7

Fig 13 shows a typical rear quarter panel, with 5 main areas for

spot welding. As mentioned above, paint is an electrical

insulator. Each main spot weld area has one spot weld circled.

It is necessary to have FOUR CLEAN SIDES OF METAL in

each circled area. The first spot weld in each area should be

where you have four clean sides of metal. Once that spot

weld is in place, it is only necessary to remove paint from

panel/vehicle in the area where the electrodes will contact.

Paint or weld through primer can be present on the mating

surfaces of the panel/vehicle, since the welder will now

establish a ground through the first spot weld, which was made

through the four clean sides of metal. However, for optimum

results it is storngly advised to remove the any paint, under-

coating, or sealant from between the two panels. These

contaminents could effect the quality of the weld nugget.

A good tool for paint removal is a fibertex abrasive pad.

The second spot weld should be placed next to the first as

opposed to the other end of the panel. This way, the electricity

has to flow a shorter distance to the first weld which is

providing the ground. The third spot weld should be placed

close to the second, and so on. However, the welds should not

be placed closer than 3/4” together.

In the “REST” Position, the welding lever is fully up, and the

spot welding arms are completely open. As you compress the

welding lever, the jaws begin to close. When the electrodes

touch, the compression cycle begins, however, the welding

current has not yet started. Further compression of the welding

lever will force the end of the welding lever to contact the micro

switch and start the welding current. You will hear the

transformer hum and feel your Quick-Spot vibrate as the

welding current is activated. The timer will automatically stop

the welding process. Maintain pressure on the Welding lever

for 1 to 2 seconds more to allow the welding nugget to solidify.

In order to operate properly, your Quick-Spot must transfer the

welding current from the bottom spot welding tong, into the

bottom side of the lower panel, through the lower panel, into the

top of the lower panel, into the bottom of the upper panel,

through the upper panel, into top of the upper panel, and finally

into the top spot welding tong, completing the electrical circuit.

What this means is BOTH SIDES OF BOTH PANELS MUST

BE CLEAN TO ALLOW THE WELDING CURRENT TO

PASS THROUGH THEM. If they are not clean, then your

Quick-Spot will not work correctly.

We always advise you make sample spot welds to test the

strength of the spot weld. When pulling the two spot welds

apart, one should always tear a hole in one of the panels if the

spot weld is good and strong.

Testing the Welds

We recommend testing the spot welds with either scrap panels

from the vehicle which you are working on, or using test panels

which HTP has available. The test panels are 1" wide x 3" long

18-gauge steel and are available 25 pieces at a time.

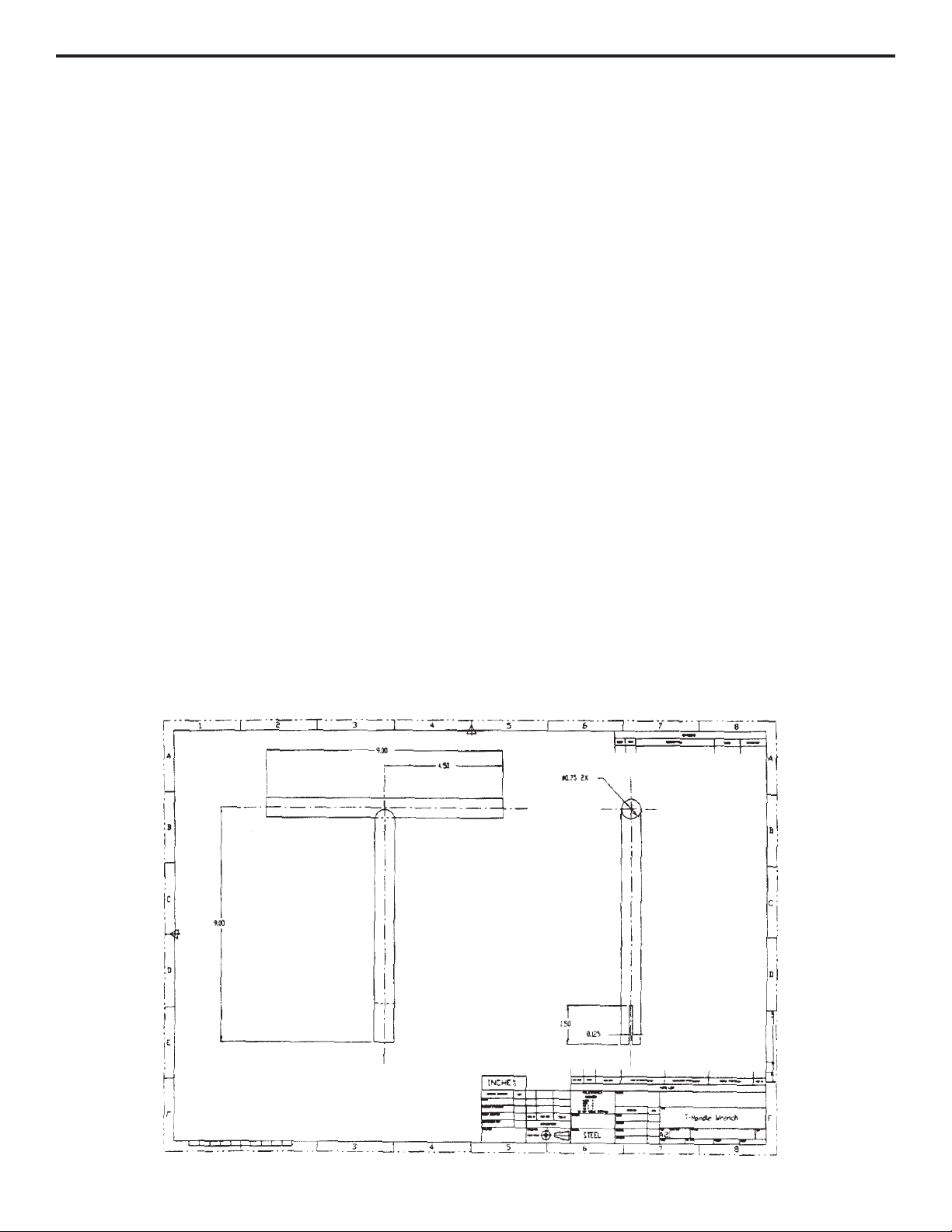

Fabricate a weld tester from the drawing below, or purchase a

67000-WT from HTP America. Mounting one of the panels in a

vice, and bend the other panel, so the weld tester can be rolled

around the panel like a sardine can. When rolled, a hole must

be pulled in one of the panels.

67000-WT HTP Spot Weld Tester