CATALOGUE

Summary............................................................................................................................................................ 1

1. Components........................................................................................................................................... 1

2. Connection............................................................................................................................................. 1

3. Features..................................................................................................................................................2

4. Usage......................................................................................................................................................2

5. Symbol Instruction................................................................................................................................. 2

6. Working Environment............................................................................................................................ 3

Technical Parameter...........................................................................................................................................3

1. Power source SLG-200HF、SLG-300HF、SLG-400HF........................................................................... 3

2. Arc initiator QFK-E1................................................................................................................................6

3. Requirements of gas supply...................................................................................................................7

4. Requirement of torch coolant................................................................................................................7

Panel Function....................................................................................................................................................8

1. Power source front panel.......................................................................................................................8

2.Arc initiator panel..................................................................................................................................11

3. Secondary menu.................................................................................................................................. 12

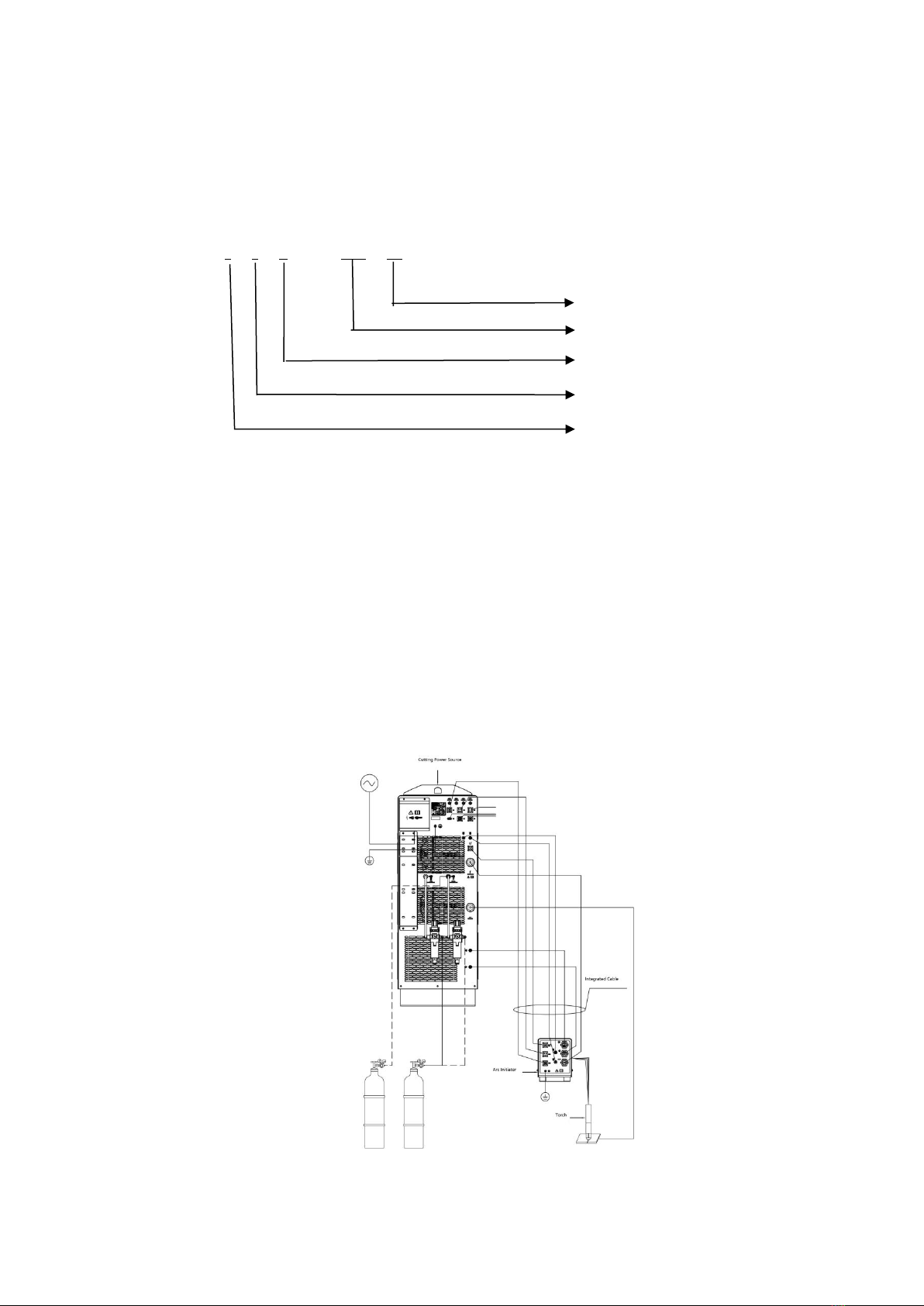

Installation........................................................................................................................................................13

1. Acceptance inspection......................................................................................................................... 13

2. Product defect......................................................................................................................................13

3. Installation requirement...................................................................................................................... 13

4. Noise.....................................................................................................................................................13

5. Ground connection and shield installation..........................................................................................13

6. Installation drawing..............................................................................................................................14

7. Installation of plasma cutting power source(Part A)..................................................................... 16

8. Installation of arc initiator(5-2 Part B)........................................................................................... 17

9. Torch installation(5-2 Part C)..........................................................................................................18

10. Cable and hose installation(5-2 ○

1~○

18)...................................................................................... 18

11. Filling coolant liquid........................................................................................................................... 22

12. Setting of gas supply.......................................................................................................................... 22

13. Optimize the cutting quality.............................................................................................................. 23

14. Inspection before operate................................................................................................................. 25