ELECTRICAL SPECIFICATIONS FD25 FUSE ONLY FD25/FD40 FUSE ONLY UPGRADABLE TO SOLENOID

ACTUATOR

Nominal voltage N/A

Power N/A

and FDCB contactors

1mA…500mA,

5VDC…48VDC 1mA…500mA, 5VDC…48VDC

Blade closure time

Blade opening time

Manual

Degree of protection IP 42 IP 42

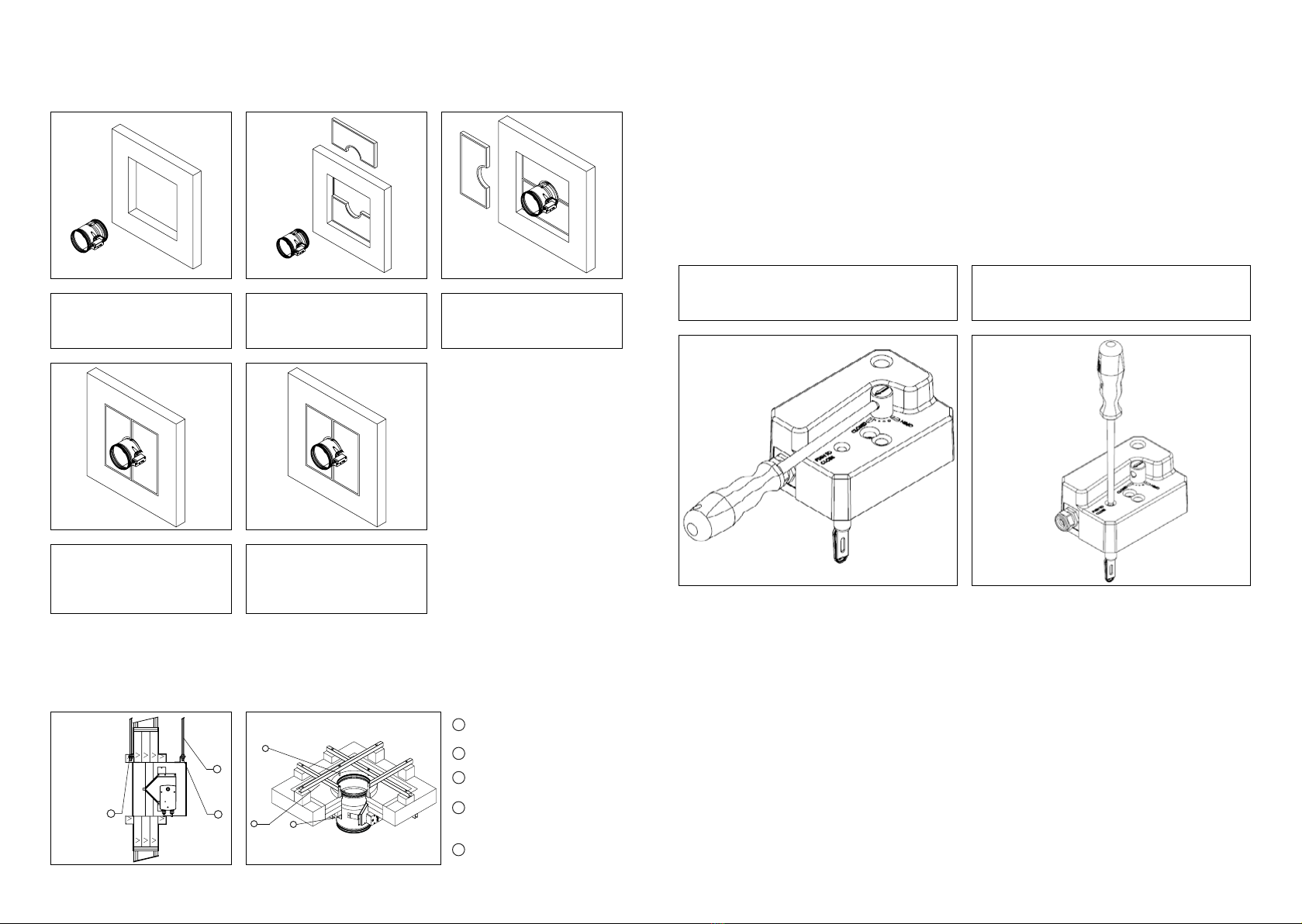

8. OTHER MECHANISMS

Belimo

Operation

Damper is delivered in closed position. When

electric actuator is connected to the power

which is it blocked, the electromotor will stop.

when a power failure occurs. Thermal tripping

the switch on the thermal tripping device will

close damper. When switch on tripping device

is released, the damper will open.

Damper can be opened without connecting

to a voltage with enclosed handle turning in

the direction of the arrow on electric actua

and BFN.

