English –7

SAFETY INSTRUCTIONS

General safety instructions

Transport and storage

•Store and transport the machine and fuel so that any leakage

or fumes do not risk coming into contact with sparks or

naked flames. For example, electric machines, electric

motors, electrical switches/power switches, heaters or the

like.

•When storing and transporting fuel approved containers

intended for this purpose must be used.

•When storing the machine for long periods the fuel tank

must be emptied. Contact your local petrol station to find

out how to dispose of excess fuel.

Fuel safety

•Always use a fuel container

with an anti-spill valve.

•Never fill the machine while

the engine is running.

Always stop the engine and

let it cool for a few minutes

before refuelling.

•Provide good ventilation

when filling or mixing fuel

(petrol and 2-stroke oil).

•Move the machine at least 3

m from the filling position

before starting.

•Never start the machine:

a)If you have spilt fuel on it.

Wipe up all spillage.

b)If you have spilt fuel on

yourself or your clothes.

Change your clothes.

c)If there is a fuel leak. Make

regular checks for leakage

from the fuel cap and the

fuel supply pipes.

Min. 3 m

(10 ft)

IMPORTANT INFORMATION

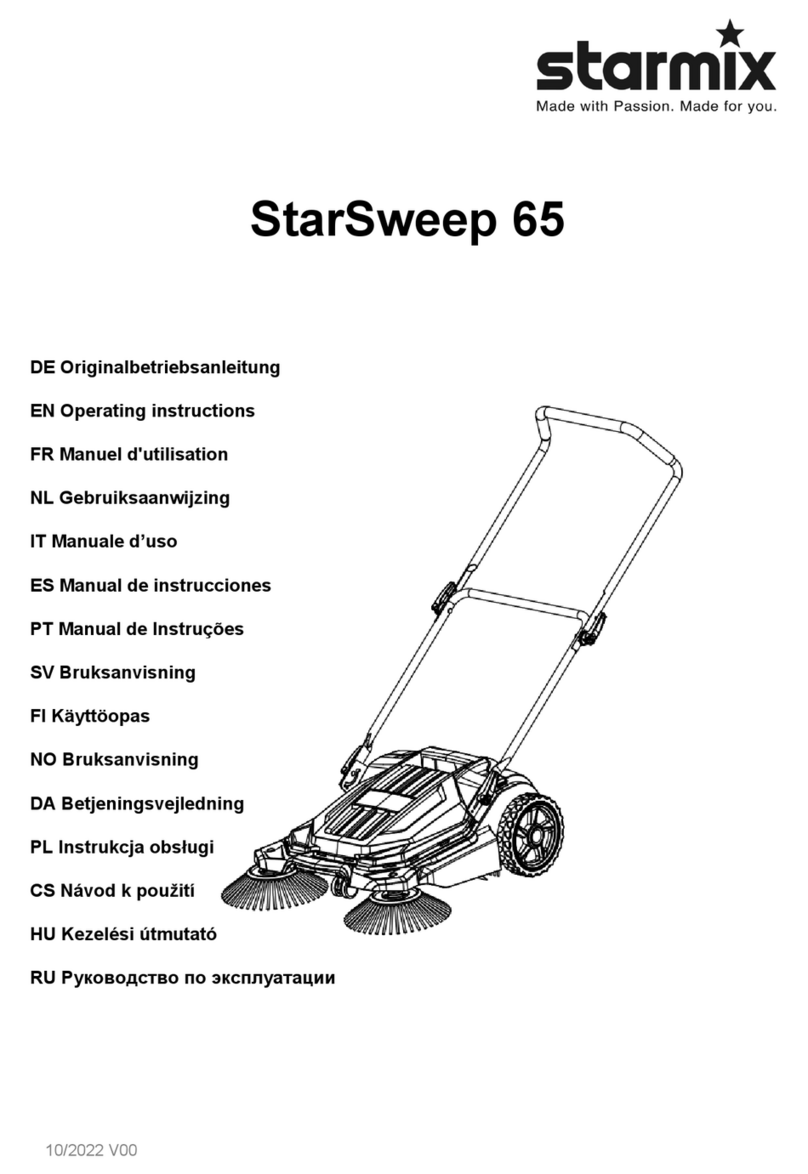

• The machine is only designed for sweeping lawns,

pathways, asphalt roads and the like.

