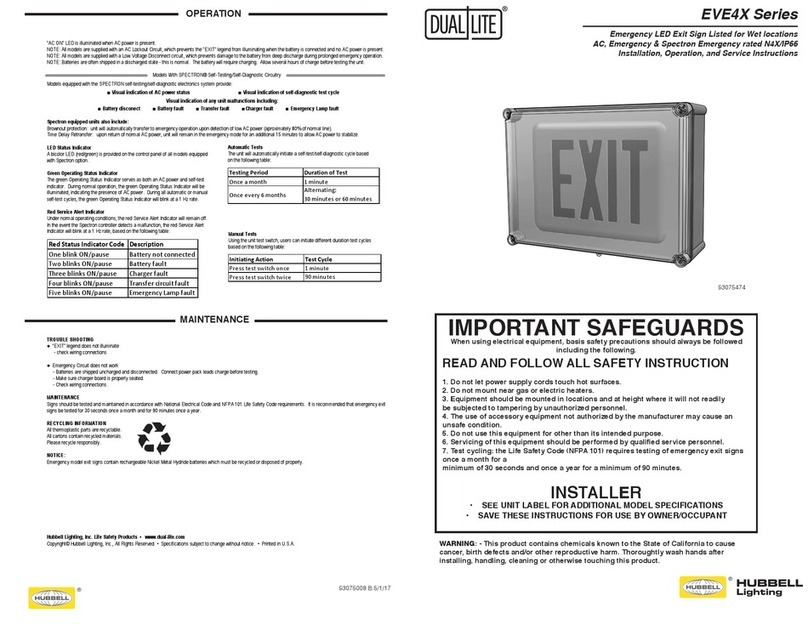

“AC ON” LED is illuminated when AC power is present.

NOTE: All models are supplied with an AC Lockout circuit, which prevents the emergency lights from illuminating

when the battery is connected and no AC power is present.

NOTE: All models are supplied with a Low Voltage Disconnect circuit, which prevents damageto the battery from

deep discharge during prolonged emergency operation.

NOTE: Batteries are often shipped in a discharged state – this is normal. The battery will require charging. Allow

24 hours of charging before testing the unit.

Models with SPECTRON®Self-Testing/Self-Diagnostic Circuitry

Models equipped with the Spectron® self-testing/self-diagnostic electronics system provide:

Visual indication of AC power status Visual indication of self-diagnostic test status and results

-- Visual indication of any unit malfunctions include –

Battery Disconnected Battery Fault Charger Fault LED Driver Fault Lamp Fault

Spectron equipped units also include:

Brownout protection: unit will automatically transfer to emergency operation upon detection of low AC power (approximately 80% of

nominal line).

Time Delay Retransfer: upon return of normal AC power, unit will remain in emergency mode for an additional 15 minutes to allow AC

power to stabilize.

LED Status Indicator

A bicolor LED (green/red) is provided on the control panel

of all models equipped with the Spectron® option.

Green Operating Status LED:

The green Operating Status LED serves as both an AC

power and self-test indicator. During normal operation,

the green Operating Status LED will be illuminated,

indicating the presence of AC power. During all auto-

matic or manual self-test cycles, the green Operating

Status LED will blink twice every second.

Red Service Alert LED:

Under normal operating conditions, the red Service Alert

LED indicator will remain off. If the Spectron® controller

detects a malfunction, the red Service Alert LED will blink

in the pattern listed in the following table:

