implants to speak to their physician and the medical

implant manufacturer before operating this product.

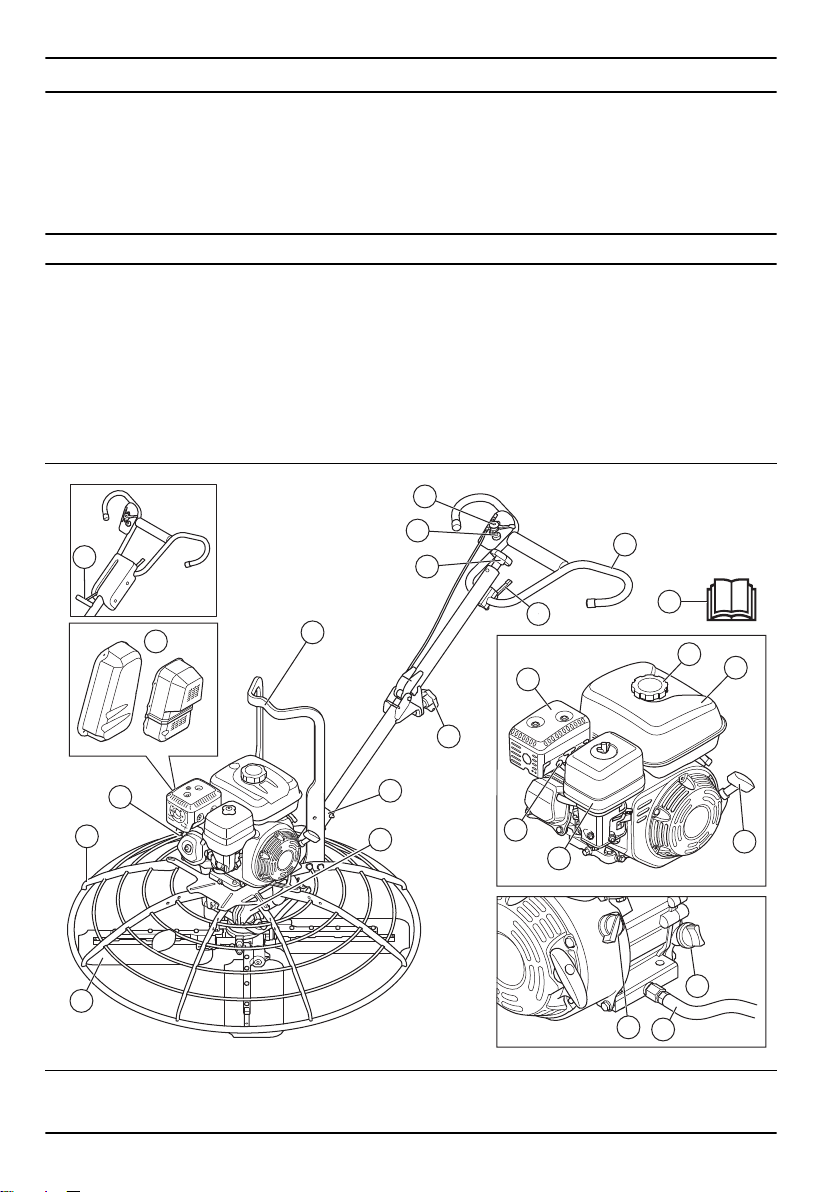

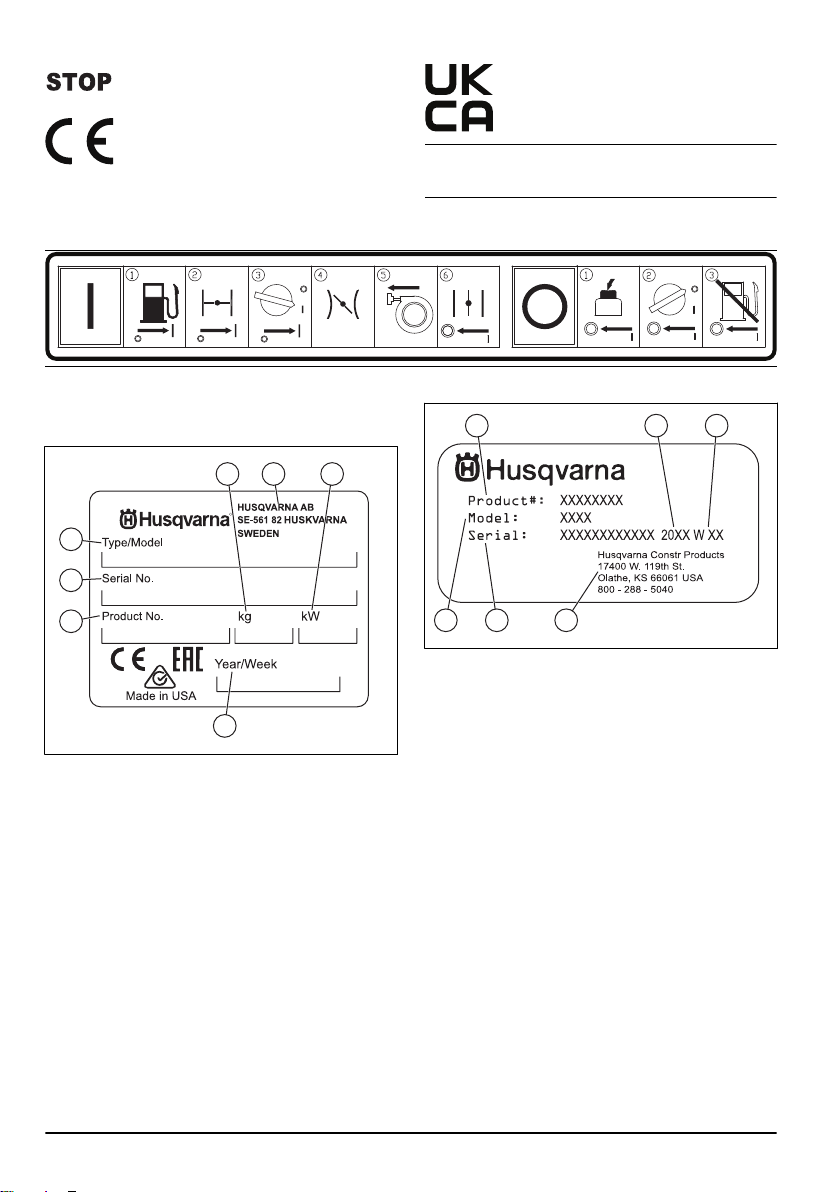

• Keep the product clean. Make sure that you can

clearly read signs and decals.

• Do not use the product if it is damaged.

• Do not make modifications to this product.

• Do not operate the product if it is possible that other

persons have made modifications to the product.

