OPERATING INSTRUCTIONS continued:

9. After using spreader in freezing conditions make sure impeller housing is drained.

10. Wash tank inside and out each time work is finished. This will increase the life of the tank by many years. See item 6 of

Safety instructions

11. Do not drive on public roads after dusk unless equipped with lights required by Department of Transportation in your area.

12. Remove wheels annually and grease wheel bearings.

13. Because manure smells, many farmers have made unfriendly neighbours. If in a residential area a manure injector is a

recommended option to bury the smell.

14. Much of the fertilizer value of manure is lost when exposed to air. Getting the manure covered quickly is a very important

part of spreading manure.

15. If rustproof coating on interior shows signs of deterioration, have interior repainted. This can be done with a roller or

brush. This helps to increase the life of your spreader. It is a valuable maintenance procedure.

SAFETY INSTRUCTIONS:

Do not operate this machine until you fully understand the safe operating practices.

1. Make sure all moving parts are shielded to prevent coming in contact with loose clothing.

2. Keep children clear; do not let children or any person(s) ride the spreader at anytime.

3. Do not support loaded spreader on tongue jack.

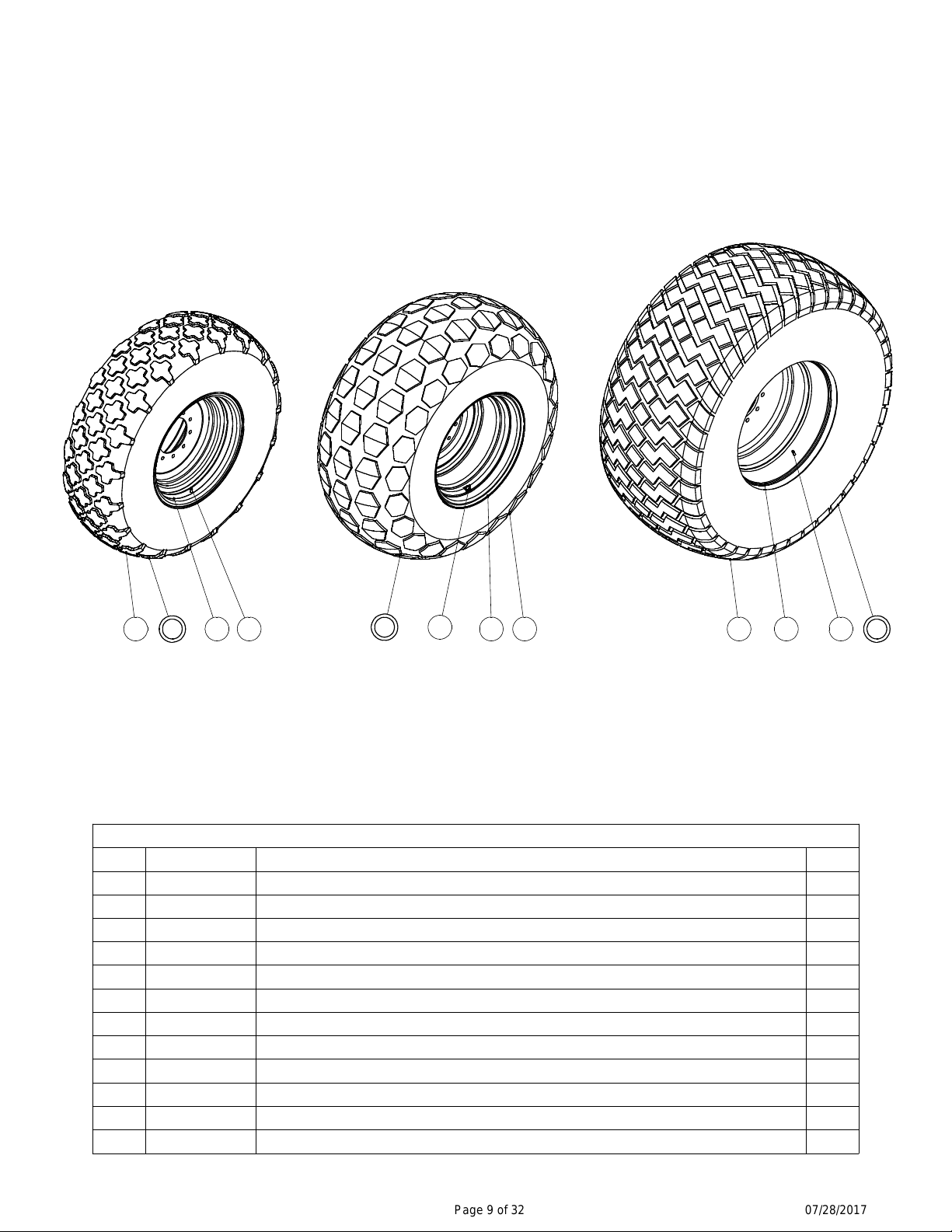

4. Keep tire pressure to recommended pressure at all times. Recommended tire pressure being:

Size Description PSI KPA

40 x 14 Airplane Tires 55 379

44 x 16 Airplane Tires 55 379

47 x 18 x 18 Airplane Tires 55 379

50 x 20 x 20 Airplane Tires 55 379

16.5L x 16.1 Implement Tires 35 241

21.5L x 16.1 Implement Tires 35 241

18.4L x 26 Turf Tires 30 207

23.1L x 26 Turf Tires 24 166

28L x 26 Turf Tires 24 166

30.5L x 32 Turf Tires 35-40 241

35.5L x 32 20 ply Turf Tires 35 241

18L x 22.5 Truck Tires 65 448

23.5L x 25 Loader Dozer Tires 55 379

5. Keep wheel bolts torqued to the recommended torque at all times. (Check Daily)

Wheel Bolt Size Ft/Lbs Torque (Dry) Ft/Lbs. - Oiled Meter/Kg - Torque Dry Meter/Kg - Oiled

9/16 – 18 NF GR. 5 120 90 16.59 12.44

5/8 – 18 NF GR. 8 240 180 33.18 24.89

3/4 – 16 NF GR. 8 420 310 58.07 42.86

6. Never enter a tanker without special breathing equipment to supply oxygen. Manure gases can kill instantly. One

breath of Hydrogen Sulphide can kill.

7. When repairing hydraulic hoses, always relieve pressure in hose. Always wear safety glasses while working on

spreader.

8. Caution – disc brakes will not release until valve lever is held momentarily in opposite position. This will relieve

pressure in brake line. Do not put in float position, they will not release. (Rule does not apply to Husky Manure

Spreaders equipped with a Knott Brake System)