en0100.ss550sTOC.fm

&217(176

&RQWHQWV 3DJH &RQWHQWV 3DJH

6DIHW\LQVWUXFWLRQV

.................................................... 5

Welding ................................................................ 6

Modifying the equipment..................................... 6

6\VWHPRYHUYLHZ

....................................................... 7

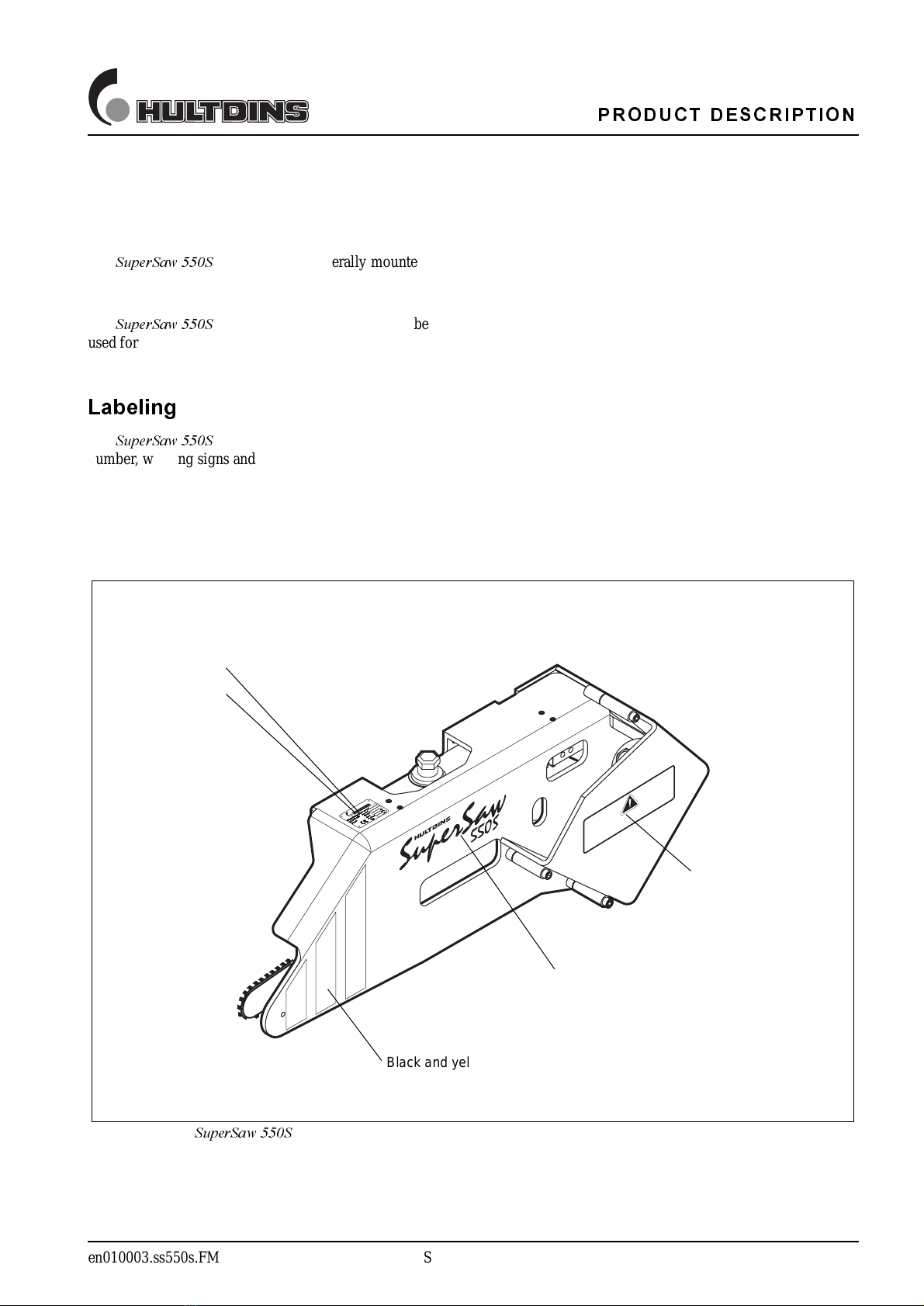

3URGXFWGHVFULSWLRQ

.................................................. 9

7HFKQLFDOGDWD

......................................................... 11

SuperSaw 550S / TL..................................... 11

SuperSaw 550S / SG .................................... 13

Special tools ....................................................... 15

Air Pump ...................................................... 15

Combi Wrench.............................................. 15

Standard tools..................................................... 16

Wrenches...................................................... 16

Allen keys..................................................... 16

Hydraulic Diagram SuperSaw 550S/TL ............ 17

Hydraulic Diagram SuperSaw 550S/SG............ 18

)XQFWLRQDOGHVFULSWLRQ

........................................... 19

Saw activated chain tensioning.......................... 19

Pressure line feed out system............................. 20

Lubrication system............................................. 21

$VVHPEO\DQG'LVDVVHPEO\

................................... 22

Installing the SuperSaw 550S on TL grapples... 22

Installing the SuperSaw 550S on SG grapples... 24

Adjusting chain tension pressure ....................... 27

Adjusting saw bar feed out pressure.................. 28

Adjusting saw bar retraction .............................. 29

Charging the air tank.................................... 29

Depressurizing the air tank........................... 30

Replacing Accumulator...................................... 31

Refilling lubrication oil tank.............................. 32

Bleeding chain tension system........................... 33

Saw activated tensioning.............................. 33

Constant pressure activated tensioning ........ 34

Bleeding chain lubrication system ..................... 34

Replacing saw chain........................................... 35

Replacing saw bar.............................................. 36

Replacing bar holder.......................................... 37

Manual chain tensioning.................................... 38

Replacing broken guide screw........................... 39

Replacing piston seals........................................ 40

Replacing piston rod seal................................... 41

Testing function of check valve ......................... 42

Replacing tension- and lub. oil hoses................. 42

0DLQWHQDQFHLQVWUXFWLRQV

...................................... 43

Regular maintenance.......................................... 43

Daily maintenance........................................ 43

Every 250 hours of operation....................... 43

Every year of operation................................ 43

Lubrication ................................................... 44

Fastener joints and hydraulic hoses.............. 44

The first month of operation .............................. 44

Fasteners....................................................... 44

7URXEOHVKRRWLQJ

...................................................... 45

SuperSaw 550S............................................. 45

SuperCut....................................................... 46