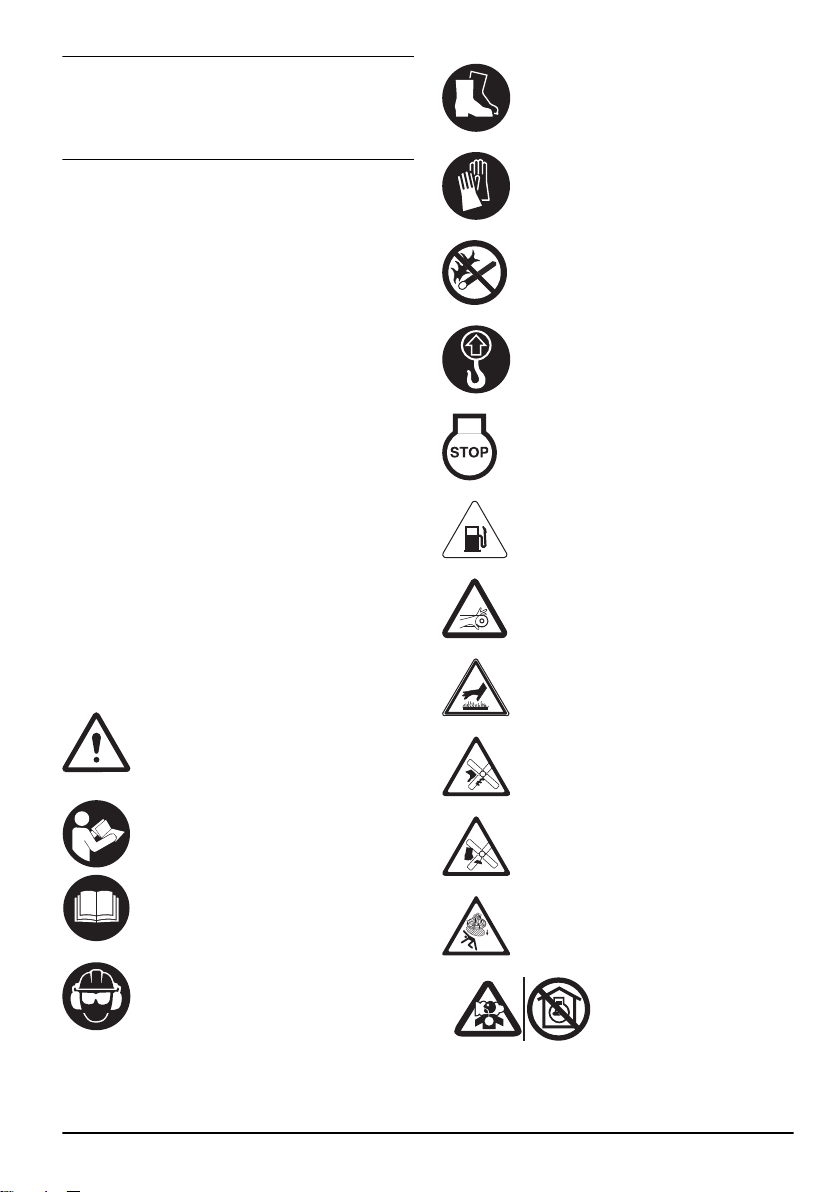

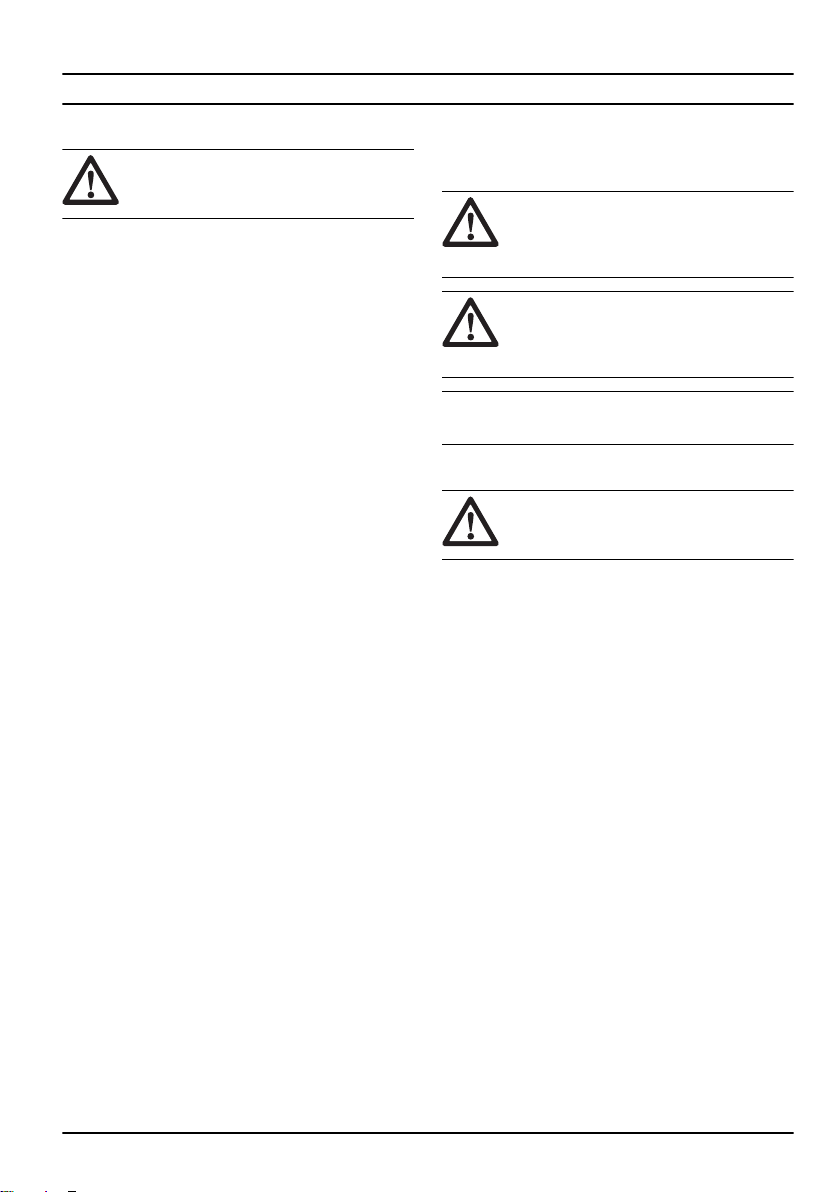

Vibration safety

WARNING: Read the warning

instructions that follow before you use the

product.

• During operation of the product, vibrations go from

the product to the operator. Regular and frequent

operation of the product can cause or increase the

degree of vibration-related injuries to the operator.

Injuries can occur in fingers, hands, wrists, arms,

shoulders, and/or nerves and blood supply or

other body parts. The injuries can be debilitating

and/or permanent, and can increase gradually during

weeks, months or years. Possible injuries include

damage to the blood circulation system, the nervous

system, joints, and other body structures.

• Symptoms can occur during operation of the product

or at other times. If you have symptoms and

continue to operate the product, the symptoms can

increase or become permanent. If these or other

symptoms occur, get medical aid:

• Numbness, loss of feeling, tingling, pricking,

pain, burning, throbbing, stiffness, clumsiness,

loss of strength, changes in skin color or

condition.

• Symptoms can increase in cold temperatures. Use

warm clothing and keep your hands warm and dry

when you operate the product in cold environments.

• Do maintenance on and operate the product as

given in the operator's manual to keep correct

vibration levels.

• Gently guide the product to do the work. Do not

push the product with force. Hold the product at the

handles securely, but make sure that you control

the product and operate it safely. Do not push the

handles into the end stops more than necessary.

• Keep your hands on the handle or handles only.

• Stop the product immediately if strong vibrations

suddenly occur. Do not continue the operation

before the cause of the increased vibrations is

removed.

Dust safety

WARNING: Read the warning

instructions that follow before you use the

product.

• Use of the product for operation on dry surfaces

different from those intended can cause increased

dust in the air. Inhalation of dust can cause serious