• Never use the machine if you are tired, if you

have consumed alcohol, or if you are taking

medicines that can affect your sight, your

judgement or the control of your body.

• Use personal protective equipment. See the

section

“Personal protective equipment“.

•Never use a machine that has been modified so

that it no longer corresponds with the original

design.

•Never use a machine that is faulty. Follow the

maintenance, control and service instructions in

this Operator‘s Manual. Some maintenance and

service actions should be carried out by trained

and qualified specialists. See the chapter

“Maintenance“

.

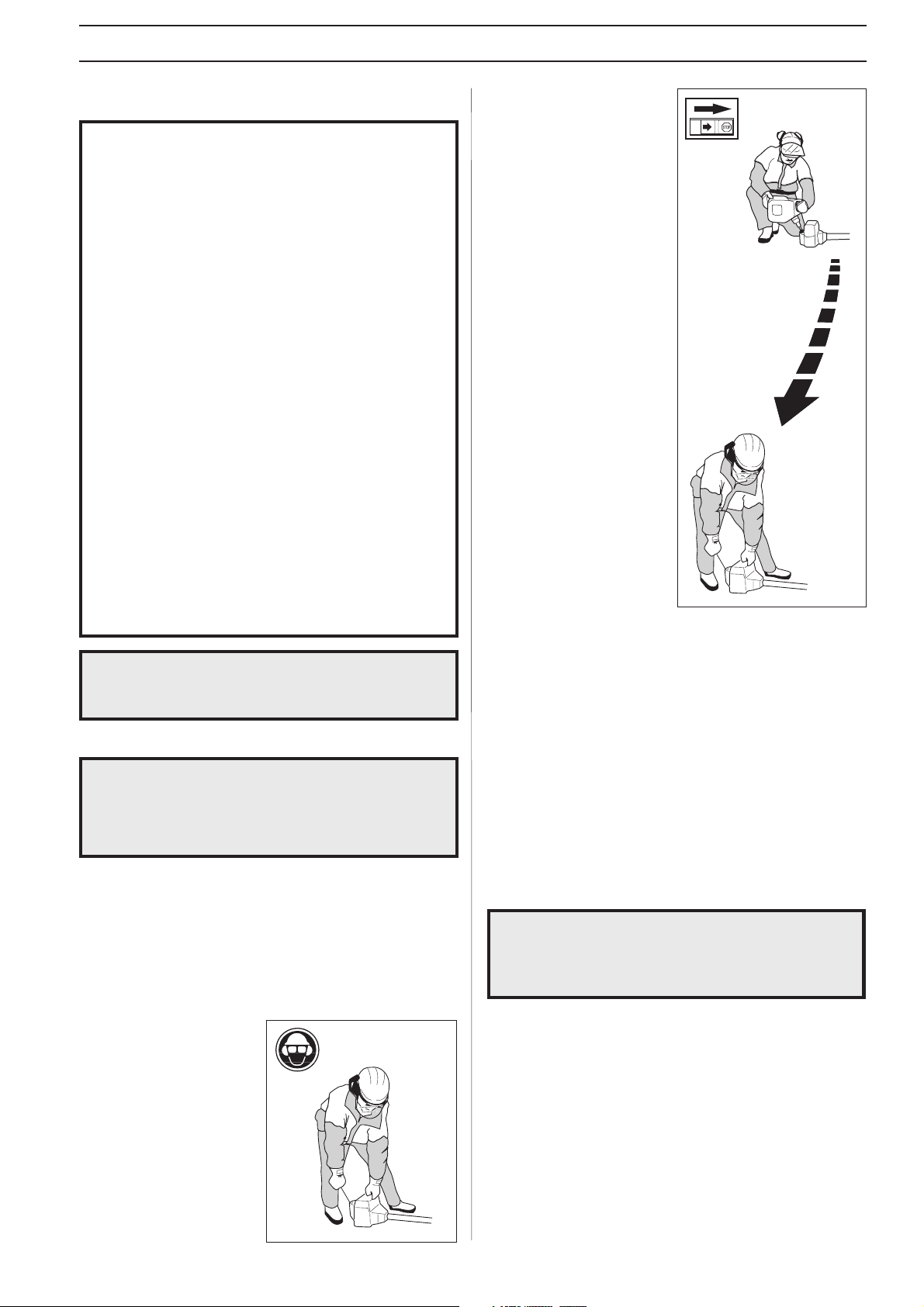

•All covers must be fitted before starting the

machine. Check that the spark plug cap and HT

lead are not damaged, otherwise you could get an

electric shock.

