Page | vi

TableofContents

SAFETY WARNINGS...........................................................................................................iii

1 Introduction ....................................................................................................................... 1

1.1 Overview..................................................................................................................... 1

1.2 Applicability................................................................................................................. 2

2. Cabinet Setup .................................................................................................................. 3

2.1 Inspecting the Equipment ........................................................................................... 3

2.2 Floor Loading.............................................................................................................. 3

2.3 Clearances ................................................................................................................. 3

2.4 Unloading the Cabinet(s)............................................................................................ 4

2.5 Attaching the Cabinet to the UPS............................................................................... 5

3. Electrical Installation......................................................................................................... 6

3.1 Overview..................................................................................................................... 6

3.2 Wiring Preparation...................................................................................................... 6

3.3 Wiring Installation ....................................................................................................... 8

3.4 Control Connections (MBS Arrangement Only).......................................................... 9

3.4.1 Connections Between the Maintenance Bypass Switch and the UPS (MBS

Arrangement Only)........................................................................................................ 9

3.4.2 Terminal Strip Torque Requirements (MBS Arrangement Only).......................... 9

3.4.3 Switch Settings (MBS Arrangement Only).......................................................... 10

4. Backfeed Protection (MBS Arrangement Only).............................................................. 12

4.1 Remote EPO (Emergency Power Off) (MBS Arrangement Only)............................. 12

5. Operation (MBS Arrangement Only) .............................................................................. 14

5.1 To transfer from normal mode on the UPS to maintenance bypass—...................... 15

5.2 To transfer from MBS to normal mode—.................................................................. 15

5.3 Normal start-up with load unpowered—.................................................................... 15

5.4 Need to get power to the load, but the condition of the UPS is uncertain— ............. 15

5.5 Need to operate the UPS as part of maintenance, but wish to maintain power to.... 16

5.6 Potential Problems:................................................................................................... 16

5.7 REPO (MBS Arrangement Only) .............................................................................. 17

6. Maintenance................................................................................................................... 19

7. Technical Specifications................................................................................................. 20

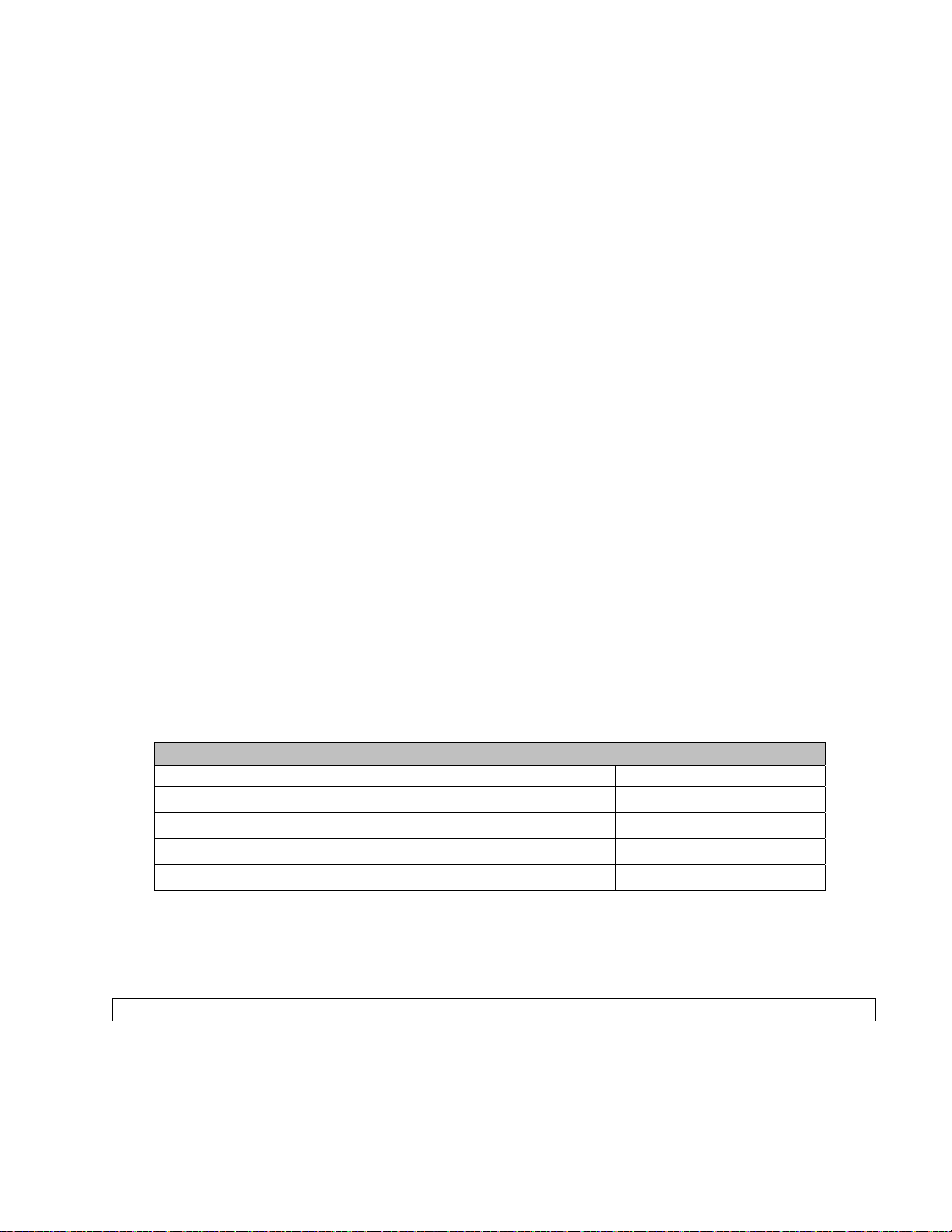

Table 1 - Symbols ................................................................................................................iii

