CATALOGUE

Summary.....................................................................................................................................6

Model description................................................................................................................6

Features................................................................................................................................6

Usage...................................................................................................................................6

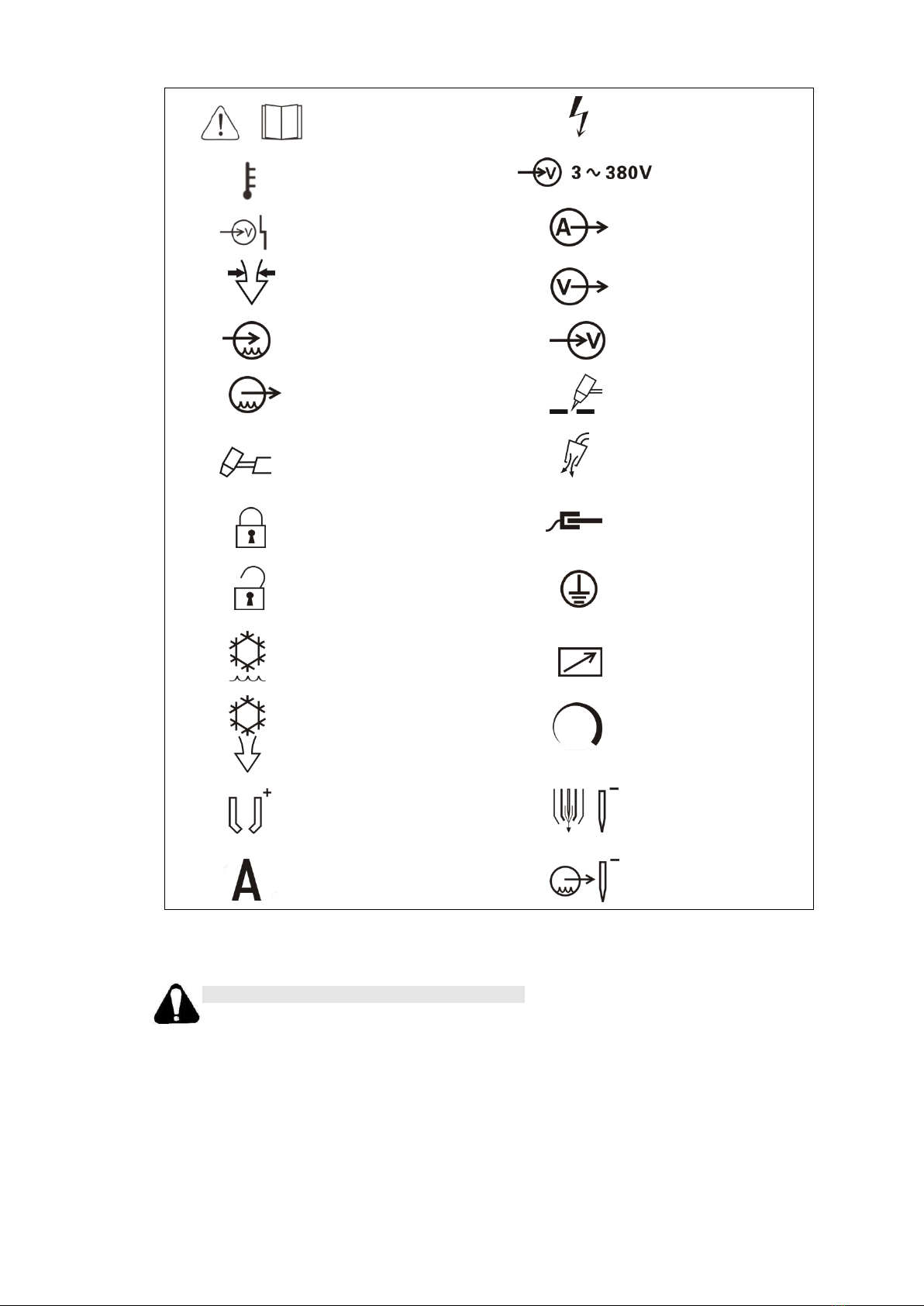

Symbol instructions.............................................................................................................6

Safety and attention ....................................................................................................................7

Working Environment Requirements .........................................................................................8

Environmental condition .....................................................................................................8

Power supply condition.......................................................................................................8

Technical parameters..................................................................................................................8

Main technical parameters...................................................................................................8

Plasma gas condition...........................................................................................................9

