BS

BSBS

BS-

--

-300R

300R300R

300R

Universal surface grinder

Strana 1

Read the operator’s manual carefully and understand the contents before you use this equipment.

Always use the machine in accordance with all the instructions contained in this manual, in order to

ensure safe and efficient operation as well as longevity of the machine.

The manufacturer can not be held responsible for any damages or injury arising from the use of the

machine not in accordance with the instructions contained in this manual.

CONTENTS

1. SAFETY INSTRUCTION .......................................................................2

1.1.

General safety instructions..................................................................................................2

1.1.1.

Qualification requirements....................................................................................2

1.1.2.

Duties of the entrepreneur:....................................................................................2

1.1.3.

Duties of the operator:...........................................................................................2

1.1.4.

Using the machine.................................................................................................3

1.1.5.

Checkups, maintenance, service and repair...........................................................3

1.2.

Transporting the machine....................................................................................................3

1.3.

Prohibited activities.............................................................................................................4

1.4.

Hygienic instructions...........................................................................................................4

1.5.

Ecological instructions ........................................................................................................4

1.6.

Liquidating the machine at the end of its useful lifetime ...................................................4

1.7.

Safety instruction for work with B-300R Universal Grinder ..............................................4

1.8.

Hygienic information ..........................................................................................................5

1.9.

List of safety labels used on the machine............................................................................5

2. TECHNICAL DATA AND DESCRIPTION OF THE MACHINE.............6

2.1.

Description of the machine..................................................................................................6

2.2.

Technical specifications ......................................................................................................6

2.3.

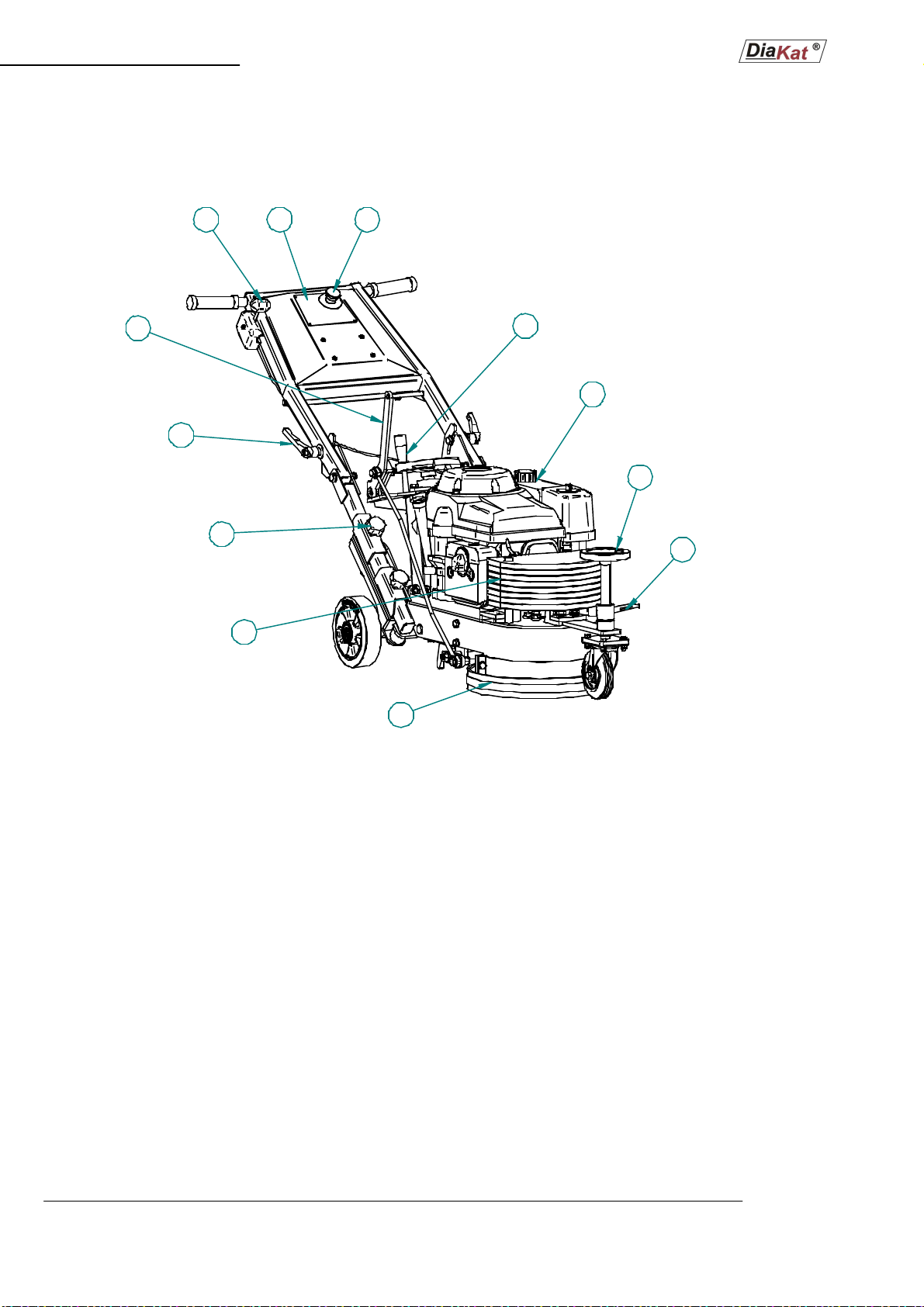

Primary operative parts of the machine...............................................................................7

2.4.

Description and designation of tools...................................................................................7

2.5.

Mounting and dismounting of tool......................................................................................8

2.5.1.

Mounting of tool....................................................................................................9

2.5.2.

Dismounting of tool ............................................................................................9

3. BEFORE STARTING............................................................................9

3.1.

Visual check up of the machine state ..................................................................................9

4. WORKING WITH THE MACHINE .......................................................10

4.1.

Setting of the machine , start.............................................................................................10

4.2.

Working with the machine ................................................................................................10

4.3.

Switching off the machine.................................................................................................10

5. MAINTENANCE...................................................................................11

5.1.

Cleaning of the machine....................................................................................................11

5.2.

Checking screw joints .......................................................................................................11

5.3.

Engine maintenance ..........................................................................................................11

5.4.

Tool maintenance..............................................................................................................11

5.5.

Inspection of tautness of V belts. ......................................................................................11

6. CONDITIONS OF GUARANTEE.........................................................12