5

For more information, refer to the following standards and comply as applicable.

1. ANSI Standard Z49.1 SAFETY IN WELDING AND CUTTING, obtainable from the American

Welding Society, 2051 NW 7th St., Miami, FL 33125.

2. ANSI Standard Z87.1 SAFE PRACTICE FOR OCCUPATION AND EDUCATIONAL EYE

AND FACE PROTECTION, obtainable from American National Standards Institute, 1430

Broadway, New York, NY 10018.

3. America Welding Society Standard A6.0 WELDING AND CUTTING CONTAINERS WHICH

HAVE HELD COMBUSTIBLES, obtainable from same as item 1.

4. NFPA STANDARD 51. OXYGEN-FUEL GAS SYSTEMS FOR WELDING AND CUTTING,

obtainable from the National Fire Protection Assoc., 470 Atlantic Avenue, Boston, MA 02210.

5. NFPA Standard 51B. CUTTING AND WELDING PROCESSES, obtainable from same as item

4.

6. CGA PAMPHLET P-1. SAFE HANDLING OF COMPRESSED GASES IN CYLINDERS,

obtainable from the Compressed Gas Association, 500 Fifth Avenue, New York, NY 10036.

7. OSHA Standard 29 CFR, Part 1910, Subpart Q WELDING, CUTTING AND BRAZING.

Electrical Connection

Your Pro Pulse 200 operates on single-phase, 230 volt power (208-240 volt). The machine will draw 35

amps out of the wall when operating at a welding output of 200 amps. If the machine is operated on a

generator, it needs to be a clean power generator with a minimum of 8500 watts.

General Characteristics

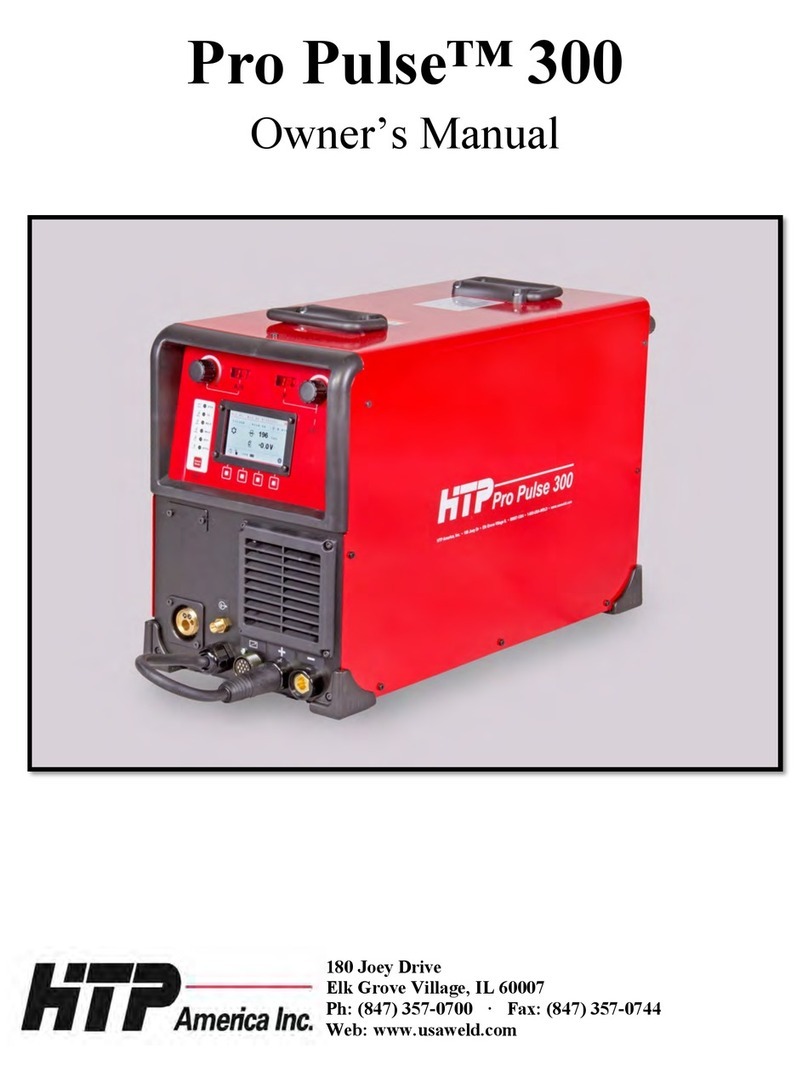

Our new pulsed process welding machine, which features electronic adjustments controlled through a

microprocessor, allows the operator to achieve excellent welding quality, thanks to the advanced

technologies applied. The microprocessor circuit controls optimize the transfer of the arc, irrespective of

the load variation and of the impedance of the welding cables.

This machine is a synergic welding machine.

The key feature of a synergic welding machine is the ease of set up. In the past, charts from the wire

manufacturers were needed to determine wire speed and voltage, as well as CTWD (contact tip to work

distance) of different welding applications, which ultimately determined the arc length and also indicated

which shielding gas to use. With the Pro Pulse 200, this information is preprogrammed, readily available,

and displayed to the operator. The Pro Pulse 200 features an LCD display that allows the operator to select

a synergic program for a specific wire, such as steel, aluminum, stainless steel, silicon bronze, etc. Once

the operator selects a program, the machine tells the operator which gas to use and then allows the operator

to select the thickness of the material being welded. After selecting the synergic program and the material

thickness, the machine will automatically set the correct wire feed speed (IPM) and the matching voltage

to achieve the best welding results. Of course, since a lot of operators encounter different situations,

especially during repairs on used or dirty metal, the Pro Pulse 200 also gives the operator the option to

adjust the weld colder or hotter by increasing or reducing the voltage.

The Pro Pulse 200 also offers, as the first in its class, ST-arc. The ST-arc function reads welding

parameters back to the welding machine live (while welding). The function monitors the arc length and

keeps the arc length constant, while allowing the stick-out (contact tip to work distance) to vary. ST-arc,

essentially, allows the new welder to focus on the location of the weld, as well as the travel speed, and

also allows the experienced welder to keep a perfectly uniform weld bead and uniform heat input, which