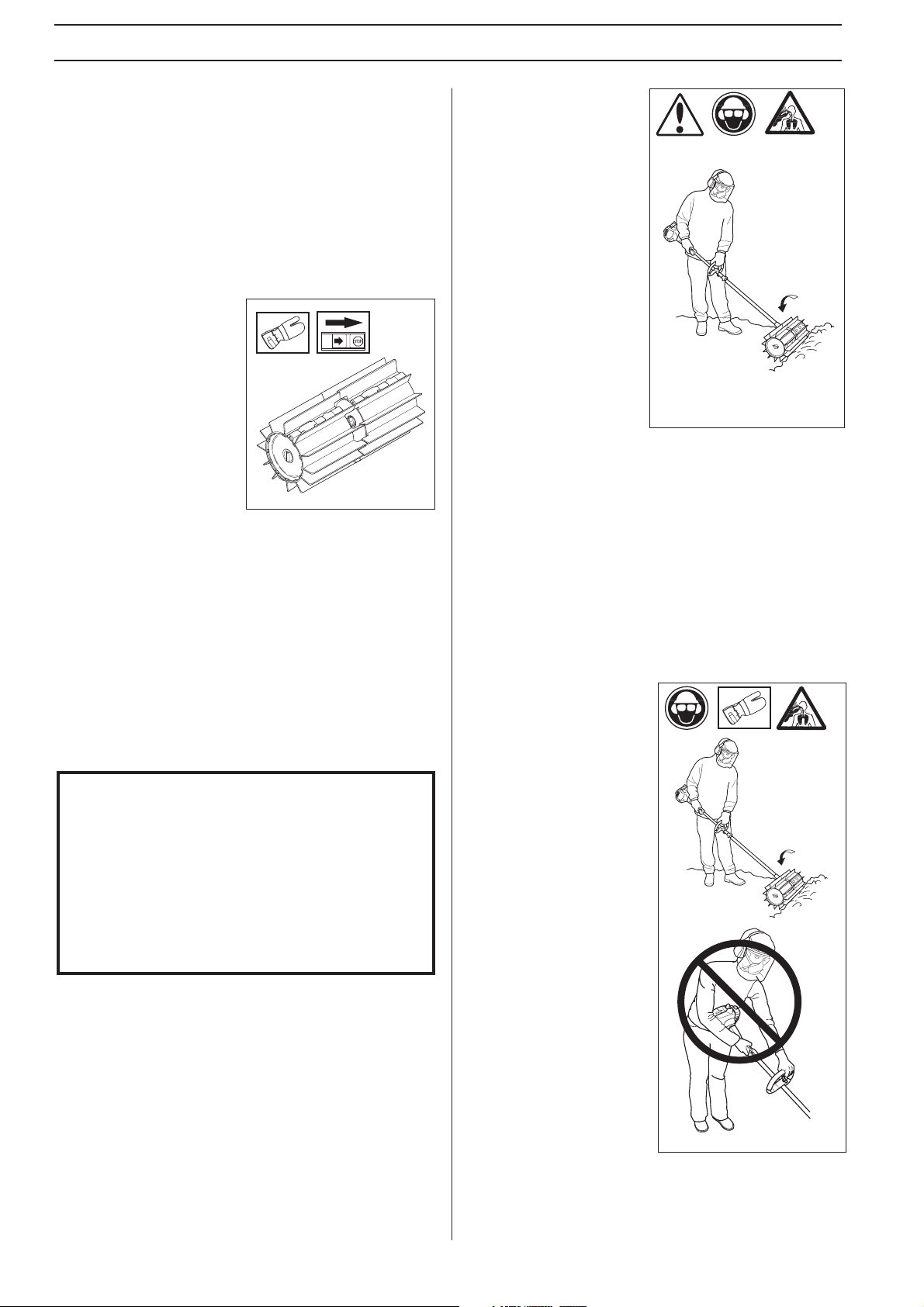

•The machine operator shall ensure, while

working, that no persons or animals come closer

than 15 metres (50 feet). When several operators

are working in the same area the safety distance

should be at least double tree length, however, at

least 15 metres (50 feet).

