III

Table of Contents

Foreword..................................................................................................................................................................I

Important Safeguards and Warnings..............................................................................................................II

Table of Contents................................................................................................................................................III

1Product Overview.............................................................................................................................................. 1

1.1 Product Introduction ................................................................................................................................. 1

1.2 Product Feature......................................................................................................................................... 1

1.3 Packing List................................................................................................................................................ 1

1.4 Product Structure...................................................................................................................................... 2

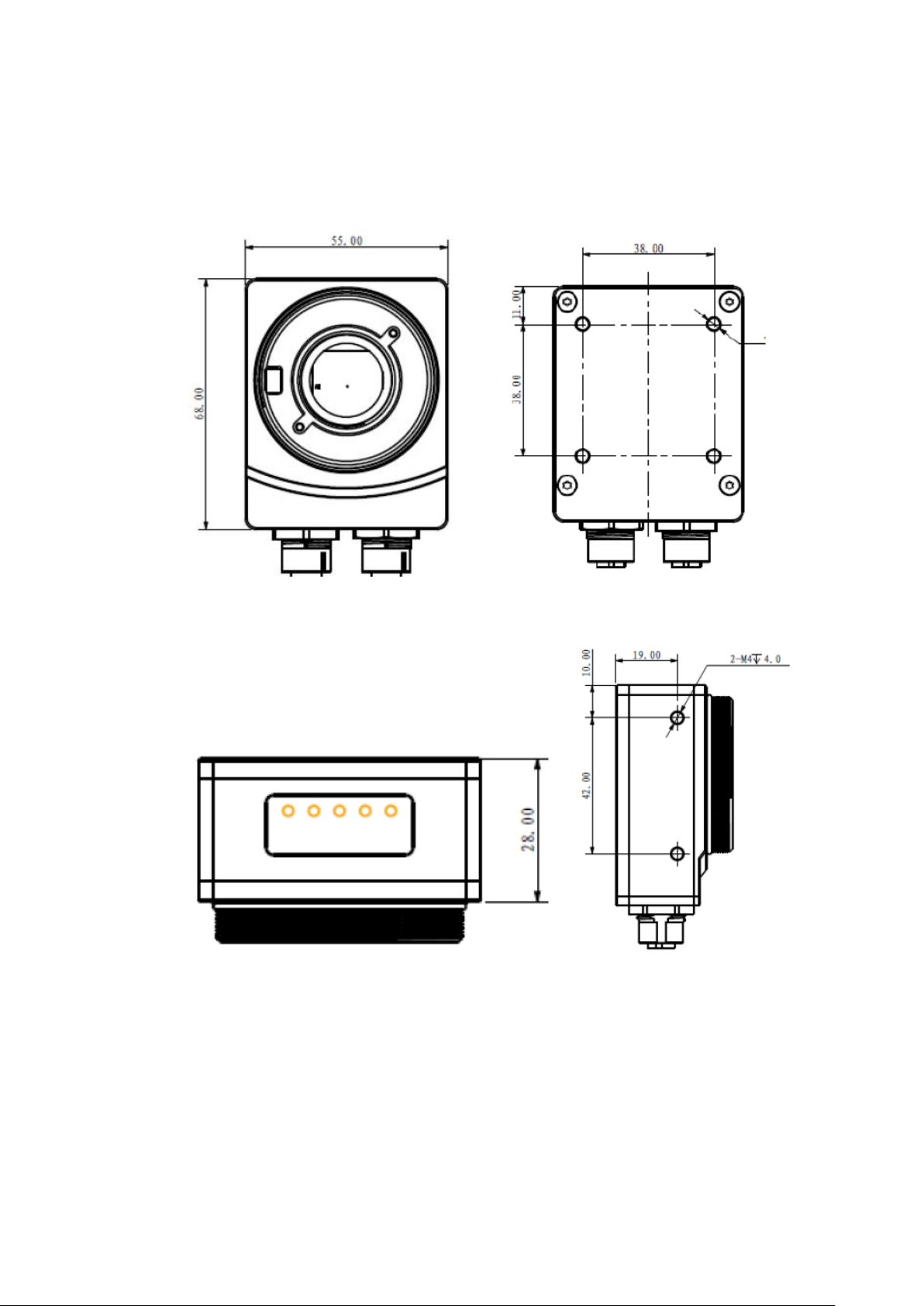

1.4.1 Product Dimension........................................................................................................................ 2

1.4.2 Interface Description..................................................................................................................... 2

8-pin Network Interface.......................................................................................................................... 3

12-pin Power and I/O Interface............................................................................................................. 3

1.5 Electric Specification................................................................................................................................. 4

1.5.1 Electric Specification of Power and Network Interface............................................................ 4