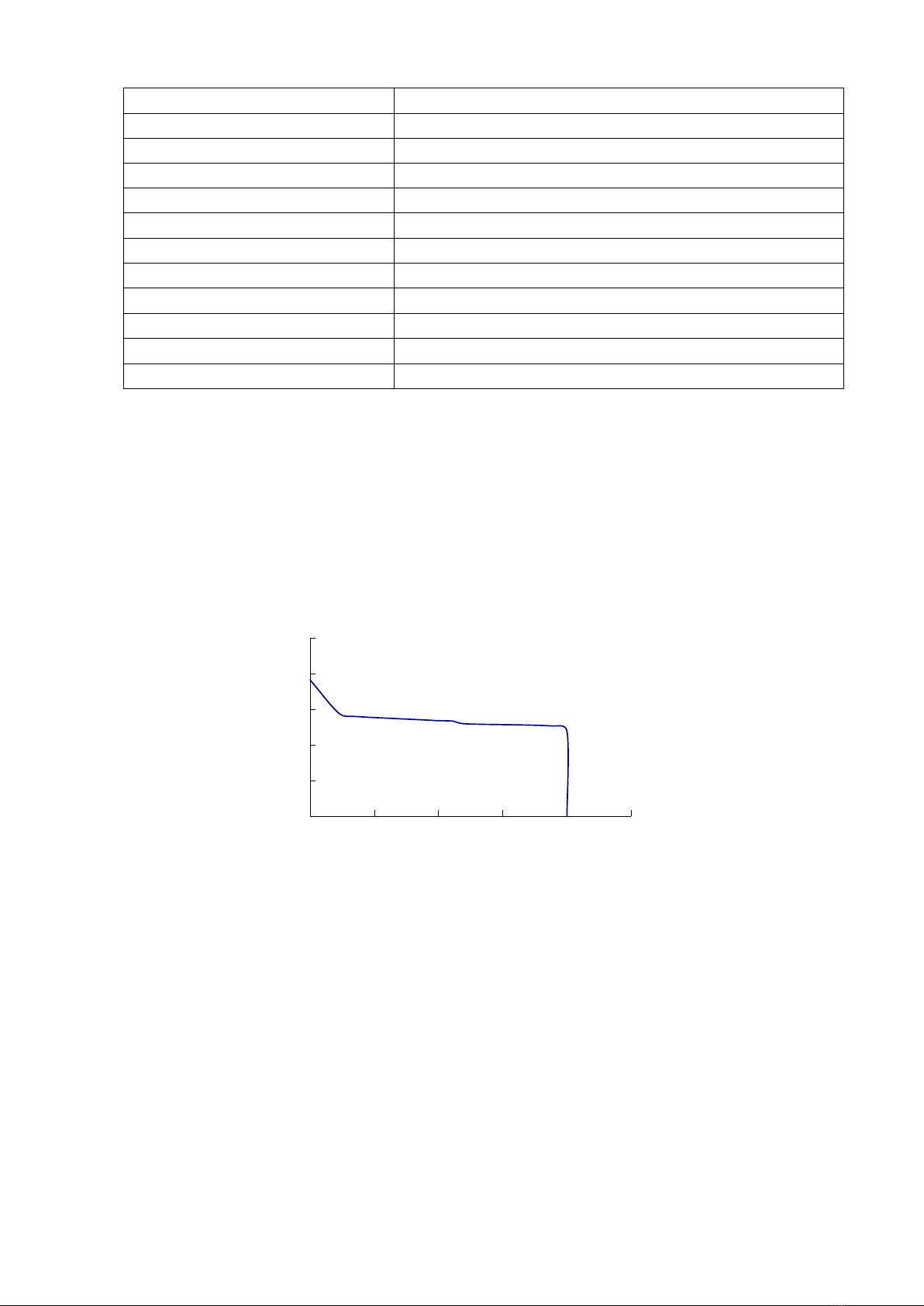

External characteristic curve ...............................................................................................9

System instruction ......................................................................................................................9

Working principles ..............................................................................................................9

Machine working theory....................................................................................................10

Installation and operation .........................................................................................................10

Moving and lifting.............................................................................................................10

Open the packing and check..............................................................................................10

The fix and installation of the plasma power source.........................................................10

The connection of three phase input cable ........................................................................11

Panel and its functions.......................................................................................................13

Protection function introduction........................................................................................14

Operation...........................................................................................................................15

Gouging operation.............................................................................................................16

Cutting operation...............................................................................................................16

Gouging technology instruction ...............................................................................................17

Cutting technology instruction .................................................................................................19

The related main technical parameters..............................................................................19

Eliminate the cutting burr..................................................................................................20

Repair and maintenance............................................................................................................21

Trouble shooting.......................................................................................................................21

Trouble shooting................................................................................................................21

Some main components sheet............................................................................................23

Packing list ...............................................................................................................................23

Attached diagram:main circuit diagram ................................................................................24