Table 2 - Model Floor Loadings............................................................................................ 3

Table 3 - Maintenance Bypass Switch States.................................................................... 17

Table 4 - Maintenance Bypass Switch State Change Procedures ..................................... 18

Table 5 - Technical Specifications...................................................................................... 20

Table 6 - Wire Size Requirements and Maximum Current Ratings.................................... 21

Table 7 - Terminal Tightening Torques .............................................................................. 22

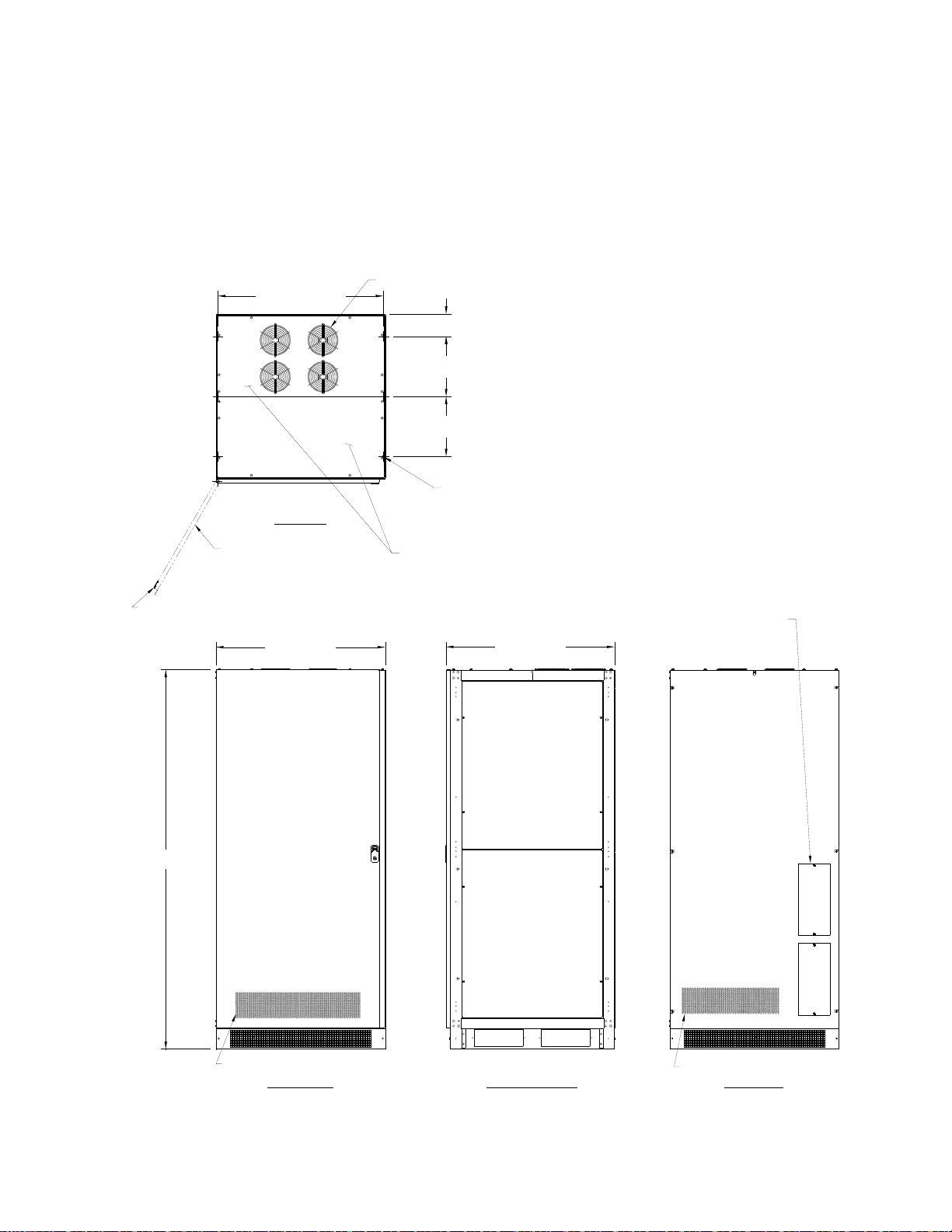

Figure 1 – Outline Drawing................................................................................................... 1

Figure 2 - Pallet Mounting Hardware.................................................................................... 4

Figure 3 - Cabinet to Cabinet Mounting Hole Locations....................................................... 5

Figure 4 - Inside Front View of Transformer Cabinet............................................................ 7

Figure 5 - Cabinet Top Conduit Locations............................................................................ 7

Figure 6 - Options Control Board Assembly....................................................................... 10

Figure 7 - Customer Low Voltage Connection Terminal Block........................................... 11

Figure 8 - Circuit Breaker Sequence Label ........................................................................ 17