en_ss651TOC.fm SuperSaw 651S

CONTENTS

Contents Page Contents Page

Safety instructions.................................................... 4

Welding ................................................................ 5

Modifying the equipment..................................... 5

Chain shot hazard................................................. 5

Operator and bystander safety........................ 5

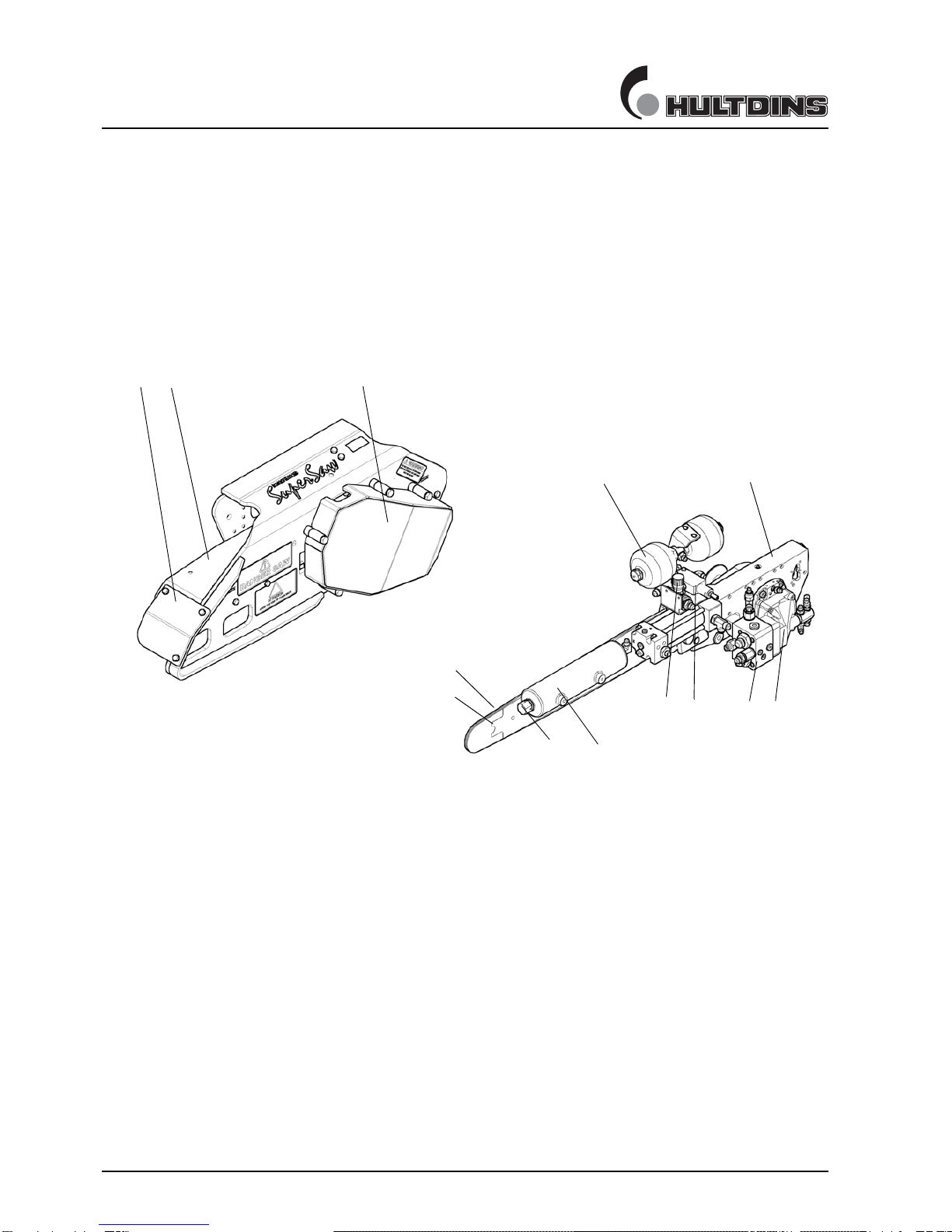

Product description.................................................. 6

Main parts, Grapple saw ...................................... 6

Lubrication oil tank.............................................. 7

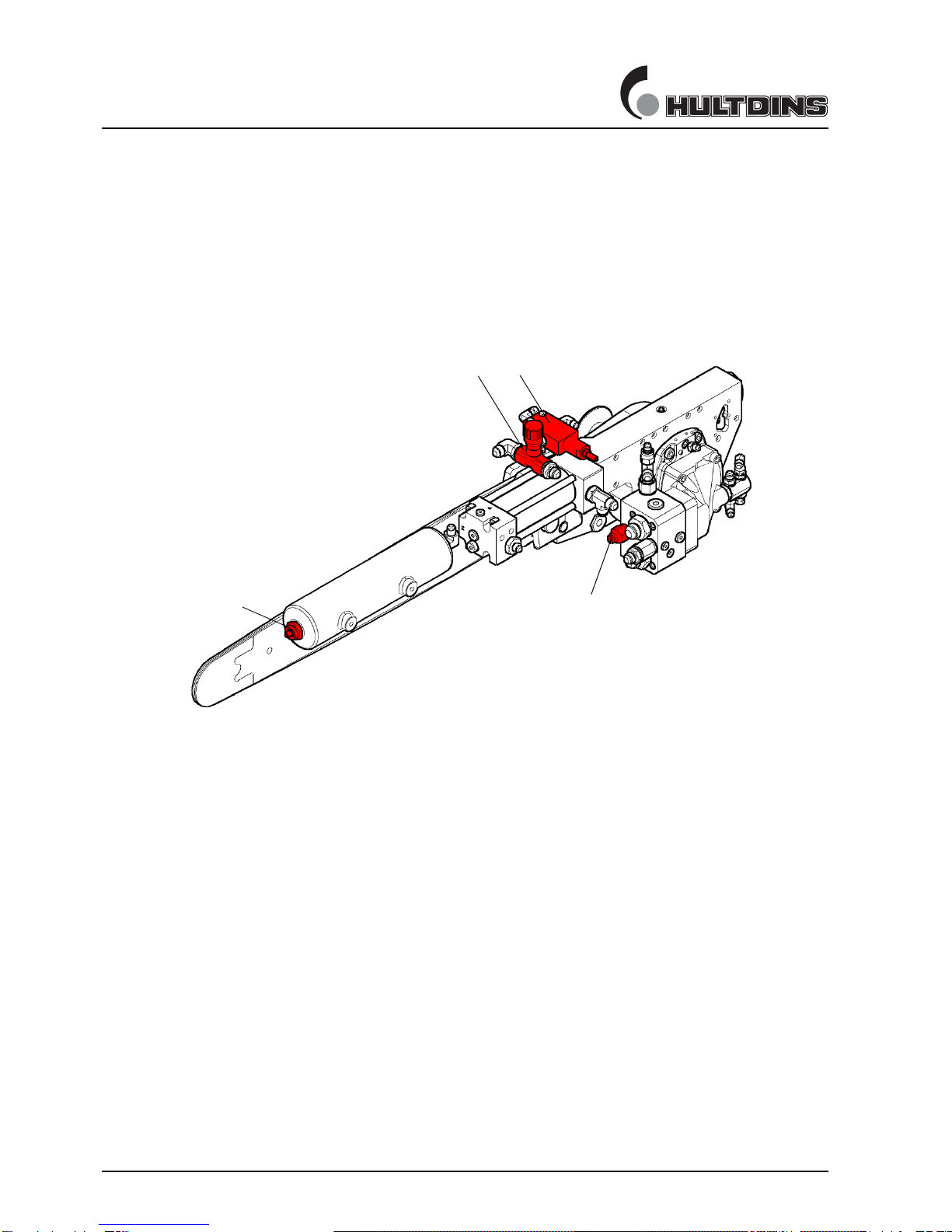

Adjustment valves, Grapple saw.......................... 8

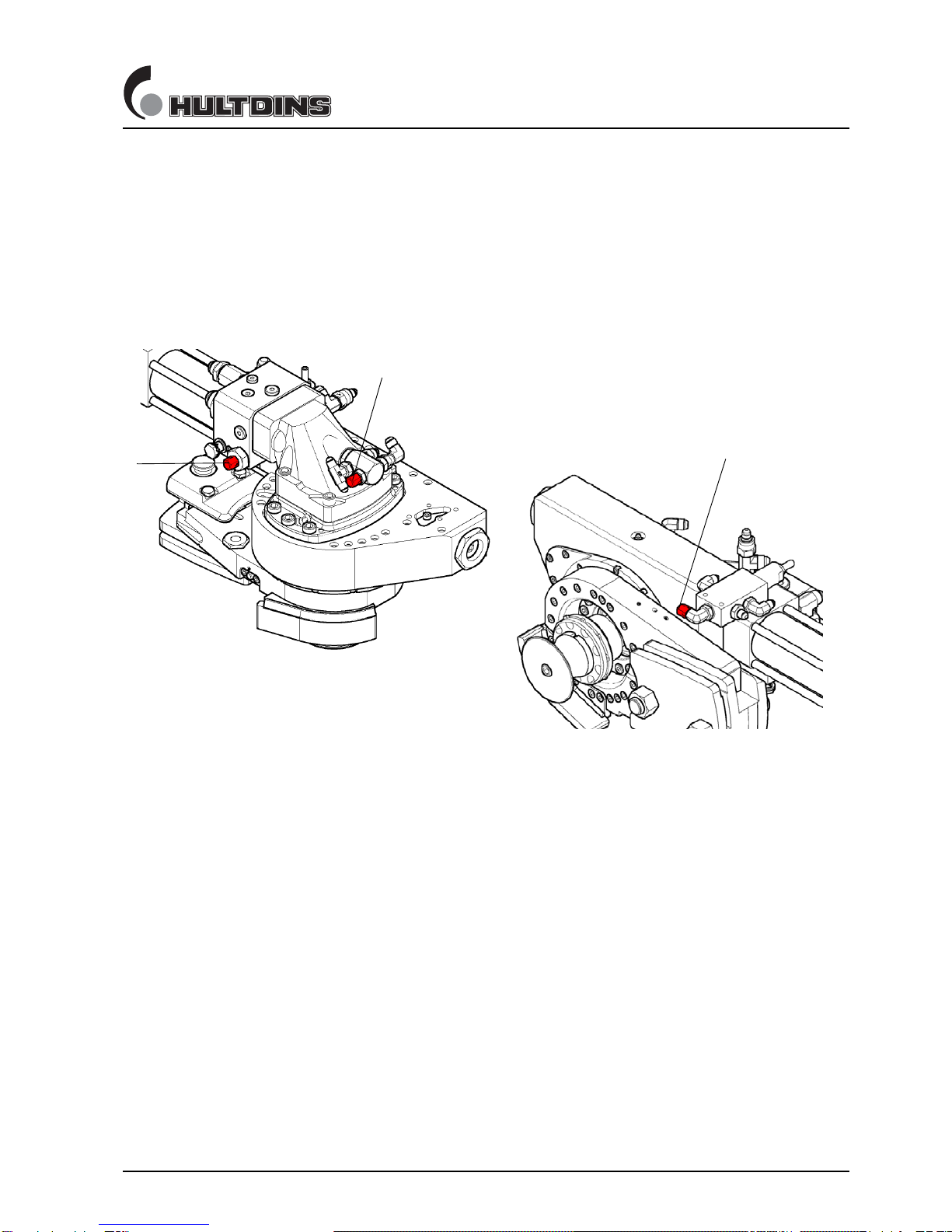

Hydraulic pressure test points.............................. 9

SuperCut 300...................................................... 10

Labeling.............................................................. 11

