems

The drain back method provides eective overheating and freeze

protection, making these systems well-suited for all climates.

When storage tank water temperature settings are reached or the

collector temperature falls below a set temperature, the pump shuts

o, allowing the HTF to drain back into the tank. Some drain back

systems use potable water as HTF. Others use a propylene glycol /

potable water mix.

Drain back systems require larger pumps to move HTF up and into

the solar collectors. Mounting the drain back tank as high as possible

within conditioned space will reduce pump size.

For drain back systems, the solar loop often operates at less than

25 psi, far lower than open or closed loop systems. These low

operating pressures do not require an expansion tank. A pressure

relief valve, installed on the drain back tank and piped in copper to

an appropriate drainage location, will provide sucient expansion

protection. This pressure relief valve and drain outlet pipe must

never be sealed or blocked. The pressure relief valve is intended to

be operated for safety purposes only.

NOTE: Supply and return connections to the collector must use

eccentric ttings or a tting arrangement that allows full draining

of header pipes. The collector or array should be mounted with a ¼”

pitch towards the supply port to facilitate the drain back process.

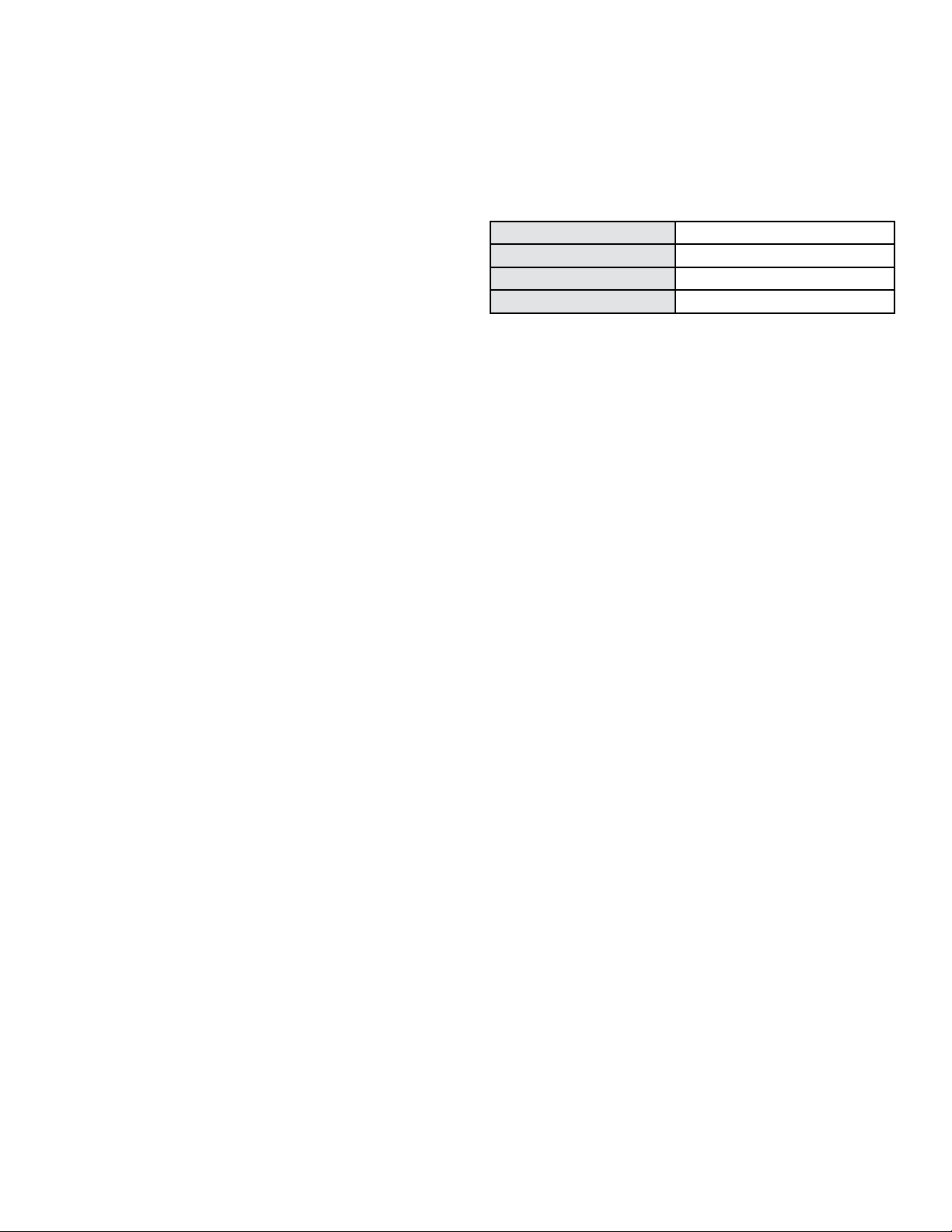

E. Fluid Quality

Water quality is very important. Water in direct ow through the

solar collectors must rst meet potable water requirements; any uid

circulated through the collectors should be non-corrosive to copper. In

addition, water quality must meet the following requirements.

