Manual M-800 Rev. 6/09Manual M-800 Rev. 6/09 Page 3 of 16

OPERATING PROCEDURE

Filling the Reservoir

NOTE: The pump has been shipped without oil in the reservoir. A high-

quality, approved hydraulic oil has been shipped with the pump in a

separate container. If additional oil is required, use an approved hydraulic

oil only.

1. Cleantheareaaroundthellercaptoremovealldustandgrit.Anydirtordust

intheoilcandamagethepolishedsurfacesandprecision-tcomponentsof

thispump.

2. Retractallcyclinder(s)totheirreturnposition.

3. Removethellercapandinsertacleanfunnelwithalter.Fillthereservoir

withahigh-quality,approvedhydraulicoiltowithin1”ofthecoverplate.

Replacethellercap.

4. Cyclethepump(withthecylinder(s)attached)severaltimes.Retractthe

cylinder(s)andchecktheoillevelinthepumpreservoir.

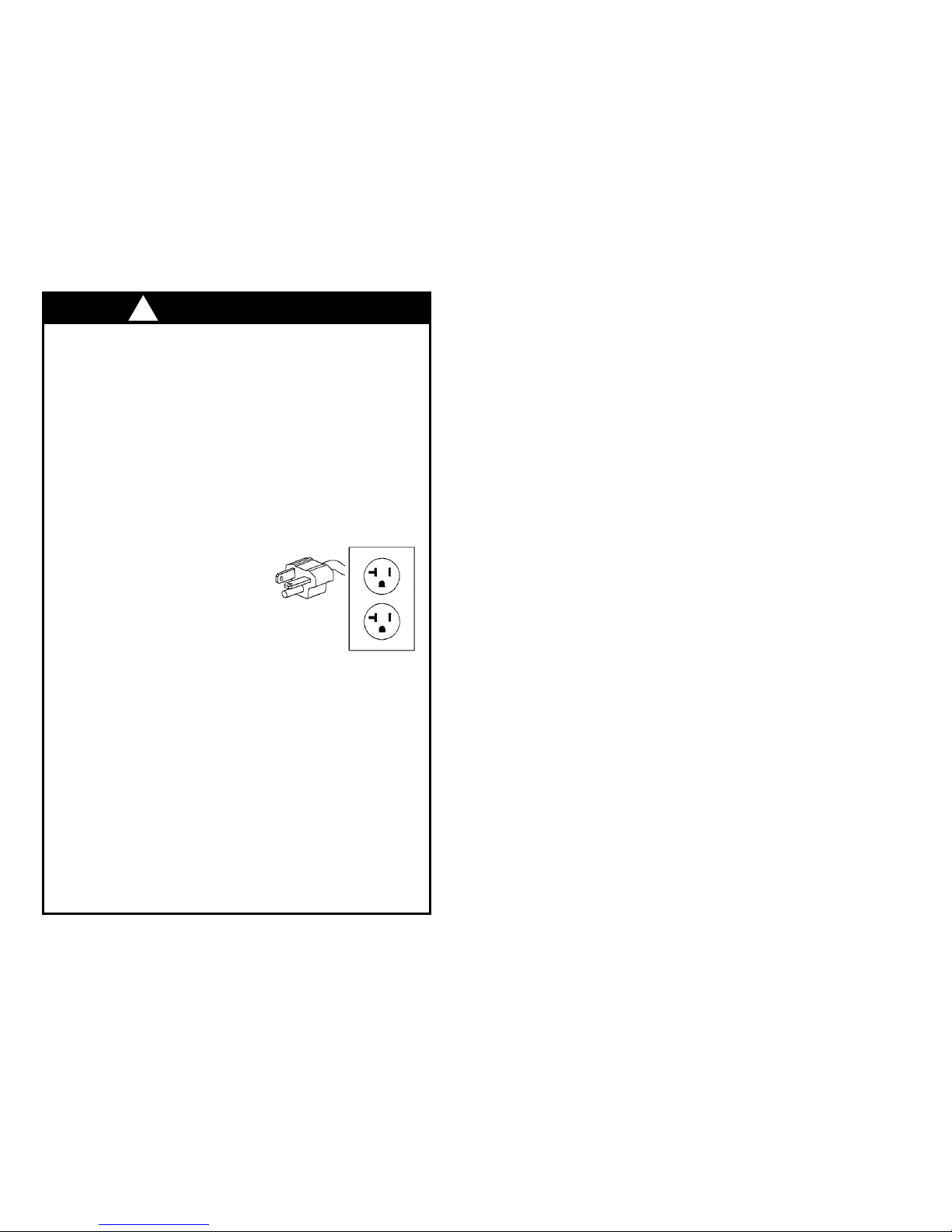

Electrical Hook-up and Operation

To help avoid personal injury:

• Allelectricalworkmustbedonebyaqualiedelectrician.

• Disconnectthepowersupplybeforeremovingmotorcasingcoveror

performingrepairsormaintenance.

• Allvoltagesmustbewiredforcounterclockwiserotationwhenviewed

fromtheleadendofthemotor.

• Changingthevoltageonthisunitisaninvolved,andifproperly

performed,hazardousprocedure.Consultthemanufacturerforspecic

informationbeforeattemptinganyrewiring.

