2

Foreword

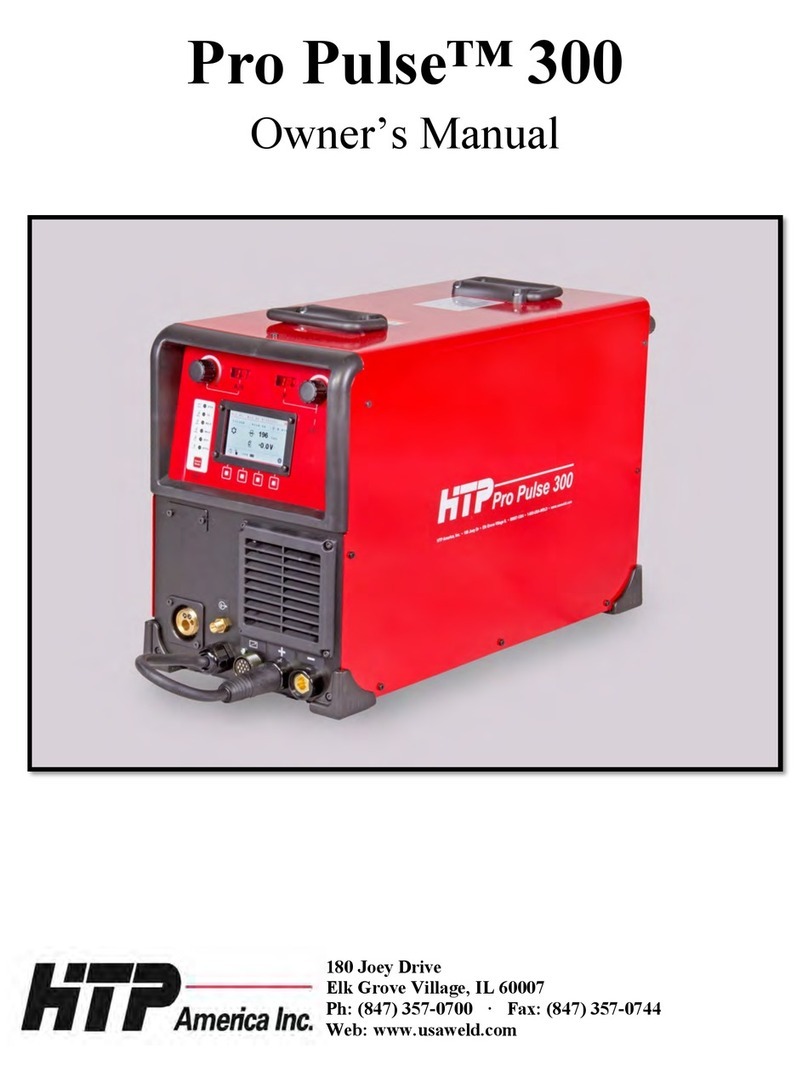

Thank you for purchasing a new HTP® Inverter MIG welder. This manual covers the HTP MIG 200i, the HTP MTS 210,

and the HTP Pro Pulse™ 220 MTS. All three welders feature HTP’s advanced one knob Synergic Control. The MIG 200i

is an analog, full synergic welder with an Easy Set feature. The MTS 210 is an advanced, multi-process, full synergic

welder with a digital LCD. The Pro Pulse 220 MTS is our advanced, multi-process, full synergic, pulse MIG welder. The

Pro Pulse 220 MTS produces high quality, virtually spatter free welds on all common metals when you use the correct gas

and consumables for your welding application. By following the instructions closely, you can achieve success when

welding with the Pro Pulse 220 MTS, even when welding aluminum where the margin of error is very small (when

welding aluminum, almost everything must work out just right in order to achieve good results). This does not mean that a

novice welder will not be able to perform aluminum welds successfully with the Pro Pulse 220 MTS. No matter your skill

level, the more knowledge you have about the operation of your HTP welder and the specific welding processes, the more

likely you are to produce professional results. HTP provides this manual and some videos to familiarize and help you

weld successfully with your new HTP welder.

Customers interested in the Pro Pulse 220 MTS often ask us the following questions: If I buy the Pro Pulse 220 MTS, will

I be able to weld aluminum right out of the box? and Why do some customers find welding with the Pro Pulse 220 MTS

difficult? Why do some customers, including customers with decades of regular MIG welding experience, struggle when

welding with the Pro Pulse 220 MTS, even after reading the entire manual twice and watching several videos? First,

many of our customers successfully weld aluminum with the Pro Pulse 220 MTS within hours, not days. Second,

experienced welders struggle when welding with the Pro Pulse 220 MTS for multiple reasons, including the following:

Muscle Memory. Operators who typically MIG weld steel are accustomed to holding the gun close to the work piece,

and the frying bacon sound the machine makes when welding. Operators may be thrown off by the sound the Pro

Pulse 220 MTS makes when welding, and muscle memory causes the operator to keep the gun too close to the work

piece when welding aluminum, which requires a 3/4” to 1” CTWD (contact tip to work distance).

Old Habits and Frugalness. For aluminum welding (all spray arc transfer and pulse), your gas flow rate must be

significantly higher than for classic MIG welding (steel). Flow rates must be set between 35 and 50 CFH. We also see

operators running economy Asian import wire or random wound wire. For aluminum welding, where everything must

be just right, a bad roll of wire can make a bad day in aluminum welding. We recommend using a high-quality wire.

Currently, HTP sells Alcotec wire, which is a premium quality, precision wound wire that is made in the U.S.A. We

found that Alcotec wire works best with the Pro Pulse 220 MTS. We do not recommend using 1 lb., 4” diameter

spools.

Unrealistic Expectations. No matter what, MIG welds will never look identical to TIG welds. Although, when the

settings on your machine and the movement of your hand are in perfect harmony in a double pulse program, they can

come pretty close.

Also, when everything works right, welding aluminum is a lot like welding steel, though there are a few differences—

from the gas, to the MIG welding gun, to the consumables, to consumable use. When welding aluminum, even a

skilled welder may go through a few contact tips before finishing a roll of wire; unlike when welding steel, where

some operators can weld an entire 30 lb., 12” diameter spool of wire with one tip. Aluminum requires more contact

tips because it is welded in spray transfer, where it is more likely to burn back into the tip because of high heat. As a

novice welder, you may go through five to ten contact tips in the first few hours or the first day.

Birds nesting is not an issue with the Pro Pulse 220 MTS. However, burn back may occur and must be addressed

immediately—failure to do so will result in EXCESSIVE tip usage! When burn back occurs, the damaged tip

becomes useless and must be replaced. Furthermore, run about 10’ of wire through your MIG gun to discard any wire

damaged by slipping in the drive roll (which occurs due to burn back into the contact tip).

Material Thickness Rating Displayed in the Machine. We designed this feature to give you an idea about settings

(wire speed and voltage). The ratings displayed, generally speaking, are designed for straight line, push or pull

(depending on the application) welds, made at a rather fast travel speed (to reduce heat input and distortion) and

without any gun manipulation (no weaving, swirly motion, etc.). However, depending on the joint configuration (butt,

lap, or t-joint) and on the welding position (flat, horizontal, vertical up or down, and overhead), you need to adjust the

synergic settings accordingly.

Now, with a better understanding of what you will experience when welding with the Pro Pulse 220 MTS, read the rest of

the manual and watch the accompanying videos for a more thorough explanation of the machines’ features.