Total Dissolved Solids < 500 ppm

Total Hardness < 7 grains (120 ppm)

Chlorides < 100 ppm

pH Levels 6.5 - 8.5

Table 1 - Water Quality Requirements

In areas with “hard” water (water hardness greater than 120 ppm)

where open loop format is used, lime scale may form inside the solar

collector. Scale deposits will reduce collector eciency and eventually

plug the collectors. In such regions, it is advisable to install a water

softening device to ensure the long term ecient operation of the

collector, or consider a closed loop system.

In order to meet health and safety regulations, glycol used should be

food grade propylene glycol, FDA rated as “generally recognized as

safe” (GRAS). If using a glycol / potable water mix, the water must meet

the above requirements. The glycol content of the liquid must not

exceed 50%, unless the manufacturer species that a dierent ratio

is recommended for use with solar water heaters. Glycol should be

checked periodically to prevent it from becoming acidic. Please refer

to guidelines provided by the glycol manufacturer regarding glycol

maintenance.

In addition, collector plumbing should slope toward the drain back

reservoir at ¼” per foot minimum to facilitate the drain back process.

If continual slope is not achievable, consider a pressurized closed loop

system.

F. Corrosion

Both copper and stainless steel are susceptible to corrosion when,

amongst other factors, high concentrations of chlorine are present.

The solar collector may be used for heating of spa or pool water, but

levels of free chlorine must not exceed 5 ppm. Otherwise, the copper

header could corrode.

NOTE: HTP DOES NOT WARRANT THE SOLAR COLLECTOR AGAINST

CORROSION-RELATED DAMAGE.

