6. List of Manufacturer Parameters

Ⅵ. List of Manufacturer Parameters

Parameters used to store relevant data set by air compressor manufacturers. To view manufacturer

parameters, the manufacturer password must be verified. In the first-level menu, press or key to

move the black scroll bar to the "Manufacturer Parameters" menu, and then press key to enter the

menu below:

After entering the correct manufacturer password and pressing key, user can enter the manufacturer

parameter interface as shown below:

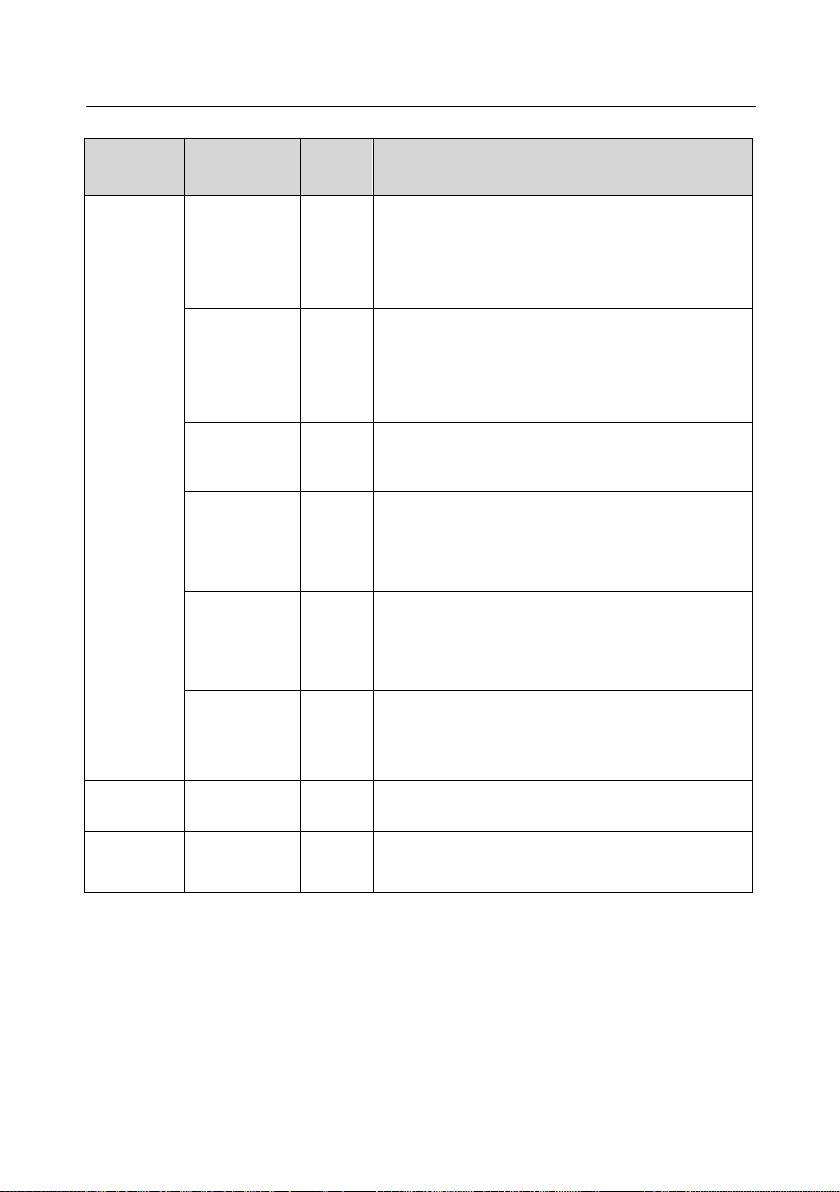

System

Parameters

Air End 1

Current

allowable

motor

overload

After delay start of Air End 1, the machine will

present a delay shutdown according to overload

characteristics when the motor current is more

than 1.2 times of the set value.

Air End 2

Current

allowable

motor

overload

After delay start of Air End 2, the machine will

present a delay shutdown according to overload

characteristics when the motor current is more

than 1.2 times of the set value.

1

105℃When Air End 1 temperature is higher than this

set temperature, a warning will be given.

1

110℃When Air End 1 temperature is higher than this

set temperature, fault shutdown will be reported.

1.00MPa

When the air supply pressure is higher than the

set pressure, fault shutdown will be reported.

Unload

0.80MPa

Maximum allowable unloading pressure limited

by manufacture on user settings. Unloading

pressure is less than or equal to this set value.

000000 hrs Modify the total running time of Air End 1.

System Parameters

Maintenance Parameter Reset

Maximum Operating Time Preset

Enter Password

****