3

CAUTION

• The handpiece is designed for clinical dental use only.

• Always consider the safety of the patient when operating the handpiece.

• Check tip vibration outside the oral cavity before use. If any irregularities are found, discontinue use

immediately and contact your dealer.

• Do not force or pull on the power cord and/or handpiece cord. It could cause disconnection.

• Do not exceed recommended power ranges for the tips. Excess power may damage tooth structure

and/or result in damage to or excess wear of the tip.

• Check the tip before every use.Tips that have been bent, altered, worn or compromised in any way

should be removed from service.

• Do not use tips on metal or ceramic restorations, unless tips are intended specically for this purpose.

• Do not bend, alter or modify tips. Damage may occur to the tips affecting ultrasonic vibration.

• To eliminate risk of damage to the soft and hard tissues keep the tip moving at all times when in contact

with the tooth, gingiva, mucosa and intra-oral tissues.

• Conrm the threaded area of the tip is clean of all debris.

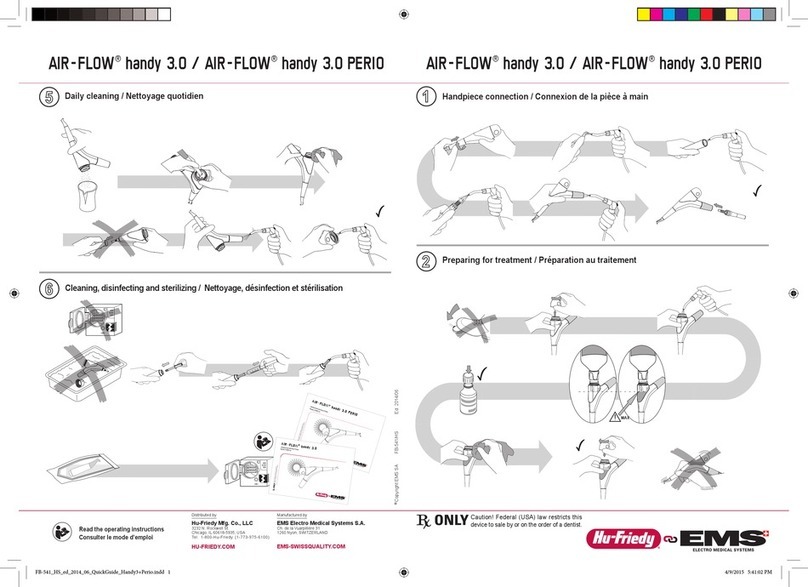

• To ensure proper tip vibration attach the tip securely to the handpiece with the Guardian wrench and

tip carrier. See gure 11.

• Attach the handpiece before turning on the power.

• Do not drop or otherwise expose the control unit to excess trauma.

• Use Hu-Friedy®Symmetry S-Series tips to ensure proper performance.

• Do not autoclave any parts unless indicated so in the User Manual.

• Sterilization by ultraviolet light may cause discoloration of the handpiece.

• If water is spilled on the irrigating pump cover, wipe thoroughly and allow it to dry completely prior

to use. If water gets inside the irrigating pump the rollers may slip and fail to pump irrigation solution.

• The system functions normally when the temperature is at 0˚-40˚C (32˚-104˚ F), relative humidity at

10-85% RH, atmospheric pressure at 500-1060hPa and no moisture condensation occurs in the unit.

Use outside of these conditions may cause malfunction.

NOTICE

• During vibration, the handpiece and the handpiece cord may affect computer and LAN cable. Noise

may be heard during operation near a radio receiver.

• Turn off the power switch after use. Remove the power plug and the water inside the control unit if not

used for an extended period of time.

• Users are responsible for operation control, maintenance and inspection.

• Store at -10˚-60˚C (14˚-140˚F), relative humidity at 10-85%RH, atmospheric pressure at 500-1060hPa.

Do not subject system to dust, sulfur or salinity.

• Contact dealer or Hu-Friedy Mfg. Co. if problems occur.