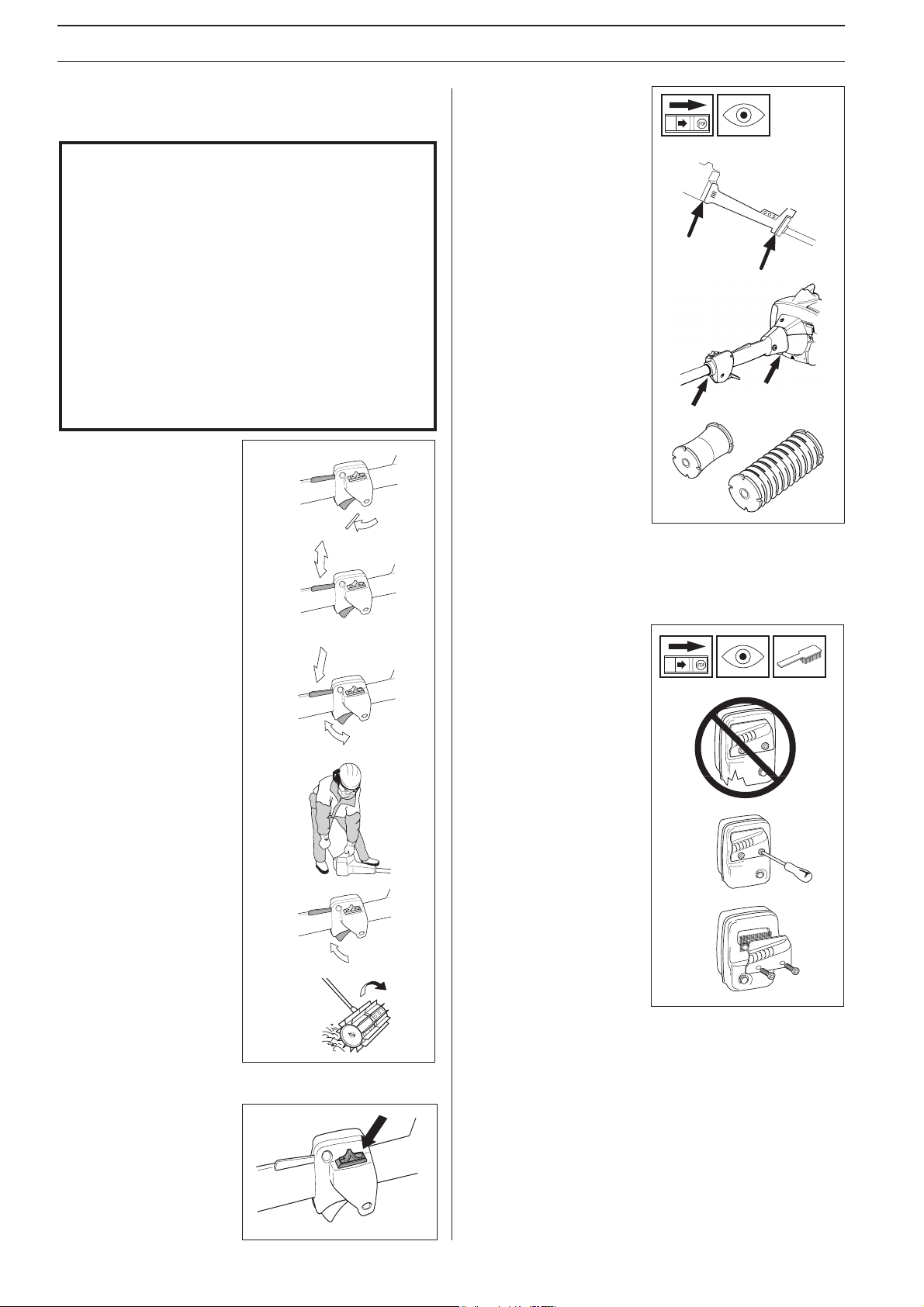

•The complete clutch cover with shaft must be fitted before

the machine is started, otherwise the clutch can become

loose and cause personal injury.

•Never start the machine indoors. Bear in mind the dangers

of inhaling the engine‘s exhaust fumes.

•Observe your surroundings and make sure that there is no

risk of people or animals coming into contact with the

sweeper rollers.