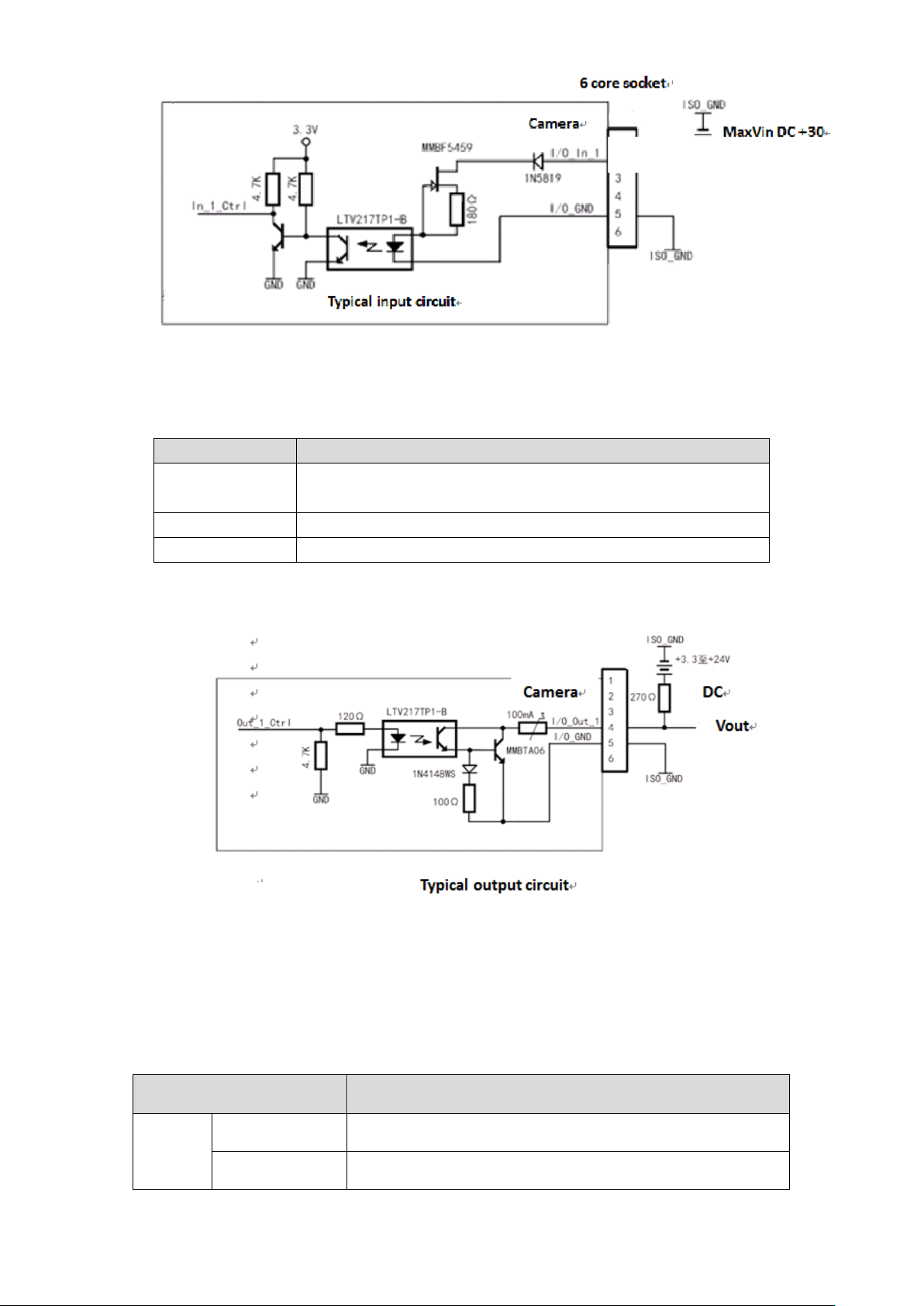

1.5.2 Electric Specification of IO Interface.......................................................................................... 4

1.6 Indicator Light Description....................................................................................................................... 5

1.7 Environmental Requirement.................................................................................................................... 6

2Typical Networking......................................................................................................................................... 7

3Product Installation........................................................................................................................................... 8

3.1 Hardware Installation................................................................................................................................ 8

3.1.1 Camera Installation....................................................................................................................... 8

3.2 App Installation.......................................................................................................................................... 9

4Setting of Smart Camera................................................................................................................................ 12

4.1 Config Wizard.......................................................................................................................................... 12

4.2 Disconnect and Connect Camera ........................................................................................................ 14

4.3 Image Setting .......................................................................................................................................... 16

4.4 Vision Setting........................................................................................................................................... 19

4.5 Communication Setting.......................................................................................................................... 21

4.6 IO Control Setting ................................................................................................................................... 24

4.7 Config Management............................................................................................................................... 26

4.8 Vision Mode Operation........................................................................................................................... 26

4.8.1 Vision Mode................................................................................................................................. 26

4.8.2 Image Display.............................................................................................................................. 27

4.8.3 Result............................................................................................................................................ 27

4.9 Save Images............................................................................................................................................ 28

5Main Functions................................................................................................................................................. 29

5.1 Device Info............................................................................................................................................... 29

5.2 Image Setting .......................................................................................................................................... 30

5.2.1 Exposure...................................................................................................................................... 30

5.2.2 Focus............................................................................................................................................ 31