HUNTER

DIESEL ENGINE

An engine owners manual is supplied

with your boat and should be read

thoroughly. The manual contains

technical specifications, running instruc-

tions and maintenance schedule on

lubricants and fluids. For long engine life,

follow routine maintenance schedules.

You should check engine oil,

transmission fluid, and coolant levels.

Water, rust, scale and dirt will cause

serious damage to the injectors on diesel

engines. You should check your filters

frequently and change when necessary.

If you start your engine, run it a

minimum of 15 minutes to bring it up to

operating temperature. This insures that

any condensation is evaporated. Your

engine should "run-out", at 3/4 throttle,

at least once a month to clean out carbon

build up and moisture.

STARTING:

1.

Visually check engine compartment

to see that the throttle linkage, shifting

controls, electrical connections and fuel

lines are properly secured.

2.

BEFORE EACH START check oil

in engine and transmission.

3.

Insure that engine shut-off cable is

properly secured and operating.

4.

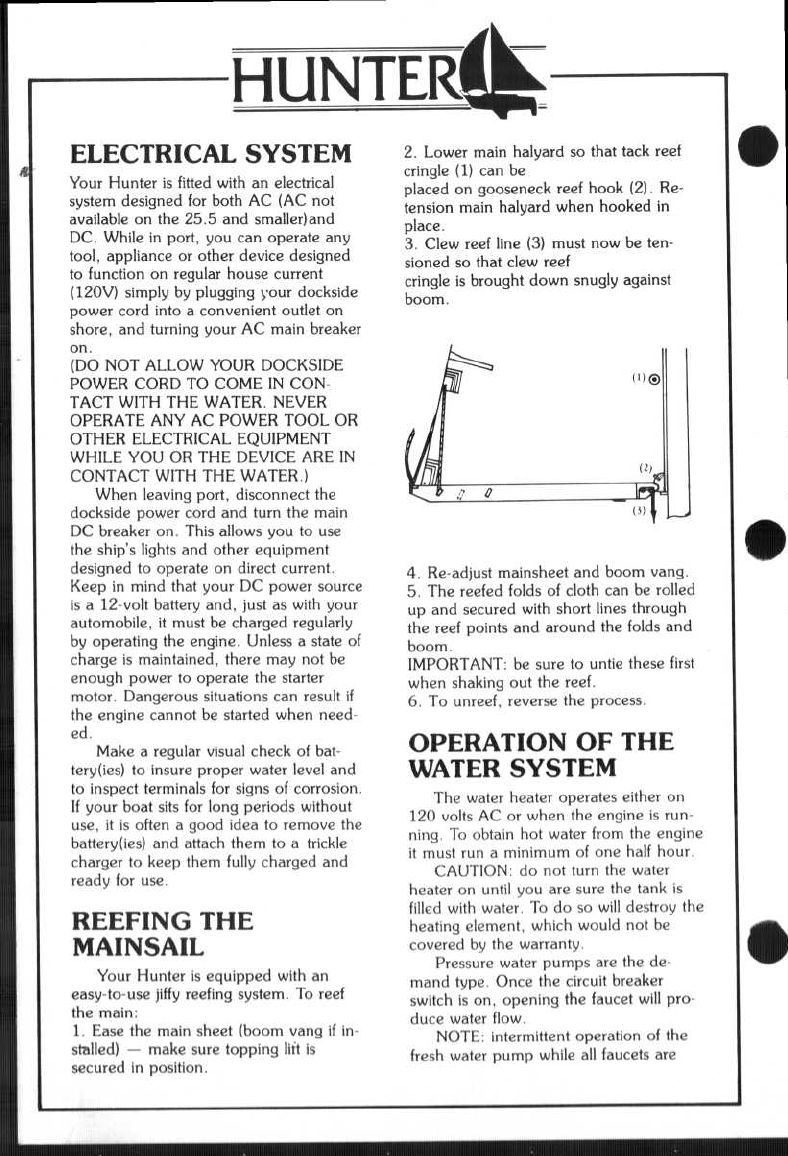

Place the shift lever (Fig. la) in the

neutral position.

5.

Move the throttle or "fuel" lever

(Fig. lb) forward to approximately the

half speed position.

6.

Insert the starter key and turn to

the "ON" position.

7.

Press the starter button and hold

until engine starts, then release The buzzer

and/or light should then go off.

8.

Back the throttle off to an idle

position (700-800 rpm) allow cold engine

to warm up a minimum of 5 minutes.

9.

Check to see that the lube oil

pressure warning light and the charge

lamp go off.

If any of the warning lamps do not go

off above 1000 rpm, the engine is

malfunctioning and should be stopped

immediately. Consult your nearest engine

dealer.

NOTE: To stop engine at any time,

pull "fuel" lever all the way aft (Fig. lb).

Before stopping, however, it is a good

idea to idle the engine in neutral for

about 5 minutes, then race it in the full

throttle position for a moment, then

return to idle and stop the engine.

CAUTION: DO NOT TURN SAFETY

MAIN SWITCH TO "OFF' WHILE

ENGINE IS RUNNING. THIS CAN

SERIOUSLY DAMAGE THE ALTER-

NATOR.

MOTORING:

When engine is warm, you may

move the "shift" lever either forward to

go ahead or aft to move in reverse (Fig.

la).

CAUTION: your rigging will conduct

electricity. Always check for overhead

high tension wires before proceeding.

Once clear, you may increase your speed

in a reasonable and safe manner as

desired.

IMPORTANT: do not shift from for-

ward to reverse or back without first

lowering engine rpm.