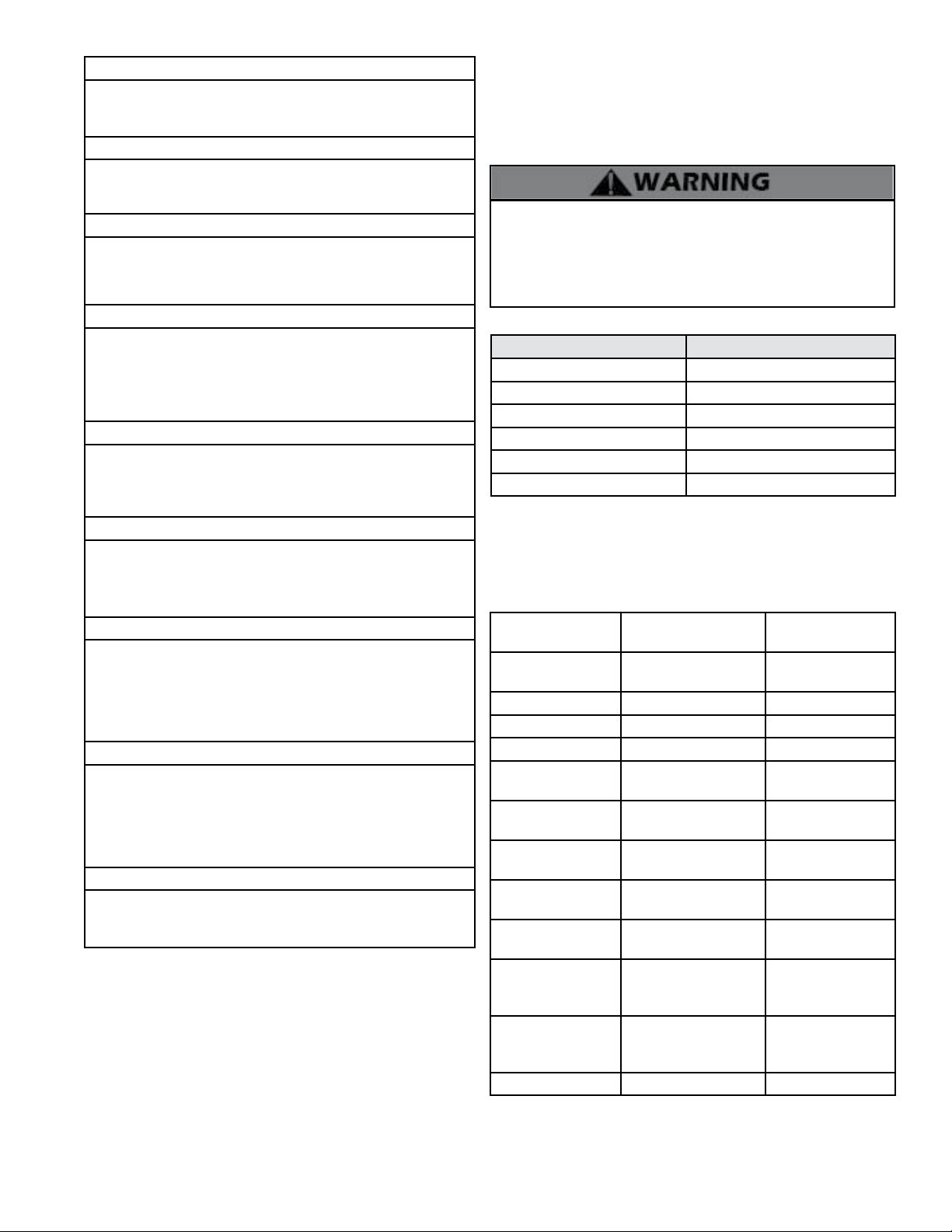

G. Freeze Protection

Freeze protection must be implemented in any regions that may

experience freezing conditions at any time throughout the year.

“Freeze tolerance limits are based upon an assumed set of

environmental conditions. Extended periods of cold weather, including

ambient air temperatures below the specied limit, may cause

freezing in exposed parts of the system. It is the owner’s responsibility

to keep the system’s freeze protection levels maintained in accordance

with the supplier’s instructions if the air temperature is expected to

approach the specied freeze tolerance limit.”

Open or closed loop systems: In areas with temperatures not falling

below 23oF, a dierential solar controller with freeze protection may

be used (e.g. requiring pump to circulate if the manifold temperature

approaches freezing). In an open loop system, a freeze valve (which

opens to allow water to dribble out) could also be considered.

Closed loop systems: In areas with temperatures falling below 23oF, a

propylene glycol / potable water mix should be used to provide freeze

protection. Please refer to glycol manufacturer’s specications about

the temperature ranges the liquid can withstand. Only food grade

propylene glycol, FDA rated as GRAS, should be used.

NOTE: HTP DOES NOT WARRANT THE SOLAR COLLECTOR AGAINST

FREEZE-RELATED DAMAGE.

H. Wind Stress

When installing the collector, please consider the issue of wind