Huawei FusionServer Pro G5500 Instructions for use

Other Huawei Server manuals

Huawei

Huawei FusionServer Pro 1288H V5 User manual

Huawei

Huawei 2288H V5 User manual

Huawei

Huawei FusionServer Pro 2488H V6 Quick reference guide

Huawei

Huawei FusionModule2000 V500R003C10 Operating manual

Huawei

Huawei V100R002C01 User manual

Huawei

Huawei FusionModule2000 V500R003C10 User manual

Huawei

Huawei E9000 User manual

Huawei

Huawei FusionServer Pro 2488 V5 Quick reference guide

Huawei

Huawei FusionModule1000A20 User manual

Huawei

Huawei FusionModule500 User manual

Huawei

Huawei ViewPoint 9000 Series User manual

Huawei

Huawei SVN2000 Series User manual

Huawei

Huawei Tecal RH2285 User manual

Huawei

Huawei G5500 User manual

Huawei

Huawei FusionModule5000 Operating manual

Huawei

Huawei NetCol5000-A-035 User manual

Huawei

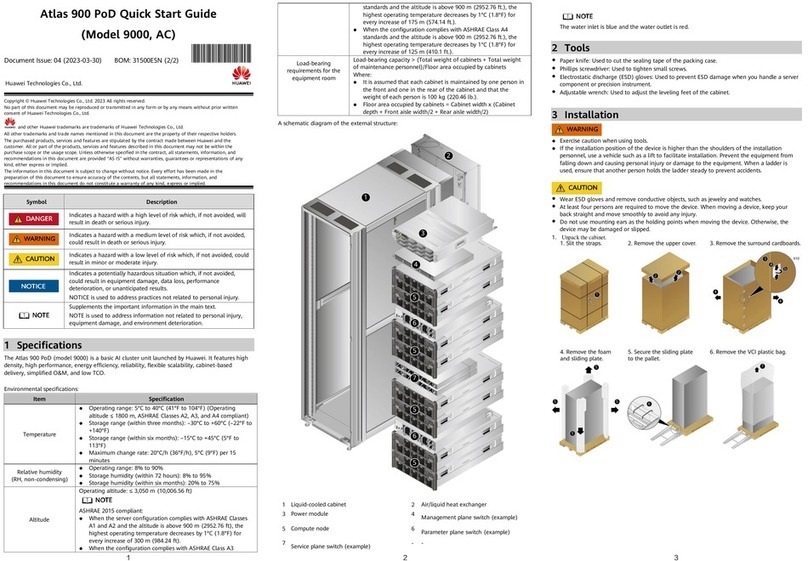

Huawei TaiShan 200 Quick reference guide

Huawei

Huawei FusionServer Pro CH242 V5 Quick reference guide

Huawei

Huawei iManager NetEco 6000 User manual

Huawei

Huawei TaiShan 200 Series User manual