Fitting the needle"

Choosing suitable thread and needle.

des 'when the needle works up and down ch rough che ma-

terial. On the opposite side of the needle, where the butt

is ground flat, the groove is shorter, and on this side the

thread forms the loop through which the shuttle is to pass"

Fitting the needle"

Vhen fitting the needle, place the needle bar in

its highesr position. Loosen the clamp screw and

push rhe needle as far into the needle bar slot as

it will go. See that the flat, ground shank of the

needle is placed against the bottom of the slot,

rrhus with the long groove in the ,reedle facing the

person who is sewing. Then tighten the screw"

One essential factor for rhe formation of stitches

is, thar the needle should be correctly fitted in the

machine. Never use a bent needle or one with

point throw away damaged needles inrmediately"

Choose thread to suit the material and &

needle to suit the thread.

A seam se{/n by machine should, as far as possible, blend

in wirh the weave of rhe n.raterial arad the thread should

therefore nor be so coarse so as to prevent the stirches being

concealed in the fabric. The under thread should prefcr-

ably be one number finer than the upper, and should in anv

case not be thicker.

_,

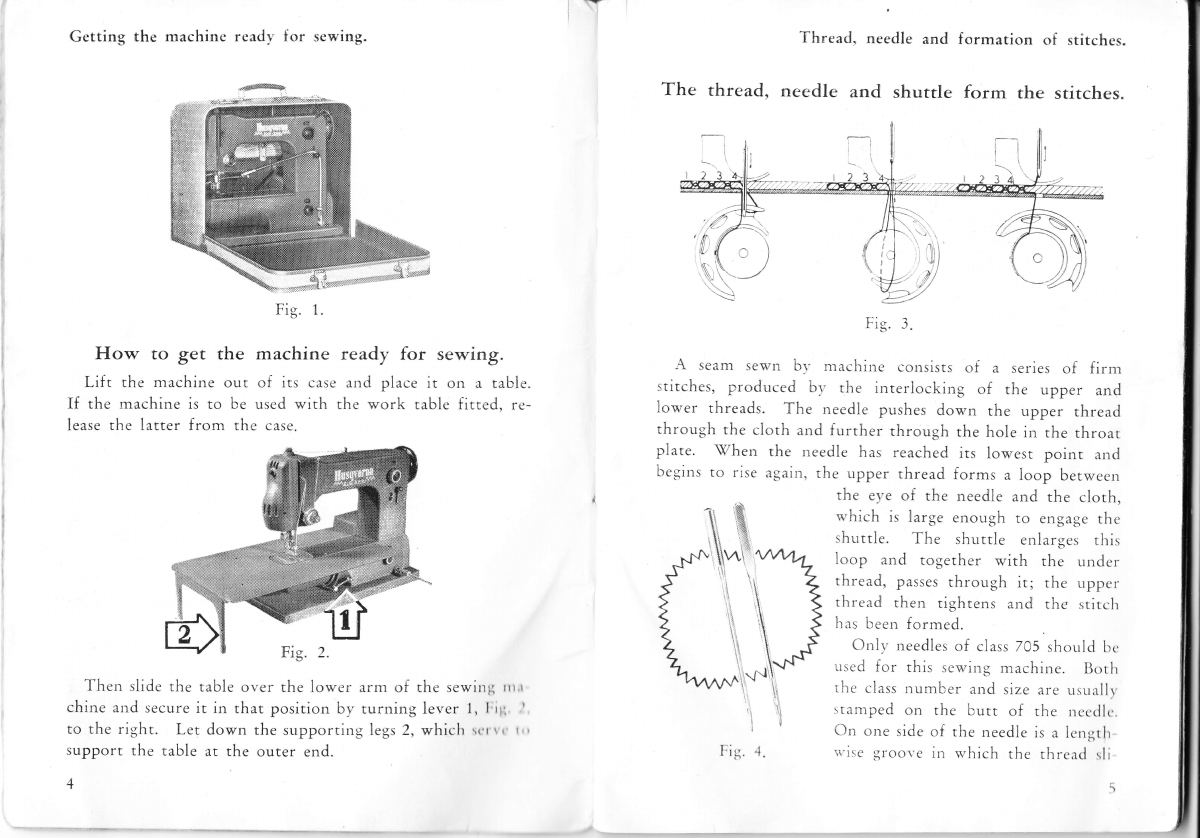

Desc;iption of ,material i No. a'd ki*d of thread Ncedle

ano narure or worK i i.\o.

_rl

; Fine work on very ,rhin ! ZOa sewing cotron

I materials i 200 embroi dery and

I I i----: - ^L.. --,

Thread and needle guide table.

The electric motor and knee-contr,ol"

Table of materials, needles and threads"

I I darning thread i

Ifli" nainsook, muslin, I ,r-150 sewing corcon Z

I lu*r, and silk r)u sewrng corcorl

32 machine silk i

i rto.kinerre ]so-zoo embroiderr- and i

darnins rhread

r___i______i

--i

. Silk stockinerre, table i OC-AC sewing corron I S

i li.,err, finer rnadapo- ]eg-lo ,rra.hlr. and ,pool i

I^---^ ^: r ^'r,.rt - -r-

lams, nainsook, r;tt ] silk II

and i

il

ffi

Fig. s.

a blunt I t oarn"rng thread I I

I

iHeavier si[ks,_ closer- l5C sewing corrorl , g I

", t i^r i ' . ]

woven rnadapolams, | 24-26 machine and spool

woollens and coarse silk

'l'lrc clectric rnotor and knee-control.

Make sut'(' rltlt tlre vo[Tage o[ rthe nloror ls rhe sanlc ,r.

rhat of thc lis,lrr ing circuic to which rir will be conncc(t.tl

lc

l

l

The tickness of the needle must be

thread; it must not be so coarse as to

materia[, rlor so fiire that the thread

rhrough the eye of the needle.

A soft, fine, even thread is suirable f'or

6

determined by t lr,'

leave rnarks irr t l',

Canlnot easiIv Ir.r,

use ira thc tlt.tr lttr r '

! i darning thread '

lCor.r. sheering, wool- ,tC sewing cotton

lcrr .urd corron 18-22 machine silk

I fabrics 30 embroidery and

darning rhiead

i towelling ifO-SC embroidery and