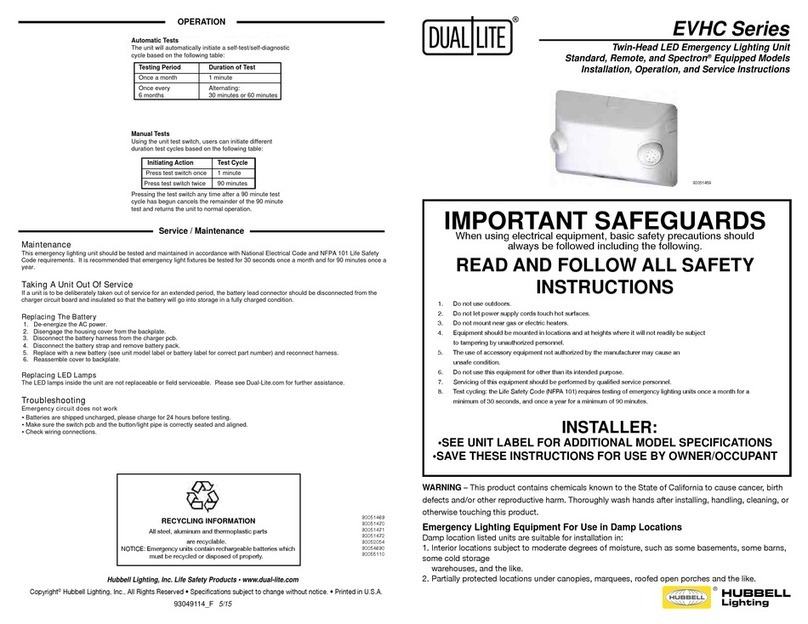

Automatic Tests

The unit will automatically initiate a self-test/self-diagnostic

cycle based on the following table:

Testing Period Duration of Test

Once a month 1 minute

Once every 6

months

Alternating:

30 minutes or 60 minutes

Using the unit test switch, users can initiate different

duration test cycles based on the following table:

Initiating Action Test Cycle

Press test switch once 1 minute

Press test switch twice 90 minutes

Pressing the test switch any time after a 90 min. test

cycle has begun cancels the remainder of the 90 min. test

and returns the unit to normal operation.

Red Status LED Code Description

One blink ON/pause Battery disconnected

Two blinks ON/pause Battery fault

Three blinks ON/pause Charger fault

Four blinks ON/pause LED Driver fault

Five blinks ON/pause Lamp fault

Red/Green alternating Load Learn in Process

OPERATION OPERATION

“AC ON” LED is illuminated when AC power is present.

NOTE: All models are supplied with an AC Lockout circuit, which prevents the emergency lights from illuminating

when the battery is connected and no AC power is present.

NOTE: All models are supplied with a Low Voltage Disconnect circuit, which prevents damageto the battery from

deep discharge during prolonged emergency operation.

NOTE: Batteries are often shipped in a discharged state – this is normal. The battery will require charging. Allow

24 hours of charging before testing the unit.

Models with SPECTRON®Self-Testing/Self-Diagnostic Circuitry

Models equipped with the Spectron® self-testing/self-diagnostic electronics system provide:

Visual indication of AC power status Visual indication of self-diagnostic test status and results

-- Visual indication of any unit malfunctions include –

Battery Disconnected Battery Fault Charger Fault LED Driver Fault Lamp Fault

Spectron equipped units also include:

Brownout protection: unit will automatically transfer to emergency operation upon detection of low AC power (approximately 80% of

nominal line).

Time Delay Retransfer: upon return of normal AC power, unit will remain in emergency mode for an additional 15 minutes to allow AC

power to stabilize.

LED Status Indicator

A bicolor LED (green/red) is provided on the control panel

of all models equipped with the Spectron® option.

Green Operating Status LED:

The green Operating Status LED serves as both an AC

power and self-test indicator. During normal operation,

the green Operating Status LED will be illuminated,

indicating the presence of AC power. During all auto-

matic or manual self-test cycles, the green Operating

Status LED will blink twice every second.

Red Service Alert LED:

Under normal operating conditions, the red Service Alert

LED indicator will remain off. If the Spectron® controller

detects a malfunction, the red Service Alert LED will blink

in the pattern listed in the following table:

Automatic Tests

The unit will automatically initiate a self-test/self-diagnostic

cycle based on the following table:

Testing Period Duration of Test

Once a month 1 minute

Once every 6

months

Alternating:

30 minutes or 60 minutes

Using the unit test switch, users can initiate different

duration test cycles based on the following table:

Initiating Action Test Cycle

Press test switch once 1 minute

Press test switch twice 90 minutes

Pressing the test switch any time after a 90 min. test

cycle has begun cancels the remainder of the 90 min. test

and returns the unit to normal operation.

Red Status LED Code Description

One blink ON/pause Battery disconnected

Two blinks ON/pause Battery fault

Three blinks ON/pause Charger fault

Four blinks ON/pause LED Driver fault

Five blinks ON/pause Lamp fault

Red/Green alternating Load Learn in Process

Note: After clearing a 5 blink lamp fault by initiating a load learn

test, a 60 second manual test must be initiated.

Note: After clearing a 5 blink lamp fault by initiating a load

learn test, a 60 second manual test must be initiated.