Preface

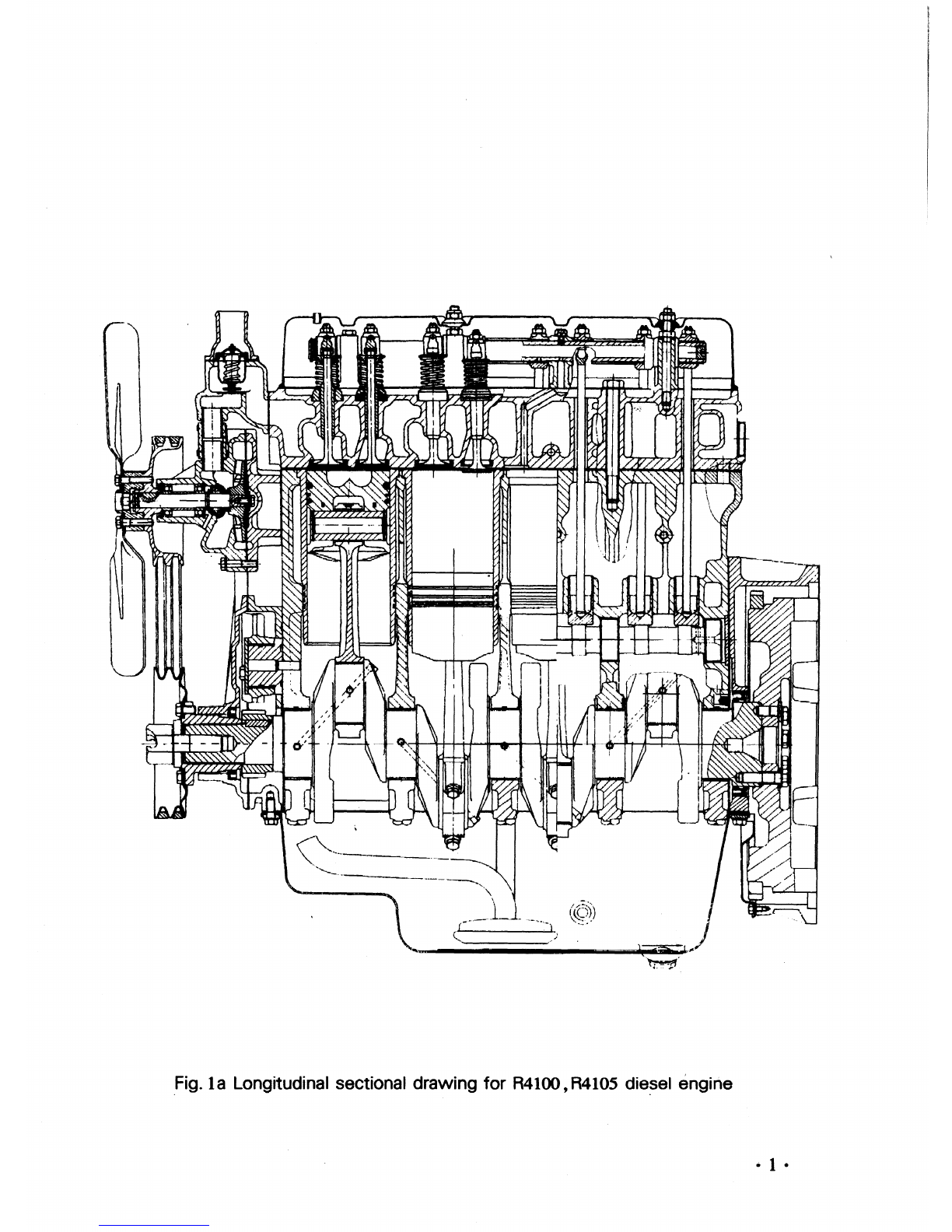

Rseries diesel engine is afour

~troke

,vertical, water-cooled,inline and direct injec-

ting combustion chamber type,high-speed diesel engine. Thjs series diesel engine is

specially designed for our country by Ricardo Consulting Engineers Co.

of

Britain,

and manufactured and developed firstly by Ricardo Consulting Engineers

Co.

cooper-

ated with Shandong Weichai Huafeng Power

Co.

,Ltd.

It's

a

new

generation prod-

uct instead

of

the same type diesel engine

in

our country. This type diesel engine

possesses performances

of

high power,economy and easy starting,under the envi-

ronment

with

temperature higher than

-lOOC

,the dieael engine can be easily started

without preheating. The first overhaul period is 8000hrs. Its reliability and service life

achieved aadvancde level among the same kind products all over the world.

Rseries diesel engine covers 8types

as:

both four-cylinder and six-cylinder

with

bore

of

lOOmm,both four-cylinder and six-cylinder with bore of

l05mm,and

every style

has

two

models of matural aspirated and superchareged.

RIOS

series is bore -en-

larged from Rl00 series,besides piston,piston ring,piston pin,cylinder liner,cylinder

liner seal ring and injection pump,

all

other parts

can

be exchanged between both

two

types of diesel engine.

Rseries diesel engine features easy adaptation

to

meet the various needs

of

matched equipments,according

to

the requirement of users. It can be furnished

with

hydraulic pump for Ifting and steering purposes, air compressor and vacuum pump

for breaking purposes and full power take-off from the front end

of

the crankshaft.

Through being changed for some

of

its parts accordingly, it can be used

to

match

with truck,tractor,small power generating station,engineering machinery,agricultru-

al

machinery,irrigation machinery,drilling machinery and so on. The output range

of

various version

of

Rseries diesel engine

is

35

KW

-125

KW

,its rated speed is 1500r/

min

-2800r/min.

The moder,its make-up rule and the meaning

of

the symbol for ev-

ery type is

as

follows:

R6100 Z D 1 2

(1)@@

@@@

(j)

CD:

distinguish symbol,Expressed

with

number sequence

~:

Version symbol,expressed

with

number sequence

@:

application featrue symbol,expressed

with

alphabet

no alphabet:for common usage;T: for tractor; G:for engineering machinery;

Q:

for vehicle;D:for generating

set;

C:for marine usage;P:for power take-off unit

@:

construction feature symbol,expressed with alphabet;no alphabet:for natural

#85-

pirated model;

Z:for

turbocharged model.

(S):cylingder bore(

mm)

@:cylinder number

(J):series symbol;stand for imported from RICARDO

This operating manual mainly introduces common usage type. For various versions;