3

TABLE OF CONTESTS

1.Foreword...............................................................................................................................5

1.1 Safety.................................................................................................................................................5

1.2 Notation and conventions ..................................................................................................................5

1.3 Safety precautions..............................................................................................................................6

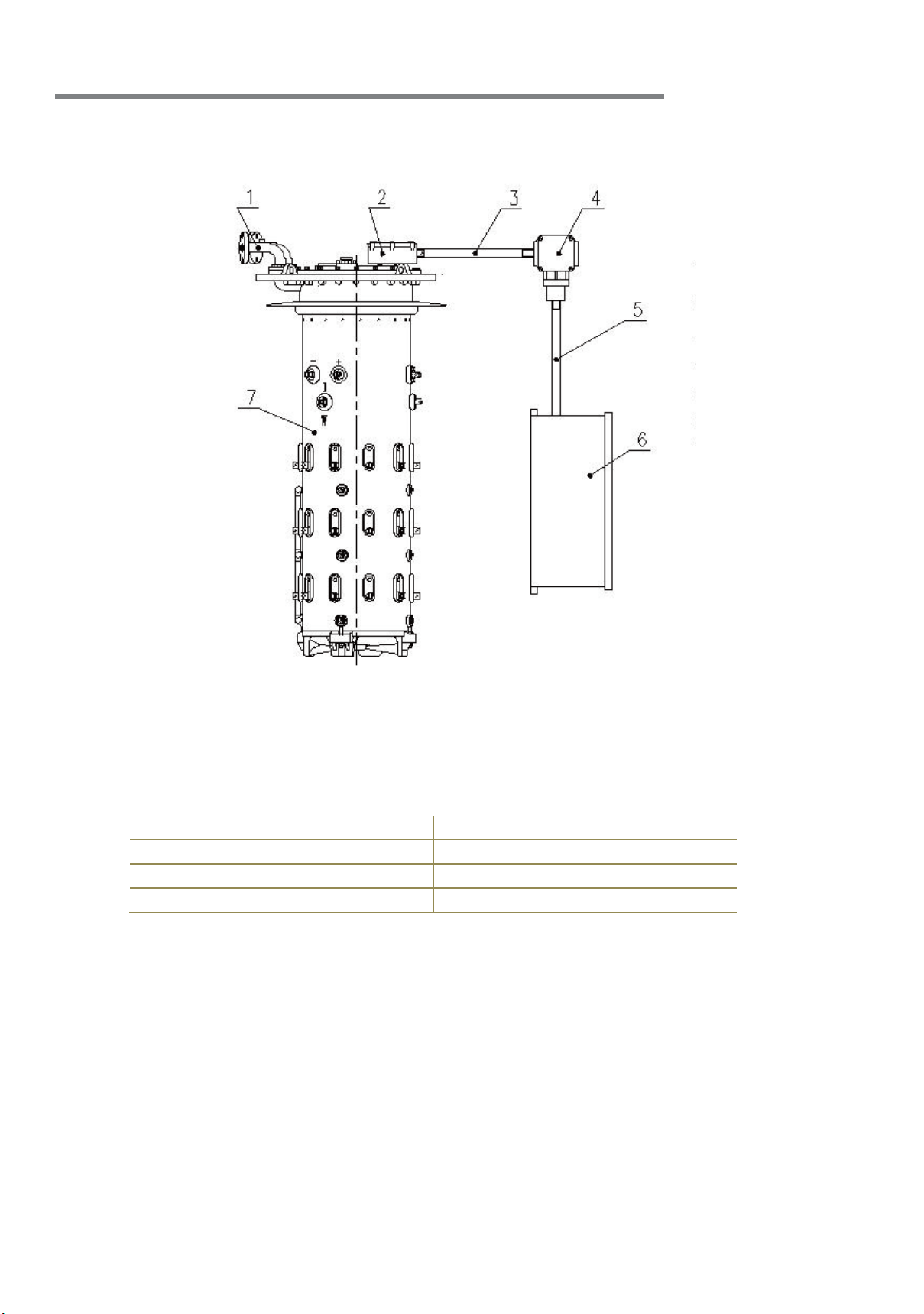

2. General ................................................................................................................................7

3. Technical data......................................................................................................................9

3.1 Table of technical data.......................................................................................................................9

3.2 Operation conditions........................................................................................................................10

4. Type designation................................................................................................................11

4.1 Type designation ..............................................................................................................................11

4.2 Internal insulation level....................................................................................................................12

4.3 Tap selector wiring diagram ............................................................................................................13

5. Packing, transportation & storage......................................................................................14

5.1 Supplied components .......................................................................................................................14

5.2 Transportation & acceptance ...........................................................................................................14

5.3 Storage

.............................................................................................................................................16

6. Mounting of tap-changer on the transformer......................................................................17

6.1 Transformer mounting flange for tap-changer installation...............................................................17

6.2 Mounting of tap-changer on standard type transformer ...................................................................18

6.3 Mounting of tap-changer on bell-type transformer...........................................................................20

6.4 Connection between tap of voltage regulating winding and terminal of tap-changer......................27

7. Transformer ratio test and transformer DC resistance measurement..................................28

7.1 Transformer ratio test........................................................................................................................28

7.2 Transformer DC resistance measurement.........................................................................................29

8. Drying process and oil filling.............................................................................................30

8.1 Drying process.................................................................................................................................30

8.2 Oil filling...........................................................................................................................................34

9. Installation of tap-changer protection device and transmission device components...........35

9.1 Installation of gas relay.....................................................................................................................35

9.2 Use of pressure relief device.............................................................................................................35

9.3 Installation of motor drive unit.........................................................................................................35

9.4 Installation of bevel gear box............................................................................................................35

9.5 Installation of horizontal and vertical drive shafts............................................................................37

9.6 Installation of driving shaft shield cover ..........................................................................................39

9.7 Installation of tap-changer group......................................................................................................41

9.8 Tap position calibration of tap-changer transmission system...........................................................43

10. Tap-changer Factory test and test preparation..................................................................44

10.1Test preparation ...............................................................................................................................44

10.2Test in transformer factory ..............................................................................................................46

11. Transformer transportation and put into operation on site................................................48

11.1 Remove the MDU for transportation..............................................................................................48

11.2 Oil filling and transportation without oil conservator.....................................................................48

11.3 Transportation without oil...............................................................................................................48

11.4 Putting transformer into operation on site ......................................................................................49

12. Tap-changer operation monitoring and maintenance .......................................................50

13. Maintenance.....................................................................................................................51

13.1 Inspection........................................................................................................................................52

13.2 Maintenance interval.......................................................................................................................52

13.3 Recommendation of oil filter installation.......................................................................................53