OPERATION MANUAL

Piccolo V1.1.0en/31.01.22//1.0.0

3.2 Information on the thermal fluids ................................................................ 26

3.3 To be noted when planning the test ............................................................. 27

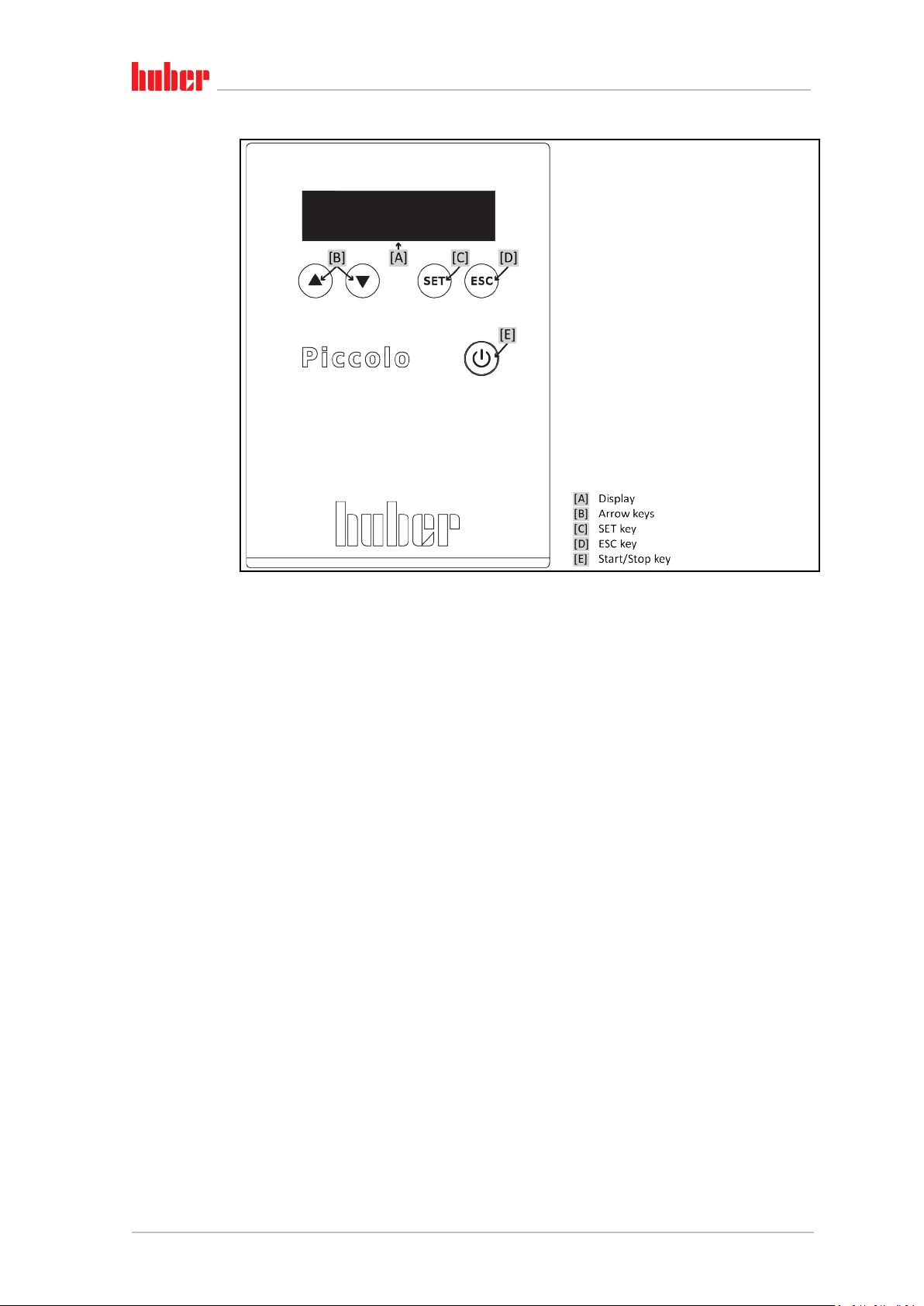

3.4 Display and control instruments................................................................... 28

3.4.1 Display.............................................................................................................28

3.4.2 Control instruments........................................................................................29

3.4.2.1 Arrow keys..................................................................................................29

3.4.2.2 SET key........................................................................................................29

3.4.2.3 ESC key .......................................................................................................30

3.4.2.4 Start/Stop key.............................................................................................30

3.4.3 Adjusting settings............................................................................................30

3.5 Menu function ............................................................................................. 31

3.6 Functional examples .................................................................................... 32

3.6.1 Selecting a language .......................................................................................32

3.6.2 Setting the setpoint ........................................................................................32

3.6.3 Changing the Auto-Start function ...................................................................32

4Setup mode 33

4.1 Setup mode ................................................................................................. 33

4.1.1 Turning on the temperature control unit .......................................................33

4.1.2 Turning off the temperature control unit.......................................................33

4.2 Filling, venting and draining ......................................................................... 33

4.2.1 Cooling circuit .................................................................................................34

4.2.1.1 Filling the cooling circuit.............................................................................34

4.2.1.2 Draining the cooling circuit ........................................................................34

4.2.2 Externally closed application ..........................................................................35

4.2.2.1 Filling and venting externally closed application........................................35

4.2.2.2 Draining externally closed applications......................................................36

5Normal operation 37

5.1 Automatic operation.................................................................................... 37

5.1.1 Temperature control.......................................................................................37

5.1.1.1 Starting the temperature control process..................................................37

5.1.1.2 Ending the temperature control process ...................................................37

6Interfaces and data communication 38

6.1 Interfaces on the temperature control unit................................................... 38

6.1.1 Interfaces at the back .....................................................................................38

6.1.1.1 USB-2.0 interface........................................................................................38

6.1.1.2 RS232 jack...................................................................................................38

6.2 Data communication.................................................................................... 39

6.2.1 LAI commands.................................................................................................39

6.2.1.1 Command “V” (Verify)................................................................................40

6.2.1.2 Command “L” (Limit) ..................................................................................40

6.2.1.3 Command “G” (General) ............................................................................41

6.2.2 PP commands..................................................................................................42

7Service/maintenance 44

7.1 Displays in the event of faults....................................................................... 44

7.2 Electrical fuse............................................................................................... 45

7.3 Maintenance................................................................................................ 45

7.3.1 Function check and visual inspection .............................................................45

7.3.2 Replacing temperature control hoses.............................................................46

7.3.3 Testing overheat protection for functionality.................................................47