GENERAL SAFETY PRECAUTIONS

English

–

5

Important Remember when going out onto

the ice:

• Never go out onto the ice alone.

• Always carry ice prods and other safety equipment on

the ice.

• Never go out onto ice if you are unsure of its strength.

Always test the ice with an ice-pike if you are

uncertain.

• Be aware that many factors affect the strength of the

ice, not just the thickness of the ice. For example, new

ice, spring ice, snow covered ice and sea ice can be

weak. Straits, points, open channels, shallows, etc.

are areas that can be weak even though the ice is

thick.

• Always inform someone of your whereabouts and

when you will be returning.

Personal protective equipment

HEARING PROTECTION

Wear hearing protection that provides adequate noise

reduction.

EYE PROTECTION

Protective goggles or a visor must be worn.

IMPORTANT!

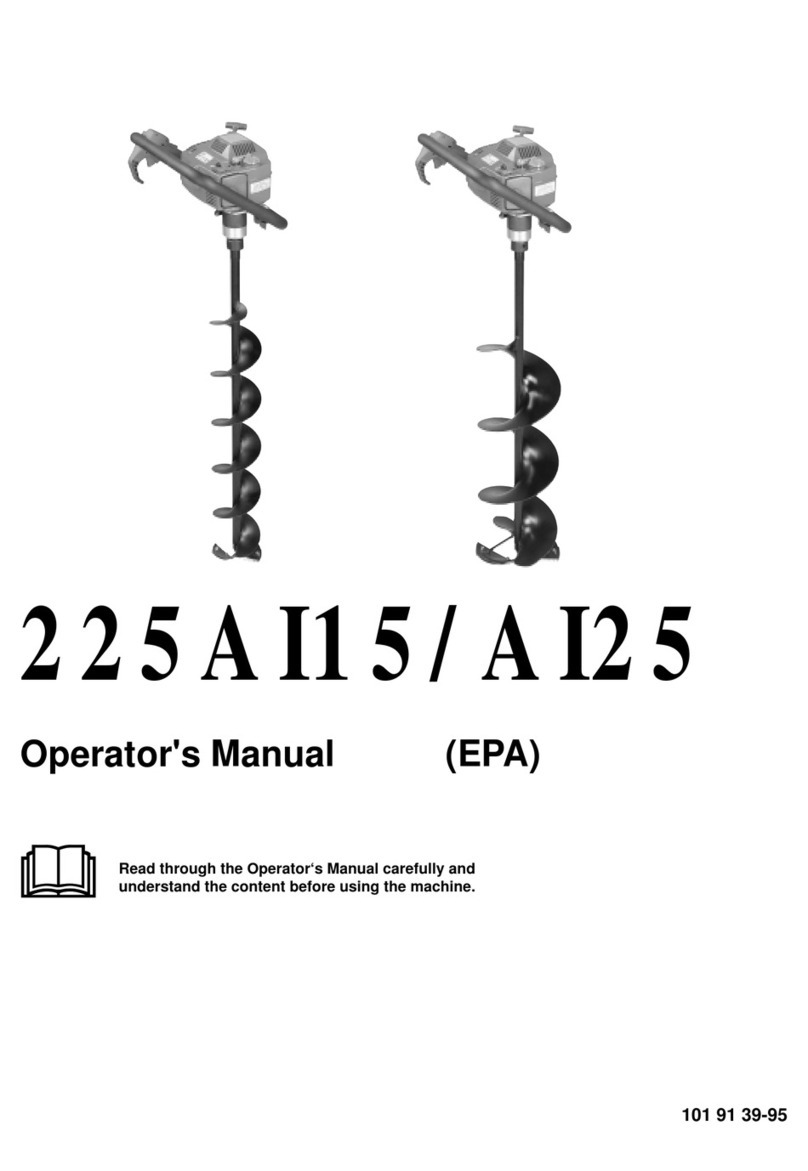

The machine is solely designed for drilling in ice.

Never use a machine that has been modified in any way

from its original specification.

Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the heading Personal protective equipment.

Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the heading Maintenance.

All covers and guards must be fitted before starting.

Ensure that the spark plug cap and ignition lead are

undamaged to avoid the risk of electric shock.

!

WARNING! The ignition system of this

machine produces an electromagnetic

field during operation. This field may

under some circumstances interfere with

pacemakers. To reduce the risk of

serious or fatal injury, we recommend

persons with pacemakers to consult

their physician and the pacemaker

manufacturer before operating this

machine.

!

WARNING! Running an engine in a

confined or badly ventilated area can

result in death due to asphyxiation or

carbon monoxide poisoning.

!

WARNING! Never allow children to use or

be in the vicinity of the machine. As the

machine is equipped with a spring-

loaded stop switch and can be started by

low speed and force on the starter

handle, even small children under some

circumstances can produce the force

necessary to start the machine. This can

mean a risk of serious personal injury.

Therefore remove the spark plug cap

when the machine is not under close

supervision.

IMPORTANT!

An ice drill is a dangerous tool if used carelessly or

incorrectly and can cause serious, even fatal injuries. It

is extremely important that you read and understand the

contents of this Operator’s Manual.

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.