WARNING

!

1. Theelectricmotorisasinglephase,60cycleandcanbewiredat115or230

volts.

Page 14 of 16

Material Safety Data Sheet

Section 1. Chemical Product and Company

Identifcation.

ProductName:AW Hydraulic Oil ISO 46

Code/PartNumber:9636,9637,9638,9616,

11360,9647

Manufacturer: SPXFluidPower

588511thStreet

Rockford,IL61109,USA

Phone:815-874-5556

CHEMTREC 24 Hr. Emergency Number:

800-424-9300

MaterialUse: Theproductdesignedforusein

heavydutyHydraulicuid

applications.

ValidatedonJanuary,2007

Section 2. Composition and Information on

Ingredients.

Name:Hydrotreatedorseverelyrenedbaseoil

andproprietaryadditivesCAS#:Mixture

%(V/V):100

ExposureLimits:

TLV-TWA(8hr):5mg/cubicm(oilmist)

STLE:10mg/cubicm(oilmist)

ManufacturerRecommendation:Notapplicable

OtherExposureLimits:Consultlocal,state,

provincialorterritorialauthoritiesforacceptable

exposurelimits.

Section 3. Hazardous Identification.

Potentialhealtheffects:Notirritatingtoslightirrita-

tiontoskinandeyeswithnopermanentdamage.

Relativelynon-toxicviaingestion.Thisproducthas

alowvaporpressureandisnotexpectedtopres-

entaninhalationexposureatambientconditions.

Athightemperaturesormechanicalactionsmay

producevaporsormists.Inhalationmaycauseir-

ritationofthebreathingpassages.Seesection11.

Section 4. First Aid Measures

Eye contact:Immediatelyusheyeswithrunning

waterforatleast15minutes,keepingeyelids

open.Seekmedicalattention.

Skin Contact:Removecontaminatedclothing–

launderbeforereuse.Washcontaminatedskin

withrunningwaterandnon-abrasivesoap.Get

medicalattentionifirritationdevelopsorifproduct

isinjectedunderpressureintoorundertheskin.

Inhalation:Removetofreshair.Getmedicalat-

tentionifbreathingdifcultypersists.Ifvictimisnot

breathing,performarticialrespiration.

Ingestion:DONOTinducevomiting.Seekmedi-

calattention.

Section 5. Fire-Fighting Measures

Flammability:Maybecombustiveathightempera-

ture.

Flashpoint:>=200degC(392degF)(COC)

FlammableLimits:Notavailable

Auto-IgnitionTemperature:Notavailable

FireHazardinPresenceofVariousSubstances:

Lowrehazard.Thismaterialmustbeheated

beforeignitionwilloccur.

ExplosionHazardsinPresenceofVariousSub-

stances:Donotcut,weld,drillorpressurizeempty

container.Containersmayexplodeinheatofre.

ProductsofCombustion:variousoxidesofcarbon,

nitrogen,sulfur,smokeandirritatingvaporsfrom

incompletecombustion.

FireFightingMediaInstructions:NAERG96,Guide

171,Substances(lowtomoderatehazard).Iftank,

railcarortankisinvolvedinre,ISOLATEfor800

meters(0.5mile)inalldirections.Shutofffuelto

reifitispossibletodowithouthazard.ifitisnot

possible,withdrawfromareaandletreburnout

undercontrolledconditions.Withdrawimmediately

incaseofrisingsoundfromventingsafetydevice

oranydiscolorationoftankduetore.Coolcon-

tainingvesselswithwatersprayinordertoprevent

pressurebuild-up,autoignitionorexplosion.

SmallFire:useDRYchemicals,foam,waterspray

orCO2.

LargeFire:usewaterspray,fogorfoam.Forsmall

outdoorres,portablereextinguishersmaybe

used.Forallindoorresandsignicantoutdoor

resself-containedbreathingapparatusisre-

quired.Respiratoryandeyeprotectionarerequired

forreghtingpersonnel.

Section 6. Accidental Release Measures

MaterialReleaseorSpill:NAERG96,Guide171,

Substances(lowtomoderatehazard).ELIMINATE

ALLIGNITIONSOURCES.Avoidcontact.Stop

leakifwithoutrisk.Containspill.Absorbwithinert

absorbents.Placeusedabsorbentinclosedmetal

containersforlaterdisposalorburnabsorbentin

suitablecombustionchamber.DONOTFLUSH

TOSEWERS,STREAMSOROTHERBODIESOF

WATER.Checkwithapplicablejurisdictionforspe-

cicdisposalrequirementsofspilledmaterialsand

emptycontainers.Notifytheappropriateauthorities

immediately.

Section 7. Handling and Storage

Handling:Avoidinhalationandskincontact

especiallywhenhandlingusedoil.Keepawayfrom

sourcesofignition.Donotreuseemptycontain-

erswithoutcommercialreconditioning.Practice

goodpersonalhygiene.Washhandsafterhandling

oilandbeforeeating.Launderworkclothesfre-

quently.Discardsaturatedleathergoods.

Storage:Storeintightlyclosedcontainersincool,

dry,isolated,well-ventilatedarea,andawayfrom

incompatibles.

Material Safety Data Sheet Page 1

AW Hydraulic Oil ISO 46