Technical Data........................................................ 12

SuperSaw 651S - 40cc ....................................... 12

SuperSaw 651S - 60cc ....................................... 13

Rotator bracket HD............................................ 14

Special tools....................................................... 15

Hydraulic diagram SuperSaw 651S................... 17

Functional description........................................... 18

Chain lubrication system.................................... 18

Installation.............................................................. 19

Where to install the grapple saw? ...................... 19

Installing HD rotator bracket ............................. 20

Hydraulic installation......................................... 21

Initial upstart.......................................................... 22

Saw motor upstart .............................................. 22

Adjusting saw bar feed out pressure .................. 23

Adjusting saw bar feed out................................. 24

Adjusting saw bar retraction .............................. 24

Adjusting chain tension pressure ....................... 25

Bleeding the chain tension system..................... 26

Procedures .............................................................. 27

Replacing saw chain........................................... 27

Replacing saw bar.............................................. 28

Replacing bar holder .......................................... 29

Replacing drive sprocket.................................... 30

Refilling chain lubrication oil ............................ 31

Maintenance instructions...................................... 32

Regular maintenance.......................................... 32

Daily maintenance........................................ 32

Lubrication ................................................... 33

Fastener joints and hydraulic hoses.............. 33

The first month of operation .............................. 33

Fasteners....................................................... 33