OPERATING PROCEDURES

MP34.431

06MAY1

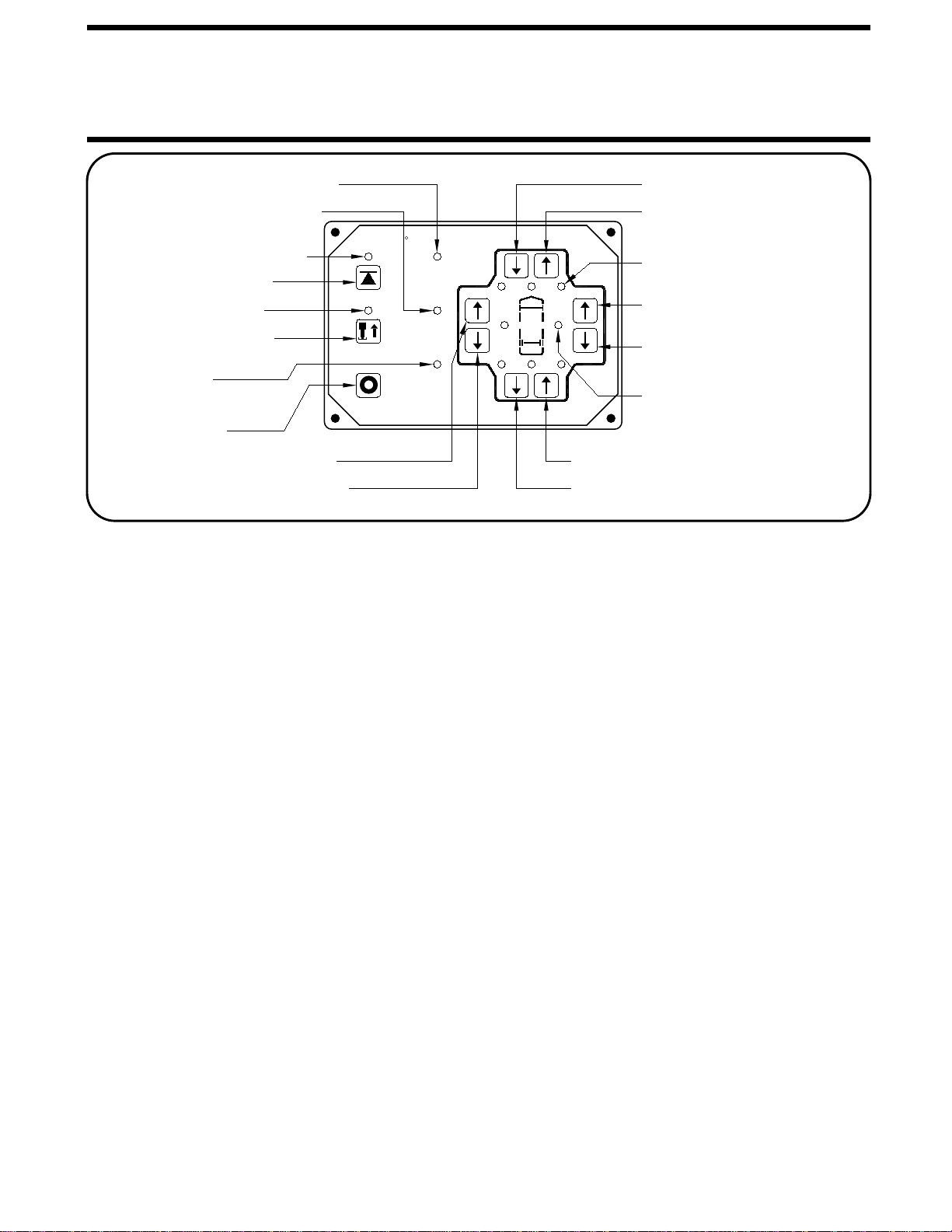

ROOM EXTEND PROCEDURE

CAUTION:

1. Unlock all room-locking devices.

the room remove it before extending the room.

CAUTION:

extend the room.

3. To extend the room, press and hold the

ROOM CONTROL SWITCH in the "EXTEND" position

the operation of the room.

ROOM RETRACT PROCEDURE

2. To retract the room press and hold the

ROOM CONTROL SWITCH in the "RETRACT" position

the operation of the room.

4. Engage all room-locking devices.

IMPORTANT: Room-locking devices should be locked

while traveling.

OPERATING THE ROOM WITH ANY

KEEP PEOPLE AND OBSTRUCTIONS

CLEAR OF ROOM WHEN OPERATING.

CAUTION:

CLEAR OF ROOM WHEN OPERATING.

KEEP PEOPLE AND OBSTRUCTIONS

5. If the room will not retract see the MANUAL ROOM

RETRACT PROCEDURE.

NOTE: The park brake must be set before a room can be

NOTE:

NOTE: If the MANUAL RETRACT WINCH is attached to

NOTE: Make sure there is adequate clearance to fully

NOTE: Releasing the ROOM CONTROL SWITCH will hal

NOTE: Releasing the ROOM CONTROL SWITCH will hal

NOTE: The park brake must be set before a room can be

extended or retracted.

extended or retracted.

ROOM-LOCKING DEVICES LOCKED OR THE MANUAL-

RETRACT WINCH ATTACHED CAN CAUSE PERSONAL

INJURY AND VEHICLE DAMAGE. IT IS THE OPERATOR’S

RESPONSIBILITY TO ENSURE THAT ALL ROOM-LOCKING

DEVICES AND THE MANUAL RETRACT WINCH ARE

DISENGAGED BEFORE OPERATING THE ROOM.

after the room is fully extended or stops moving.

in the "EXTEND" position for more than ten seconds

of the room, do not reverse direction of the room until

after the room is fully extended. This assures proper

Hold the switch to "EXTEND" three or four seconds

pressurization of the cylinders.

Do not hold the ROOM CONTROL SWITCHIMPORTANT:

NOTE:

During normal operation

the room is fully extended. If necessary, the direction

of the room may be reversed, but watch for binding of

the room. If the direction of the room has been

reversed, DO NOT re-extend the room until the room

has been fully retracted.

If either side of the room stops moving, release the

room control switch immediately. DO NOT force the

room. DO NOT reverse direction of the room, contact

HWH Customer Service for assistance 1-800-321-3494.

HWH Customer Service for assistance 1-800-321-3494.

room. DO NOT reverse direction of the room, contact

room control switch immediately. DO NOT force the

If either side of the room stops moving, release the

after the room is fully retracted or stops moving.

in the "RETRACT" position for more than ten seconds

Do not hold the ROOM CONTROL SWITCH

reversed, DO NOT retract the room until the room

the room. If the direction of the room has been

of the room may be reversed, but watch for binding of

the room is fully retracted. If necessary, the direction

of the room, do not reverse direction of the room until

During normal operation

Hold the switch to "RETRACT" three or four seconds

after the room is fully retracted. This assures proper

has been fully extended.

pressurization of the cylinders.

IMPORTANT:

NOTE:

until the room is fully retracted.

until the room is fully extended.

2. Turn the ROOM OPERATOR’S PANEL Key Switch to "ON". 4. Turn the panel Key Switch to "OFF" and remove the Key

to prevent undesired operation of the room.

1. Turn the ROOM OPERATOR’S PANEL Key Switch to "ON".

3. Turn the panel Key Switch to "OFF" and remove the Key

to prevent undesired operation of the room.

Refer to vehicle manufacturer for proper sequence of

room extension and leveling system operation.

Refer to vehicle manufacturer for proper sequence of

room extension and leveling system operation.