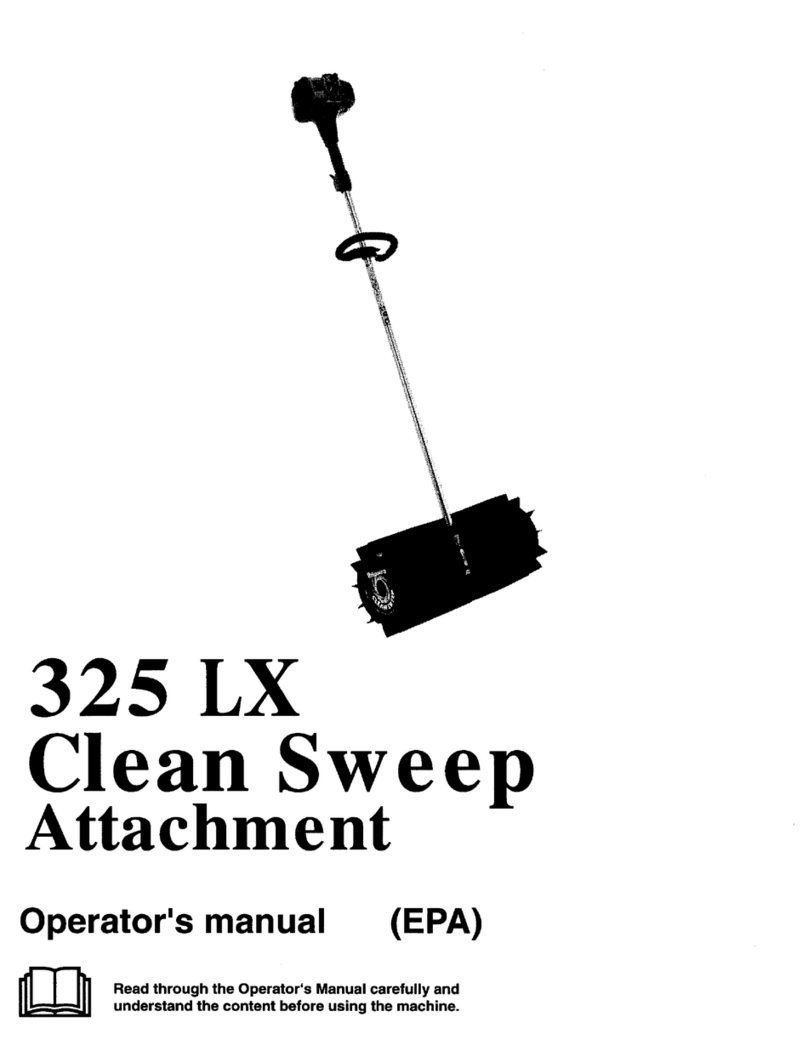

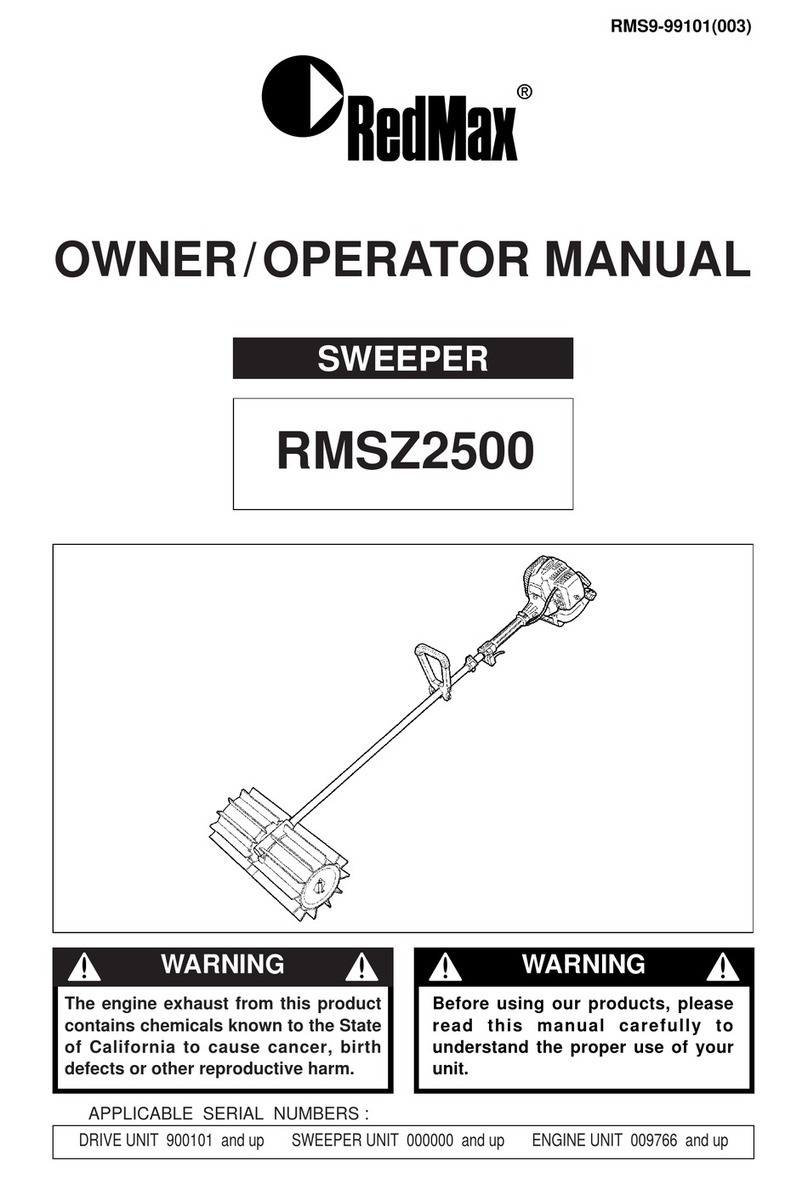

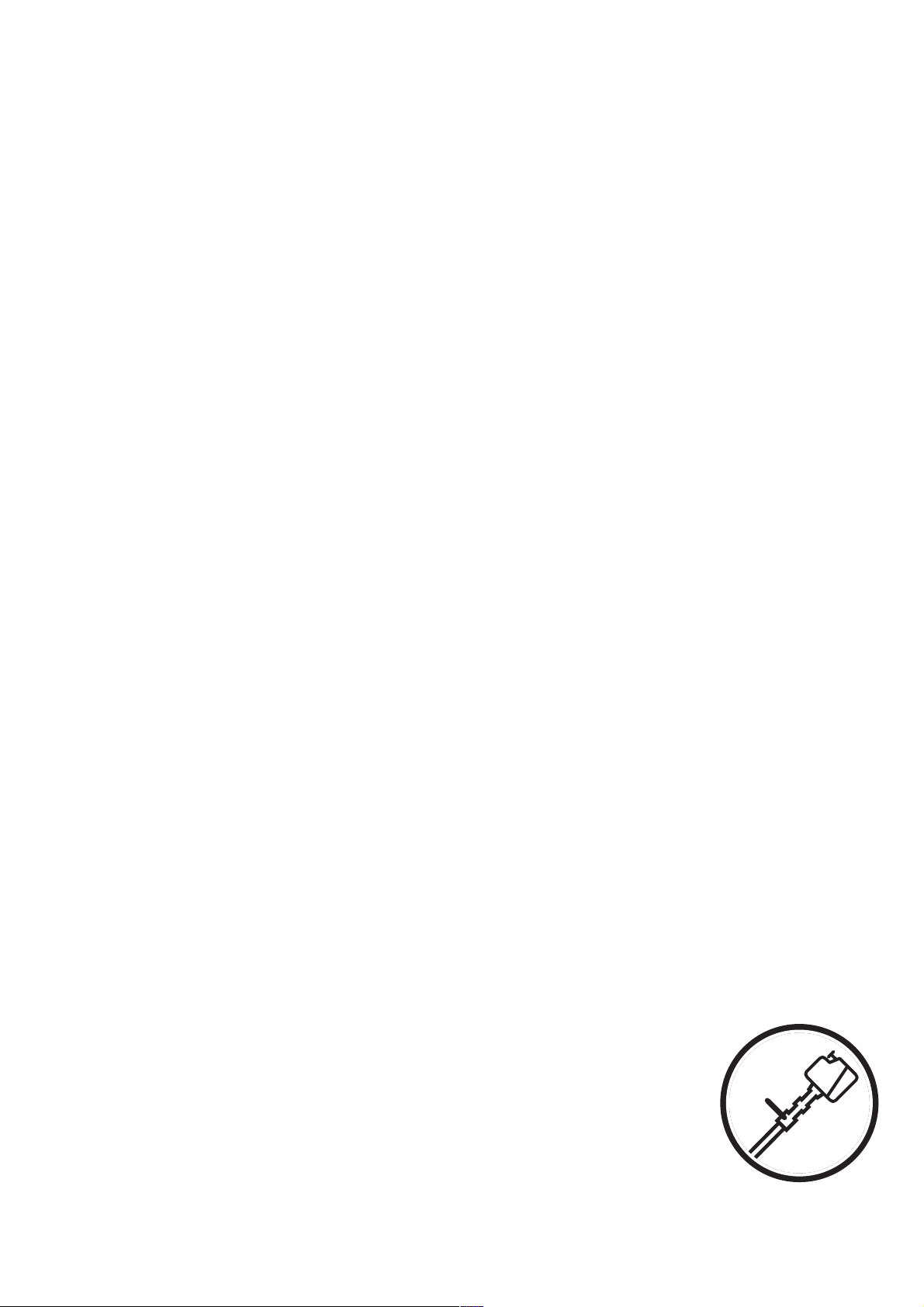

•Place the machine on the

ground, ensure the sweeper

rollers runs free of twigs

and stones. Push the

machine body towards the

ground using your left

hand. (NOTE! Not with

your foot). Grip the starter

handle with your right

hand and pull the

startercord.

!WARNING!

When the engine is started with the choke

in either the choke or start throttle positions

the sweeper rollers starts to rotate

immediately.

WARNING!

Exercise great care when handling fuel.

Bear in mind the risk of fire, explosions and

inhaling fumes.

!

Start

WARNING!

Faulty equipment increases the risk of

accidents.

!

Safety instructions regarding the

surroundings

•Never allow children to use the machine.

•Ensure no one comes closer than 15 metres when working.

•Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

Operator’s Manual.