Danger!

Whenusingtheequipment,afewsafety

precautionsmust beobserved toavoidinjuries

and damage. Pleasereadthecomplete

operatinginstructions andsafetyregulations

withdue care.Keep thismanualinasafeplace,

so thatthe information isavailableat all times.If

you givethe equipmenttoanyotherperson,

hand over these operatinginstructions and

safetyregulations aswell.Wecannotaccept

anyliabilityfordamageor accidentswhich arise

due toafailuretofollowthese instructionsand

the safetyinstructions.

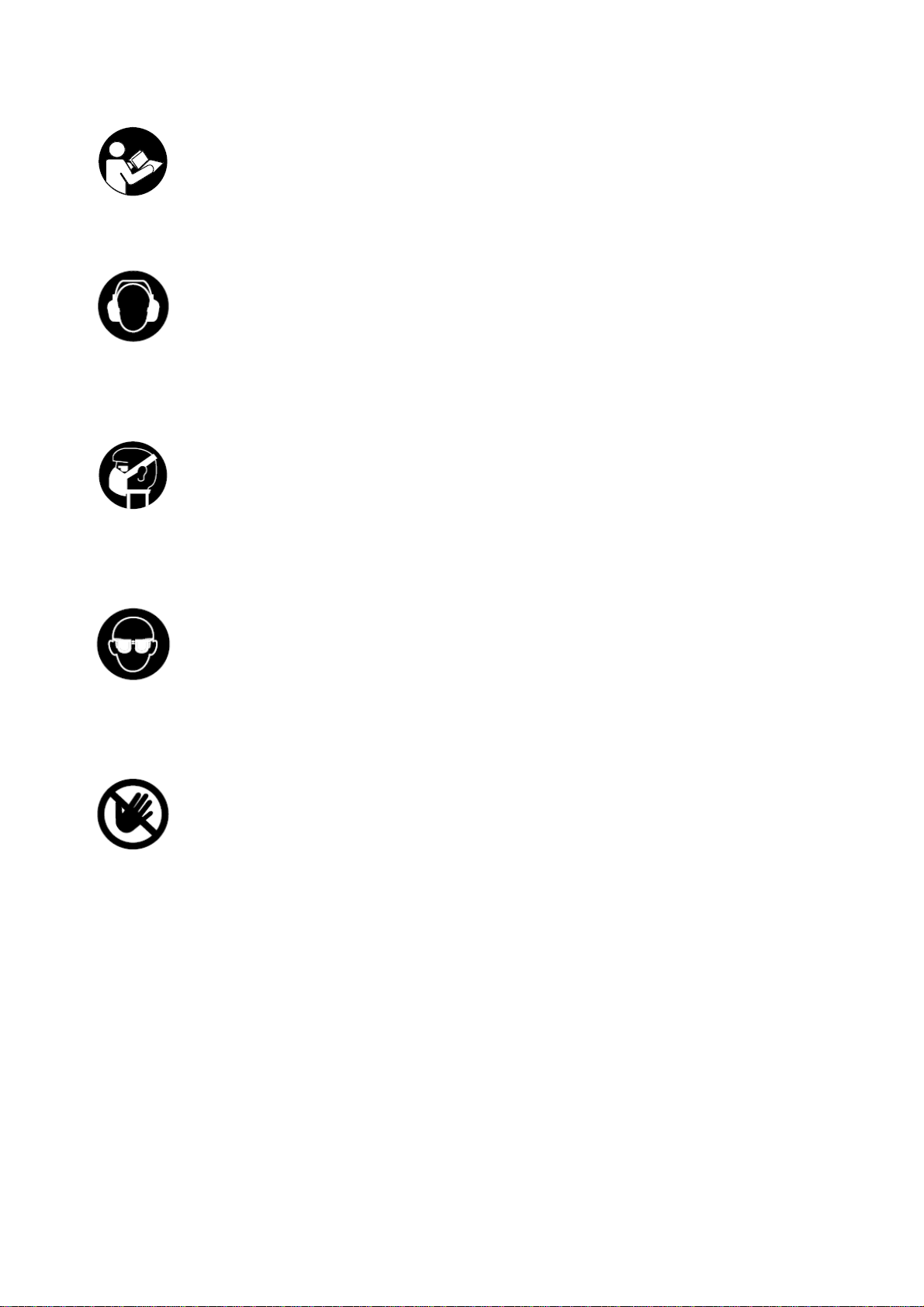

1. Safetyregulations

The corresponding safetyinformation can be

found inthe enclosed booklet.

Danger!

Readallsafetyregulationsand instructions.

Anyerrorsmadeinfollowingthe safety

regula-tionsandinstructions mayresult inan

electricshock, fi reand/or serious injury.

Keepallsafetyregulationsand instructions

inasafeplaceforfutureuse.

SAFE WORK

1.Keeptheworkareaorderly

Disorderinthe workarea canlead to

accidents.

2.Take environmentalinfluencesinto

account

Donotexpose electrictoolstorain.

Donotuse electrictoolsinadamporwet

envi-ronment.

Makesurethatthe workareais

well-illuminated.

Donotuseelectrictoolswherethereisa

risk offireor explosion.

3.Protectyourself fromelectricshock

Avoidphysicalcontactwithearthedparts

(e.g.pipes,radiators,electricranges,cooling

units).

4.Keepchildrenaway

Donotallowotherpersons totouch the

equipmentorcable,keep themawayfrom

your workarea.

5.Securelystoreunusedelectrictools

Unused electrictoolsshouldbestoredina

dry,elevated orclosed locationoutofthe

reach of children.

6.Donot overloadyourelectrictool

Theyworkbetterandmoresafelyinthe

specified outputrange.

7.Use thecorrect electrictool

Donotuselow-outputelectrictoolsfor

heavywork.

Donotusetheelectrictoolforpurposesfor

which itisnotintended.Forexample,donot

use hand-heldcircularsawsforthecutting of

branches or logs.

Donotuse theelectrictool tocut firewood.

8.Wearsuitableclothing

Donotwearwide clothing orjewellery,

which can becomeentangled inmovingparts.

Whenworkingoutdoors,anti-slipfootwear

isrecommended.

Tielonghairbackinahair net.

9.Use protectiveequipment

Wearprotectivegoggles.

Wearamaskwhen carryingout

dust-creatingwork.

10.Connectthedustextractiondevice if

you will beprocessingwood,materials

similartowood,orplastics.

Ifconnections fordustextraction and a

collect-ing device arepresent, makesurethat

theyareconnectedand used properly.

When processingwood,materialssimilarto

wood,and plastics.operation inenclosed

spaces isonlypermittedwiththe useofa

suit-ableextraction system.

11.Securetheworkpiece

Use the clamping devices oravice tohold

the workpieceinplace.Inthismanner,itis

heldmoresecurelythan withyour hand.

Anadditionalsupport isnecessaryforlong

work-pieces (table,trestle,etc.)inorderto

prevent themachine fromtipping over.

Alwayspresstheworkpiecefirmlyagainst