7

3. Starting procedure

1), Connect the power supply and start switch, indicating light will light, then adjust

the speed-adjusting knob and all transmission parts start to run synchronously.

2), Micro-adjust the knob of embossing wheel to make that wheel swivel, after

getting a proper pressure, fix limiting screw.

3), Once turn the heating switch on, the green light of the electronic temperature

controller will light. According to the material and thickness of the packing bag,

adjust the temperature controller to the temperature required, then set the

position of heating knob of ink roller. Once the heating blocks and ink roller

heating block begin to preheat, Once the heating blocks and ink roller heating

block begin to preheat, the machine needs to be started meanwhile and kept

running at low speed.

4), That whether it is necessary to turn on the fan for cooling depends on the

material and thickness of packing bag.

5), Flatten and align sealing opening, then deliver the bag by aligning the bag

opening with the feed opening, when the bag opening is gripped by the sealing

belts, which makes the bag move forward automatically, at that moment,

please do not push it in or pull it out by force, otherwise irregular sealing or

breakdown will happen.

4, If it is found that there is dirt attached to the sealing belt or the heating block, you

need to stop the sealer and clear it.

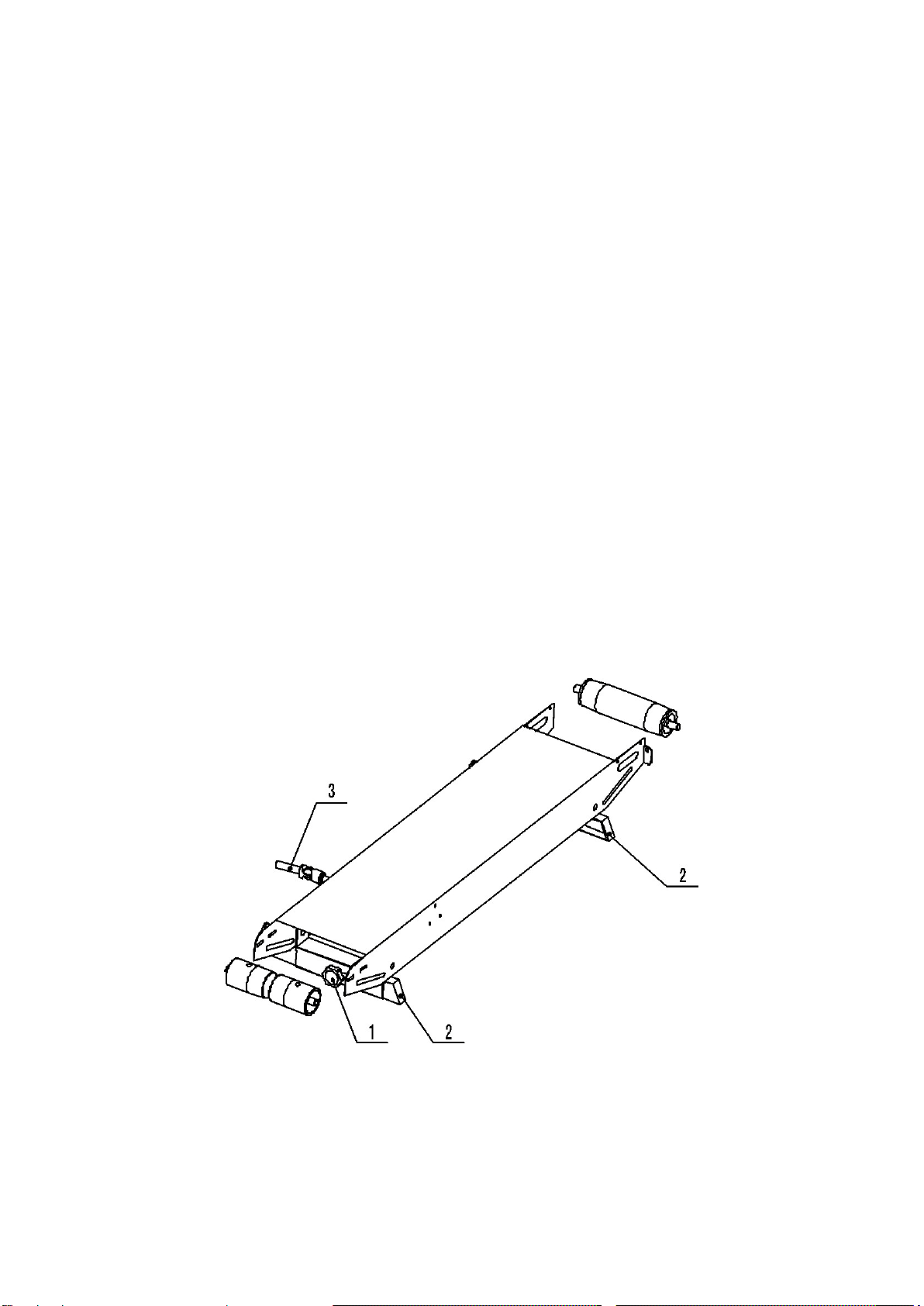

5, Ways of exchanging and adjusting the sealing belt

1),Remove the safety cover, turn stopping flakes on both upper heating block and

upper cooling block by 30° to lift these two blocks after the heating block being

cooled, then loosen the springs both on embossing wheel and pressing wheel,

then remove the guiding belt, so as to make it ready for removing sealing belts.

(see diagram 3)

2), Move the driven wheel seat (adjusting block) toward heating block, and remove

the sealing belt then.

3), Replace with a new sealing belt and install the guiding belt back.

4), Put the driven wheel, heating and cooling blocks, and pressing wheel etc to the

original position.

5), Connect the power supply and test the machine, if irregular sealing appears on

the belt, you can make adjustment through adjusting screws on driven wheel

seat (adjusting block).

6), Install the safety cover. Once the temperature reaches the set temperature, the