SAFETY

Operating Safely

• Be sure all drives are in neutral and parking brake is engaged before

starting engine. Only start engine from the operator’s position.

• Slow down and use extra care on hillsides. Be sure to travel in the

recommended direction on hillsides. For this machine, drive across

hillsides, not up and down.Turf conditions can affect the machine’s

stability. Use caution while operating near drop-offs.

• Slow down and use caution when making turns and when changing

directions on slopes.

• Never operate with the shields, or other guards, not securely in

place. Be sure all interlocks are attached, adjusted properly, and

functioning properly.

• Do not change the engine governor setting or overspeed the engine.

Operating the engine at excessive speed can increase the hazard of

personal injury and machine damage.

• Stop on level ground, engage parking brake, close deflectors, and

shut off engine before leaving the operator’s position for any reason.

• Stop equipment and inspect impeller if an abnormal vibration occurs.

Make necessary repairs before resuming operations.

• Keep hands and feet away from the Intake and discharge.

• Look behind and down before backing up to be sure of a clear path.

• Never carry passengers and keep pets and bystanders away.

• Slow down and use caution when making turns and crossing roads and

sidewalks. Close deflectors if not blowing.Watch for traffic when operating

near or crossing roadways.

• Be aware of the blower discharge direction and do not point it at anyone.

• Do not operate the machine while under the influence of alcohol or drugs.

• Use care when loading or unloading the machine into or off of a trailer or truck.

• Use care when approaching blind corners, shrubs, trees, or other objects

that may obscure vision.

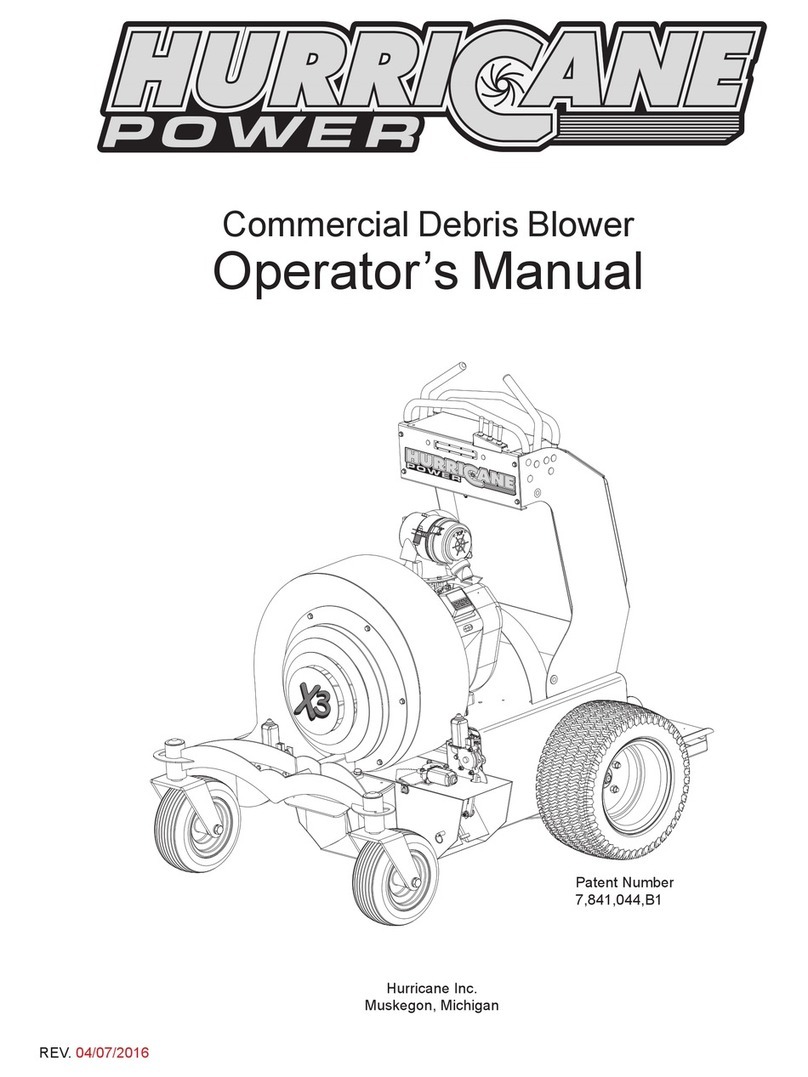

• Inspect machine before you operate. Be sure hardware is tight. Repair or

replace damaged, badly worn, or missing parts. Be sure guards and

shields are in good condition and fastened in place. Make any necessary

adjustments before you operate.

• Before using, always visually inspect to see that the impeller, its bolt, and

blower assembly are not worn or damaged. Replace worn or damaged

impeller and bolt.

• Keep safety labels visible when installing accessories and attachments.

• Do not wear radio or music headphones. Safe service and operation

require your full attention.

• When machine is left unattended, stored, or parked, remove the key.

4