injury and permanent health problems. Silica dust is

regulated as harmful by several authorities. These

are examples of such health problems:

• The chronic or potentially fatal lung diseases

chronic bronchitis, silicosis and pulmonary

fibrosis

• Cancer

• Birth defects

• Skin inflammation

• Use correct protective equipment to decrease the

quantity of dust and fumes in the air and to decrease

dust on work equipment, surfaces, clothing and

body parts. Examples of controls are dust collection

systems and water sprays to bind dust. Decrease

dust at the source where possible. Make sure that

the equipment is correctly installed and used and

that regular maintenance is done.

• Make sure that the airflow is sufficient in the work

area.

• If it is possible, point the exhaust of the product

where it cannot cause dust to go into the air.

Exhaust fumes safety

WARNING: Read the warning

instructions that follow before you use the

product.

• The exhaust fumes from the engine contain carbon

monoxide which is an odourless, poisonous and very

dangerous gas. To breathe carbon monoxide can

cause death. Because carbon monoxide is odourless

and cannot be seen, it is not possible to sense it.

An early symptom of carbon monoxide poisoning is

dizziness, but sufficient quantity or concentration of

carbon monoxide may cause loss of consciousness,

especially in an enclosed space or area without

adequate ventilation.

• Exhaust fumes also contain unburned hydrocarbons

including benzene. Long-term inhalation can cause

health problems.

• Exhaust fumes that you can see or smell also

contain carbon monoxide.

• Do not use a combustion engine product indoors or

in areas that do not have sufficient airflow.

• Do not breathe the exhaust fumes.

• Make sure that the airflow in the work area is

sufficient. This is very important when you operate

the product in trenches or other small work areas

where exhaust fumes can easily collect.

Noise safety

WARNING: Read the warning

instructions that follow before you use the

product.

61452 - 003 - 30.01.2023