To unlock the electromotor, turn handle clock

release brake for Belimo BFL and BFN. After re

actuator will not move the damper into closed

Type of Belimo actuator BFL24-T BFN24-T BFL230-T BFN230-T BF24-T BF230-T

Nominal

voltage /

power con-

sumption

voltage AC/DC 24V,

50/60Hz AC 24V,

50/60Hz AC 230V,

50/60Hz AC 230V,

50/60Hz AC/DC 24V,

50/60Hz AC 230V,

50/60Hz

opening 2,5 W 4 W 3,5 W 5 W 7 W 8.5 W

holding 0,8 W 1,4 W 1,1 W 2,1 W 2 W 3 W

for wire sizing 4 VA 6 VA 6,5 VA 10 VA 10 VA 11 VA

End switch 1 mA...3 A

(0,5 A), DC 5

V...AC 250V

1 mA...3 A

(0.5 A), DC 5

V...AC 250 V

1 mA...3 A

(0.5 A), DC 5

V...AC 250 V

1 mA...3 A

(0.5 A), DC 5

V...AC 250 V

1 mA...6 A (3

A), DC 5 V...

AC 250 V

1 mA...3 A

(0.5 A), DC 5

V...AC 250 V

Running

time

motor <60 s <60 s <60 s <60 s <120 s <120 s

spring-return ~20 s ~20 s ~20 s ~20 s ~16 s ~16 s

Ambient temperature range min. -30°C, max. 50°C

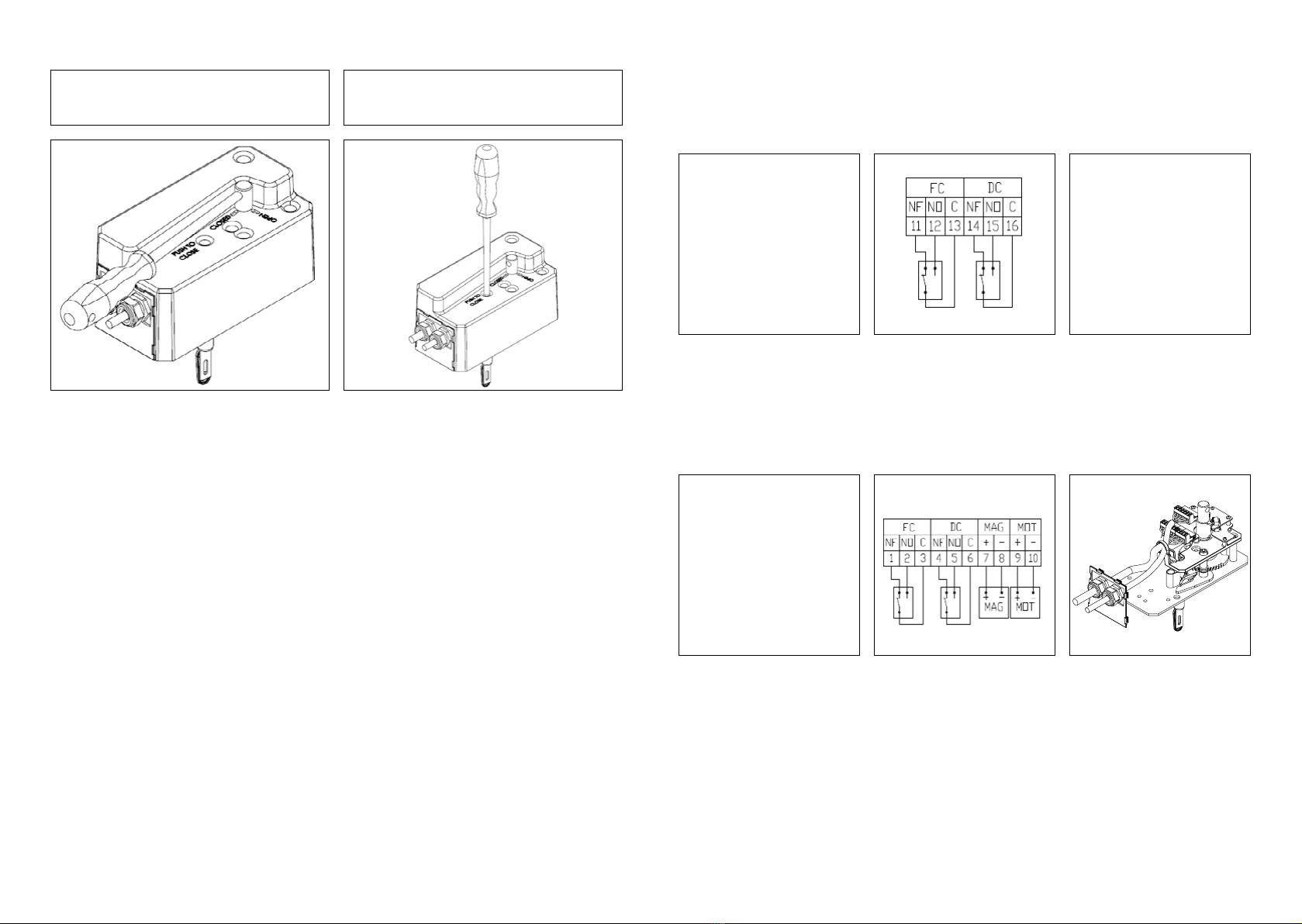

Wiring diagram